Project overview

With an upcoming wedding booked for 5 days time, with no chance of changing the date, we were asked to provide a solution for installing a flooring system to a newly laid concrete floor that was to receive an LVT floor finish and allow the venue to open on time. The area totalled 500sqm.

A site visit was carried out and moisture testing completed on the concrete subfloor. Due to the high levels of moisture present an epoxy surface damp proof membrane was required. The area has large, floor to ceiling windows so the floors would be subject to extremes of temperature. With 5 days to complete the installation and have the venue open, it was all hands to the pump!

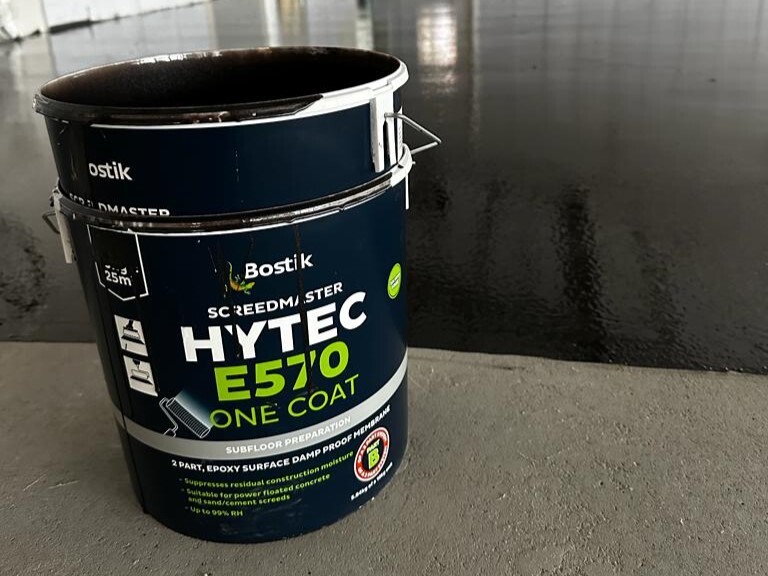

Day 1 – The floors were mechanically prepared and vacuumed then treated to Bostik Hytec E570 One Coat Membrane which was left overnight to dry.

Day 2 – The area was then primed using Bostik Grip A936 Express which was allowed to fully dry before the entire area was treated to 5mm of Bostik SL C510 Pro smoothing compound.

Day 3-4 – The LVT floor covering was adhered to the SL C510 Pro using Bostik Stix A550 Power Elastic throughout due to the fluctuations in temperature the flooring will be subjected to.

Day 5 – The wedding went ahead with no hitches and one happy bride!!

The SL C510 Pro was chosen specifically for this installation due to its speed of drying and also the superior surface finish it provides for LVT flooring. Stix A550 Power Elastic was the adhesive of choice due to its ability to perform in varying temperatures. This venue has now been in operation since February and we have had heatwaves and arctic blasts, the floor is performing impeccably.

The contractor who carried out the works was so impressed with the products and the system that he has now switched all his business over to Bostik.

Products used

Bostik Hytec E570 One Coat Membrane, Bostik Grip A936 Express, Bostik SL C510 Pro, Bostik Stix A550 Power Elastic