Adhesives Technology

Hot melt PSAs are formulated with three primary raw materials: polymers, resins, and plasticizers.

- Polymers are the backbone and provide cohesive or internal strength.

- Resins tackify the polymer and provide adhesive strength.

- Plasticizers enable effective wet-out and lower the viscosity for coating. Heat and shear is used to blend these materials in specific amounts to achieve the end use properties needed for each application.

This type of adhesive is suspended in water. It is coated at room temperature, but requires an oven to remove the water. When the adhesive is dry, it remains tacky so can be used in various tape and label applications.

Hot Melt Adhesive is 100% dry content, and does not require drying or curring.

- Peel testing looks at the force needed to break a bond. It measures the strength of an adhesive bond to one or more materials.

- Peel adhesion is the amount of force needed to remove an adhesive from a surface or separate two materials laminated together.

Shear adhesion testing measures the ability of an adhesive to resist debonding over time when a weight is attached.

Shear resistance can be used as an indicator of the cohesive or internal strength of an adhesive. Applications that require high shear performance include durable labels and tapes.

Viscosity measures the internal friction of a liquid in motion. It indicates whether the correct amounts of raw materials were used in manufacturing. Viscosity should be optimized to the application method being used for the best processability.

Method and Process

Slot die is the most common type of coating method used with HMPSAs. Typically hot melts are transfer coated from the release liner to the face stock to achieve the smoothest surface on the adhesive for bonding.

Roll coating or gravure printing may be used to pattern coat hot melts.

Hot melt adhesives will degrade with extended time at elevated temperature when the line is not running. Degradation can negatively affect the appearance, processability, and performance of a HMPSA.

To prevent producing PSA labels or tapes that are out of specification, it is important to control the temperature of the melt tank, hose, and coating head during equipment related down time.

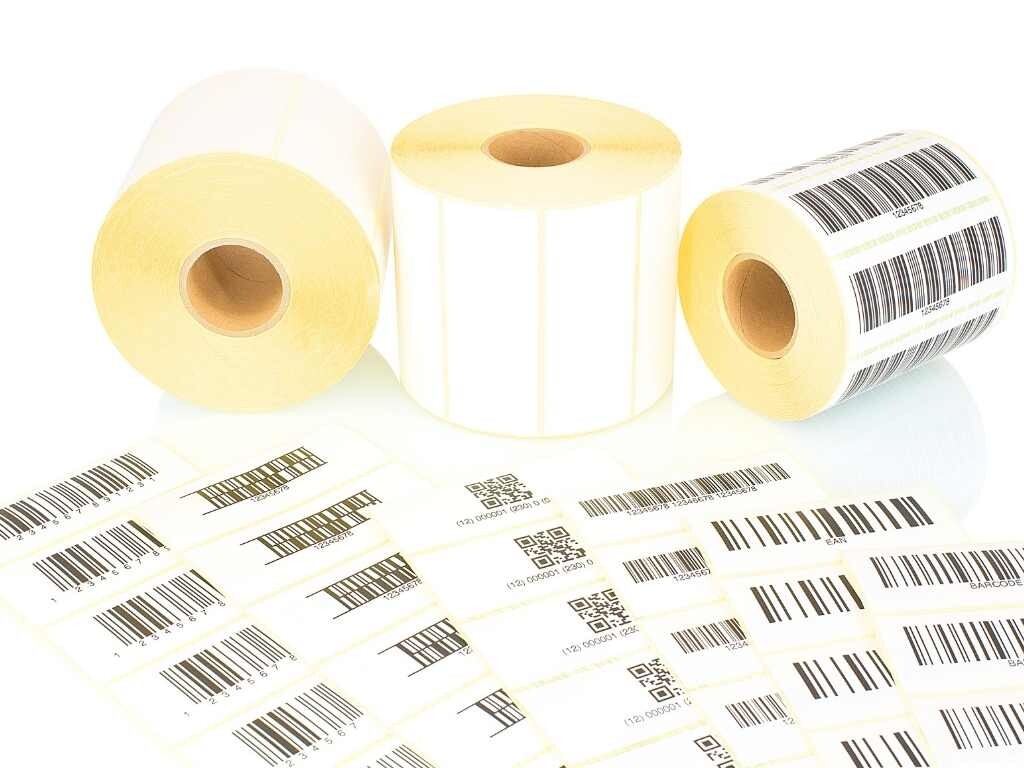

Linerless labels allow you to reduce waste. They are similar to tapes in that silicone is coated on the surface of face stock, eliminating the need for a separate release liner. Along with reducing waste, linerless labels offer operational and inventory efficiencies.

Linerless labels with Bostik hot melt adhesives can be used in e-commerce, grocery weigh scale, and quick service restaurant applications.

Scope of Applications

Hot melt PSAs can be formulated to have high tack even at low application temperatures.

Refrigerator and freezer grade hot melts will be capable of making a quick, strong bond to different surfaces even in the presence of moisture or frost.

Bostik has HMPSAs for these cold temperature applications as well as other end uses where low temperature is critical.