Smart Benefits

Our automotive trim adhesives have been refined over decades of research to provide some of the smartest and quickest bonding solutions in the automotive industry.

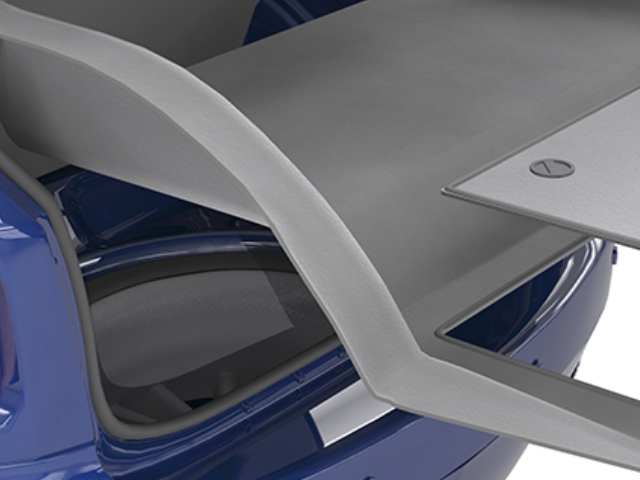

If you’re looking for flexibility, our range of hot melts are compatible with most complex substrates and encompass all forms of molding.

Both our hot melts and reactive solvent-based technologies can be applied by spray or roll coater – minimizing both wastage and drying time.

Extensive technical support is also provided for all our customers. Whether you need to pass an OEM test or minimize the cost per part of your manufacturing procedure, we can help you find the most economical solution.

Technologies:

Reactive Solvent-Based Adhesive

Our reactive solvent-based adhesives work well as an all-purpose bonding agent. The versatility of these adhesives makes them ideal for the broad range of applications required within automotive manufacturing.

Bostik LADH1755, for example, significantly increases ease of application as it can achieve a full bond despite only being sprayed to one side of a molded substrate.

Many of our customers choose reactive solvent-based adhesives due to their clean application, toughness of bond.

When dissolved into a solvent, the polymer reacts by cross-linking, which provides greater creep resistance than typical solvent-based adhesives.

Rubber-Based Adhesive

Our rubber-based adhesives are perfect for use on the interior of the car door panel, and can be used to bond most common automotive substrates, even those that are notoriously difficult.

All our rubber-based technologies are of a medium viscosity and contain pigmentation to increase visibility and accuracy. These products are also suitable for pressure bonding, and some can also be used for vacuum forming.

Most gaskets and sealants are made from rubber-based compounds. Our rubber adhesives ensure your gaskets stay in top condition in terms of water management, sound-dampening, and general resistance to vibration and harshness.

Water-Based Adhesive

If your goal is to achieve lower emissions, our water-based products provide an excellent alternative to solvent-based adhesives. These products significantly reduce the VOC emissions in your manufacturing process.

Low-viscosity compounds also perform consistently well in OEM tests, making water-based adhesives a great way to ensure that your vehicles do not emit volatile chemicals.

This technology will function optimally with a permeable substrate, so if your door panel is composed of different fabrics such as foam or leather, this could be an ideal choice.

Also, through the process of water-based adhesive lamination, you can achieve a laminate for your vehicle that is environmentally friendly and cost-effective (or alternatively, you can use our hot melt adhesives to produce a laminate).

In situations where heat activation is unnecessary or undesirable, it’s also possible to use a water-based adhesive formulation. This way you still achieve a strong bond without the process required by hot melts or automotive trim tape.