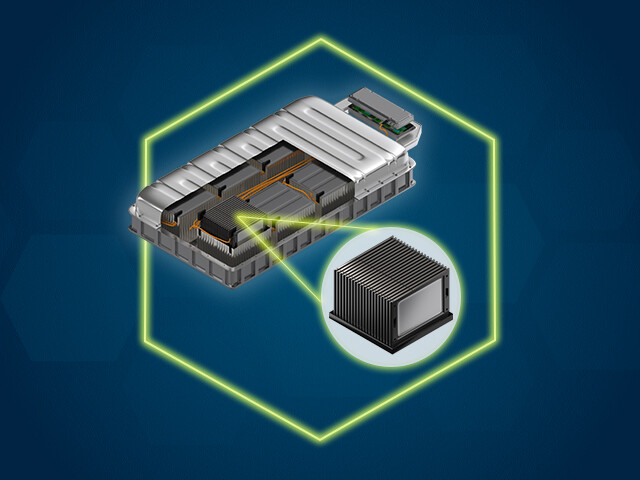

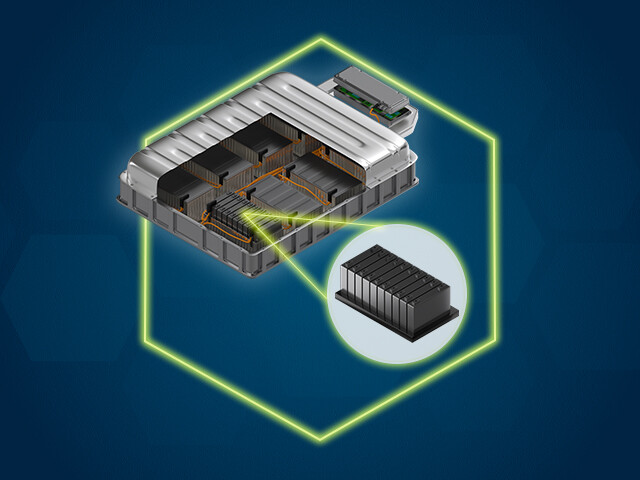

Cylindrical Cell

Adhesives

Smart solutions for cylindrical cells

Bostik’s extensive expertise and innovative solutions, based on a broad portfolio of acrylic technologies, ranging from methyl methacrylate and UV acrylic to UV cyanoacrylates, make it possible to meet all market challenges, offering:

- Multi-substrate adhesion for improved design options across various substrates addressing cell to cell and cell to module bonding needs

- Excellent aging, bonding, and high-temperature resistance performance for enhanced durability

- Good vibration and shock resistance under dynamic conditions for enhanced reliability and safety

- Short open times and no pre-treatment requirements for increased line speeds in fully automated conditions

Featured product: SAF103

Frequently Asked Questions about Cylindrical Cell Adhesives

What are the challenges of cylindrical cell adhesives used in electric vehicles

The efficiency of the assembly line is one of the most critical challenges for the adhesive in the OEM production process. Firstly, a cylindrical cell doesn’t pack as efficiently as prismatic and pouch cells. Due to its circular cross-section, the cylindrical cell pack is larger and heavier than other cells types. Thus, the curing speed at room temperature and the bonding strength (cell-to-cell and cell-to module) are essential characteristics of cylindrical cell adhesion.

Which adhesive technology could be used for cylindrical cell assembly?

You may need an adhesive compatible with a fully automated process, short curing times, and multi-substrate adhesion for the cylindrical cell assembly. Acrylic adhesives (MMA) are suitable thanks to their short setting time, multi-surface bonding, and high bonding strength. Other technologies such as UV curing (UV acrylic, UV cyanoacrylate) can also be used.

What are Methyl Methacrylate MMA adhesives?

Methyl methacrylates (MMA) are structural adhesives adapted to bond metals, plastics, and composites. Bostik’s MMAs are designed to be tough, flexible, easy to use, and are made of resin and hardener. Most MMAs also contain rubber and strengthening agents.

They cure quickly at room temperature and have high bonding strength shortly after application. They also resist shear, peel, and stress. As a result, MMA is a good option for assembling cylindrical cells.

Bostik MMA SAF range mainly consists of unmatched impact resistance and flexibility performance. This is possible thanks to our patented MMA adhesives using specific tailor-made Nanostrength® (Acrylic-block-copolymers tougheners) by Arkema.

What are the key benefits of Bostik's adhesives for cylindrical cell assembly?

Bostik has numerous adhesive technologies used to assemble cylindrical cells for electric vehicles. Our adhesives offer interesting features such as heat resistance and high bonding strength and can significantly improve the safety and life of your batteries. A good selection of adhesives, supported by Bostik specialists, can help you meet your needs.