Prismatic Cells

Adhesives

Smart adhesive solutions for prismatic cells assembly

Bostik's innovative prismatic cell adhesives, based on polyurethane (2KPU) technology, address these pain points, offering:

- High bonding strength coupled with high elongation at break (up to 200%) for vibration and shock resistance for enhanced reliability and safety under dynamic conditions

- Strong bonding across surfaces for increased durability and ageing performance

-

Fast curing speed and appropriate open time (5-10 minutes) for streamlined and efficient automated application process

-

Low VOC/emission PU technology for more sustainable approach

Featured product: XPU 18512 AM/B

Frequently Asked Questions about Prismatic Cells Adhesives

What are the challenges of adhesives for prismatic cells in electric vehicle batteries?

Prismatic cells can be packed more efficiently than cylindrical cells due to their shape, making them smaller and lighter, but more expensive, than cylindrical cell packs. However, same as pouch cells, prismatic cells experience more expansion and contraction during charge and discharge than cylindrical cells. Thus, the flexibility is particularly important for the adhesive selection.

Which adhesive technology could be used for prismatic cells assembly?

The adhesives that can be used for the assembly of prismatic cells are two-component polyurethane adhesives (2KPU), HMPSA (Hot Melt Pressure Sensitive Adhesive), and Hot Melt Polyolefin (HMPO).

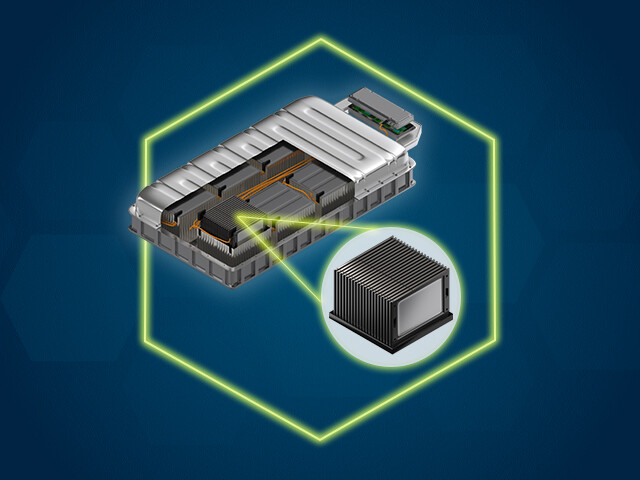

How adhesive can help you to improve battery safety?

Although the cells in the module are fixed to the cooling plate, they sometimes need additional support and protection from the mechanical shock and vibration experienced as the vehicle travels, or if it is involved in a collision.

This support and protection can be provided through the use of adhesive or sealant foams or tapes. Adhesives used in these applications must have sufficient flexibility to allow for expansion and contraction of the cells in the usage cycle and provide high bonding of the cells to the module (side wall end-plate).

What are the advantages of polyurethane adhesive solutions?

Polyurethane has high levels of flexibility, as well as good resistance to UV, adverse weather conditions and cracking. Polyurethane solutions have application in specific markets including sealing, roofing, tiling, aerospace laminating, flexible packaging, upholstery, flooring, automotive production and EV battery.