Sealing Success in Insulated Glass | Double R Glass & Roofing Systems

In today’s insulated glass market, manufacturers face rising energy costs, stricter sustainability targets, and increasing pressure on supply chains. To stay ahead, they need solutions that are not only high-performing but also efficient and future-ready.

That’s exactly what Double R Glass and Roofing Systems Limited, a pioneer in the UK insulated glass (IGU) market found in our adhesive solutions. Since 2000, Double R has been producing high-quality sealed units from their state-of-the-art facility in Northamptonshire — delivering over 4,000 units per week, all featuring Bostik 4000 Hot Melt.

Why Bostik 4000 Hot Melt?

- Exceptional durability and thermal insulation

- Fast, efficient, and safe application

- Proven to extend the lifespan of IGUs

- Fully compatible with automated production lines

Learn more about our IG solutions

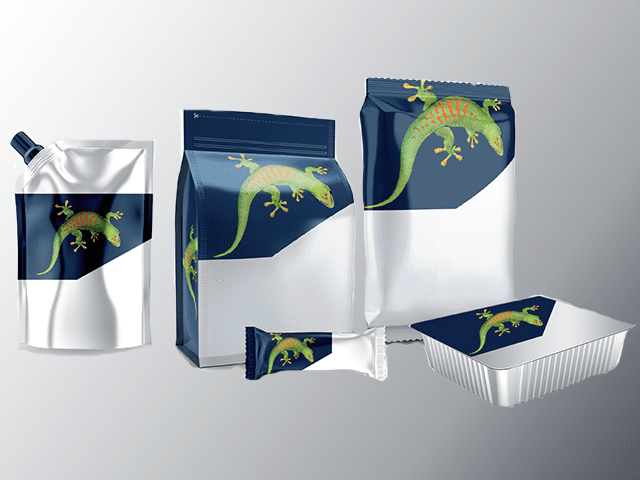

Recyclable, peelable lidding film for packaging | BRÜCKNER MASCHINENBAU

As sustainability pressures mount and regulations tighten, the packaging industry is urgently seeking recyclable, high-performance solutions. One of the biggest challenges lies in balancing material efficiency with sustainability goals, especially in food packaging where functionality is critical.

In response, Bostik and Brückner have joined forces to present a full-service solution for producing recyclable PET peelable lidding films designed for thermoform tray recovery.

Why Bostik & Bruckner solutions?

-

Good hermeticity and Food compliant film

-

Easy peel more convenient while maintaining food safety

-

Good haze and antifogensure content visibility

Learn more about our FLEXIBLE PACKAGING solutions

Linerless label solutions | Optimum Group™ Belona

The labeling industry faces increasing demands to reduce waste, improve operational efficiency, and meet evolving environmental standards. Traditional label formats often generate excess liner waste and require complex logistics and storage.

At Bostik, we’re proud to support this transformation by partnering with companies pioneering linerless label solutions—a more sustainable alternative. By eliminating the liner, these solutions:

- Reduce material waste

- Streamline production and storage

- Lower environmental impact