Apr 3, 2019 - 10 min

How to Know a Packaging Line Assessment is Right for You

We understand that it can be difficult to produce more packages at a faster rate while adhering to cost constraints and sustainability requirements. It can be even more difficult when production downtime occurs or material issues arise. Fortunately, a packaging line assessment can help alleviate worries and avoid potential problems. Find out what an assessment entails to consider if one right for you.

What a Line Assessment Entails

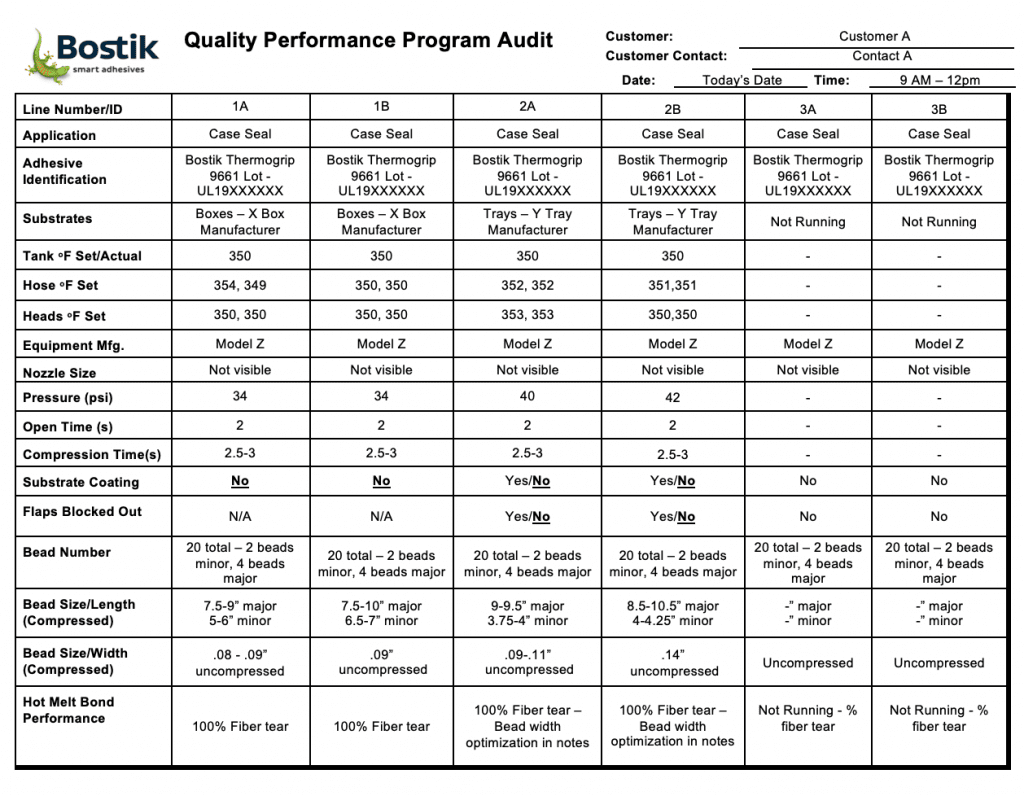

During a line assessment, a Bostik expert will visit your plant and work with you to understand your current and desired state production line needs. In particular, the expert will assess existing processes, including your:

- Equipment settings (temperature, line speed, etc.)

- Adhesive coat weight

- Fiber tear rate

Once the expert has a clear idea of your current processes, our team will identify recommended optimizations for your production line. These can include:

- Adjusting the equipment settings

- Recommending a different adhesive

- Advising on proper maintenance and operational procedures

Additionally, our team will start benchmarking your data, so you can see how your production line improves overtime as adjustments are made.

Why a Line Assessment is Valuable

In addition to identifying problems and offering solutions, a packaging line assessment:

- Alleviates your worry: You can focus solely on keeping your plant running smoothly and efficiently. Our Bostik expert will be able to address and resolve problems for you.

- Shows your plant’s value to your company: As many plants must address cost savings initiatives, a line assessment helps show specifically what is being done to meet those needs. For example, it can yield:

- Reduced adhesive consumption

- Reduced adhesive SKUs

- Improved equipment efficiency

- Benchmarks current and future data: Line assessment also serve as a great tool to see progress over time as optimizations are made.

Considering a line audit? Request one today, and start alleviating your worries tomorrow!