May 1, 2020 - 10 min

Grease or Anti-Seize: Know the Difference

Grease and anti-seize are popular options for industrial assembly processes. Yet while they both aid in end-product functionality and durability, it’s important to understand their distinct differences.

Smart Options Bostik manufactures Never-Seez®, industry-leading line of anti-seize compounds that:

Grease

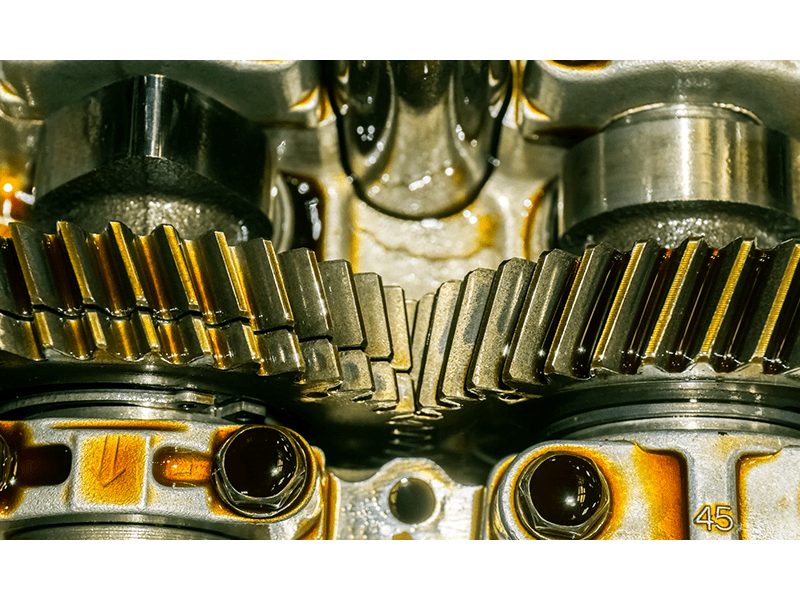

Ideal for fast-moving, low load applications, grease is formulated with a base oil and a thickener. Containing no solids or low solids, grease enables parts, such as high-speed automotive ball bearings, to move rapidly without making contact. However, grease alone is not suitable for extremely high load and/or very high temperature applications. This is because the oil burns off around 400°F, and its film is not strong enough to hold against pressure from asperity contact.Anti-Seize

Designed to convert torque to tightening force more efficiently, anti-seize is formulated with high solids content and a carrier grease. Because of its high solids content, anti-seize can handle high load applications while still providing lubrication and friction reduction. However, anti-seize is not suitable for fast-moving applications, as its high solids content can cause parts to jam. Yet unlike grease, the solid lubricant in anti-seize can withstand high temperatures and protect parts from galling and seizure even under extremely stressful environments. This makes it ideal for many nut, bolt and press fit applications. Refer to following chart for an at-a-glance comparison:| Grease | Anti-Seize |

| No solids or low solids content | High solids content |

| Good for fast-moving, low contact, low pressure applications | Good for slow-moving, extremely high contact and high-pressure applications |

| Typically not suitable for temperatures above 400°F | Suitable for high temperature environments |

- Protects from seizures at high temperatures

- Resists galvanic action

- Prevents galling

- Protects against rust and corrosion