E-Mobility

Bostik’s EV Battery Adhesives and Sealants Solutions

Bostik offers cutting-edge adhesive technologies tailored for EV batteries applications:

| Product Type | Key Benefits | Applications |

|---|---|---|

| Thermal Conductive Adhesives | Enhances heat dissipation, prevents overheating | Battery pack assembly, cooling system integration |

| Structural Adhesives | High-strength bonding, vibration resistance | Cell-to-pack assembly, module bonding |

| Sealants | Moisture and dust protection, chemical resistance | Battery housing, electrical insulation |

| Hybrid Adhesives | Combines flexibility and durability | Battery casing, electronic component bonding |

Driving the Future of E-Mobility with Bostik

Bostik’s EV battery adhesives and sealants help manufacturers meet safety, efficiency, and sustainability goals while ensuring long-lasting performance. With innovative bonding solutions, Bostik is shaping the future of electric mobility.

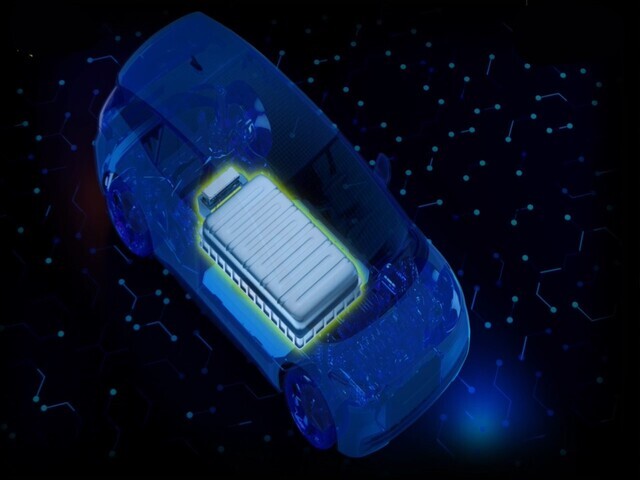

As the automotive industry shifts toward electrification, manufacturers face increasing challenges in battery safety, efficiency, and sustainability. Bostik, a global leader in adhesive and sealant technologies, is at the forefront of this transformation, providing innovative bonding solutions that enhance EV battery performance and longevity.

The Role of Adhesives in EV Battery Technology

EV batteries require advanced materials to ensure structural integrity, thermal management, and electrical insulation. Bostik’s smart adhesives and sealants play a crucial role in:

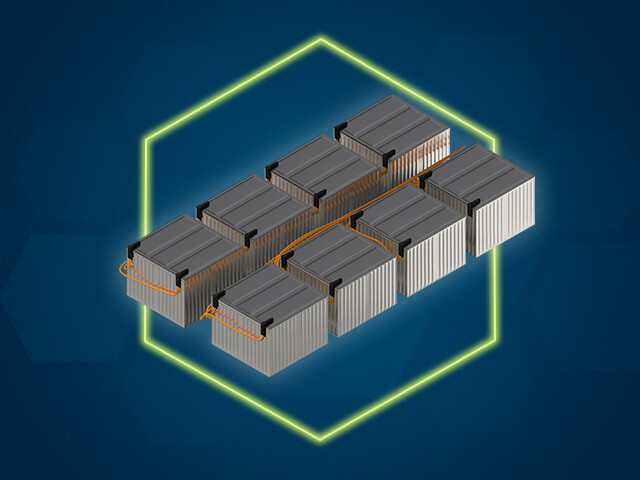

- Battery Cell & Module Assembly: Ensuring strong bonding and mechanical stability.

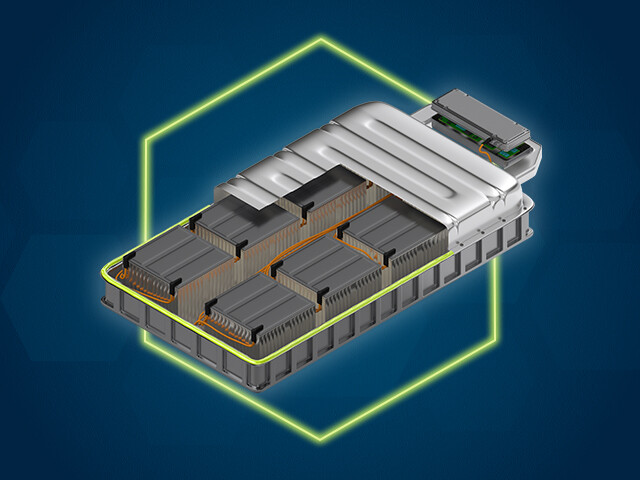

- Battery Pack Integration: Providing thermal protection and shock resistance.

- EV Electronic Components: Enhancing electrical insulation and durability.

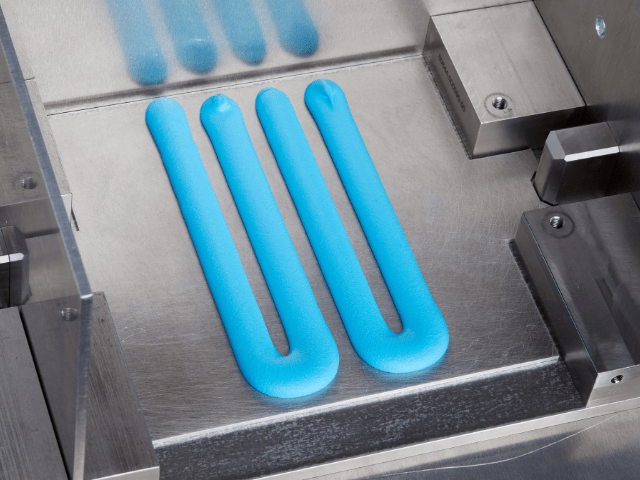

- Battery Cooling Design: Optimizing heat dissipation for efficient thermal management.

