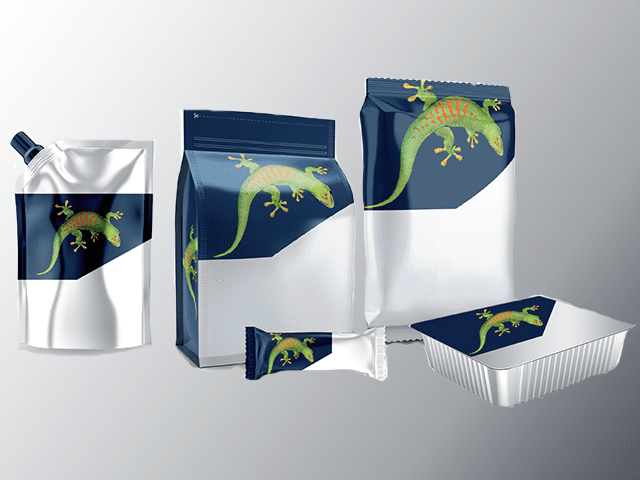

VITEL™ Copolyester Resins - Heat Seal & Coating Solutions for Packaging

Modern packaging faces increasing demands for:

- Recyclability and Circularity: Regulations in EMEA require packaging to be compatible with recycling streams, especially PET-based structures.

- Food Safety Compliance: Adhesives must be BPA-free, halogen-free, and antimony-free while meeting EU food contact standards.

- Performance Across Conditions: From refrigerated APET trays to dual-ovenable CPET solutions, adhesives must withstand extreme temperatures.

- Operational Efficiency: Converters need easy-to-process adhesives that reduce waste and improve line speed without compromising bond strength.

VITEL™ addresses these challenges by offering versatile solutions for heat seal layers, can coatings, and laminating adhesives that meet sustainability and performance requirements.

Discover our copolyester resins – VITELTM

Balanced Performance for Modern Packaging

VITEL™ copolyester resins deliver a perfect balance of properties for demanding packaging applications.

- Offering flexibility in low temperatures and resistance in high temperatures: they ensure reliable performance throughout the supply chain, from frozen storage to oven-ready packaging.

- Versatile Formulation: VITEL™ can be blended or used alone, depending on your application needs. To enhance durability, you can cure or cross-link them, which improves chemical resistance to coatings and primers.

- Exceptional Adhesion: Designed for strong bonding on PET films, ensuring secure seals and consistent lamination.

- More Sustainable: BPA, antimony and halogen free; utilize sustainable raw materials; compostable.

- Recyclability Certification: Based on a recyclability assessment conducted by Plastic Sense Foundation, selected grades (V1200, V2200, V2700, V1900 series) are certified as compliant with PET tray and lid recycling guidelines when used as sealing layers.

Zoom on VITEL™ Resins

To meet diverse packaging needs, VITEL™ offers three specialized product families. Each engineered for specific applications in heat seal, ink binder, primer, interior can coat and lamination. These ranges provide tailored performance, ensuring optimal adhesion and processability.

Extrudable Sealing: VITEL™ 1000 series, ready to use by extrusion and also suitable for formulating Heat sealable/peelable

- Amorphous & semi crystalline

- Glass transition (Tg) from -9°C to 70°C

- Limited solubility

All Purpose Sealing & Coating: VITEL™ 2000 series, solvent based resins, suitable for formulating Heat sealable

- Amorphous

- Glass transition (Tg) from 50°C to 69°C

- Good solubility

Laminating: VITEL™ Laminating, solvent based, suitable for formulating

- Amorphous

- Glass transition (Tg) from -15°C to 21°C

- Laminating adhesive

- High adhesion on metal

Why choose VITELTM from Bostik?

Bostik is a global leader in adhesive technologies. Bostik has worked closely with our customers for many years. We have built a strong level of expertise in many packaging applications.

- Performance: VITEL™ is designed for heat seal, coating, and lamination. It works well in extreme conditions from –40°C to +70°C. VITEL™ also provides custom solutions for different packaging types.

- Innovation: Get tailored solutions from our extensive portfolio, encompassing all technologies from standard to high performance. We meet your technical requirements while aligning with local standards to achieve your regulatory and sustainability goals.

- Expert Support: our technical support team are always ready to assist you with adhesive selection and on-site support.

- Global footprint: we offer comprehensive services across all regions. Our global manufacturing footprint ensures we can serve all your regions effectively, supported by expanded manufacturing capacities in worldwide