Bostik’s Advanced EV Battery Solutions

Bostik offers a range of high-performance adhesives and sealants tailored for EV battery applications, including:

- Thermally Conductive Adhesives: Facilitating efficient heat transfer, preventing overheating.

- Structural Bonding Solutions: Enhancing crash resistance and mechanical durability.

- Liquid Gap Fillers: Ensuring uniform thermal conductivity across battery cells.

- Flame-Retardant Adhesives: Providing fire protection and safety compliance.

Key Benefits of Bostik’s EV Battery Adhesives

- Improved Battery Safety: Reduces thermal runaway risks and enhances fire resistance.

- Enhanced Performance: Supports fast-charging capabilities and energy efficiency.

- Sustainable Solutions: Low VOC emissions, contributing to eco-friendly manufacturing.

- Cost-Effective Production: Enables automated assembly, reducing manufacturing costs.

Industry Trends Driving E-Mobility Innovation

The EV battery market is evolving rapidly, with key trends influencing adhesive development:

- Fast-Charging Infrastructure: Requires advanced thermal management solutions.

- Lightweight Materials: Adhesives replace mechanical fasteners, reducing vehicle weight.

- Sustainability Initiatives: Manufacturers prioritize low-impact materials for greener production.

Bostik’s Commitment to E-Mobility

Bostik continues to lead the charge in EV battery innovation, collaborating with industry experts to develop next-generation adhesive solutions. Their expertise in thermal conductive adhesives ensures high-performance bonding and efficient heat dissipation for modern EV battery designs.

Our E-Mobility – Battery EV Solutions

Frequently Asked Questions

EV battery manufacturing relies on specialized adhesives for structural integrity, thermal management, and sealing. Some common types include:

- Thermally Conductive Adhesives: Used to dissipate heat and improve batteries performance by ensuring efficient thermal connections between components.

- Structural Adhesives: Provide shear and tensile strength, protecting battery modules from impacts, vibrations, and mechanical loads.

- Gasketing & Sealing Adhesives: Help prevent moisture and contaminants from entering battery packs, ensuring longevity and reliability.

- Encapsulation Adhesives: Used to bond and protect individual cells, reducing the risk of thermal runaway.

Bostik specializes in adhesives and sealants designed for various industries, including construction, automotive, and packaging. Here’s how they work:

- Adhesives: These are used to bond two surfaces together permanently. Bostik offers structural adhesives for high-strength applications and pressure-sensitive adhesives for flexible bonding. Their products ensure durability, resistance to environmental factors, and efficient application.

- Sealants: Unlike adhesives, sealants are used to fill gaps and prevent air, water, or contaminants from passing through. Bostik’s sealing solutions provide flexibility, weather resistance, and long-lasting protection for various surfaces.

EV batteries require high-performance bonding and sealing solutions to enhance:

- Thermal management: Prevent overheating and improve battery lifespan.

- Structural integrity: Secure battery modules and protect against vibrations.

- Environmental resistance: Shield against moisture, dust, and chemical exposure.

- Lightweight design: Reduce vehicle weight for improved efficiency.

Pricing varies based on the type of adhesive, application, and volume required. Costs can range from standard industrial adhesives to high-performance thermal management solutions.

Success Stories

Bostik has played a significant role in advancing EV battery technology by providing high-performance adhesives and sealants that enhance safety, durability, and efficiency. Here are some notable success stories:

1. Supporting Leading EV Manufacturers

Bostik collaborates with major automotive OEMs to develop customized adhesive solutions for battery pack assembly, thermal management, and structural bonding. Their smart adhesives help manufacturers meet stringent safety regulations while improving battery longevity and performance.

2. Innovations in Battery Cooling Design

Bostik’s thermal interface materials (TIMs) have been integrated into next-generation EV battery cooling systems, ensuring efficient heat dissipation and preventing thermal runaway. These solutions contribute to faster charging capabilities and extended battery life.

3. Sustainability-Focused Adhesive Solutions

Bostik has developed eco-friendly adhesives that support sustainable battery production. Their low-VOC formulations help manufacturers reduce environmental impact while maintaining high-performance bonding.

4. Collaboration with Arkema for Advanced Battery Technology

Bostik, in partnership with Arkema, has introduced high-performance polymer coatings for battery modules and packs. These coatings provide electrical insulation, thermal conductivity, and mechanical stability, ensuring greater durability and efficiency in EV batteries.

5. Enhancing EV Battery Safety

Bostik’s flame-retardant adhesives have been successfully implemented in EV battery enclosures, providing fire protection and compliance with industry safety standards. These solutions help manufacturers improve passenger safety and battery reliability.

Bostik continues to lead the charge in EV battery innovation, working closely with industry experts to develop next-generation adhesive solutions. You can explore more details on their EV battery adhesives and sealants here. Let me know if you need further insights!

Driving the Future of E-Mobility

- Thermal Management: Prevent Overheating & Improve Battery Lifespan

- Structural Integrity: Secure Battery Modules & Protect Against Vibrations

- Environmental Resistance: Shield Against Moisture, Dust & Chemical Exposure

- Lightweight Design: Reduce Vehicle Weight for Improved Efficiency

- Innovative Bonding & Sealing Technologies