Jul 14, 2020 - 10 min

5 Reasons Your Packaging Hot Melt Adhesive Won't Stick

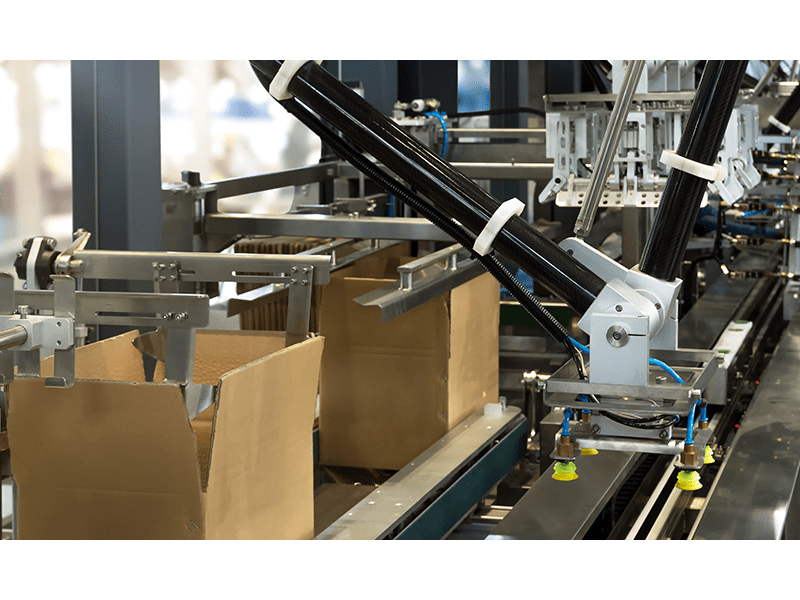

As a package manufacturer, you likely want your case and carton sealing processes to be efficient, effective and worry-free so as to keep production lines moving. However, if your packaging hot melt adhesive fails to sufficiently bond corrugated paper substrates, it can be frustrating and time-consuming to try and decipher the root cause of the problem.

Here are five reasons why your packaging hot melt adhesive may fail to bond substrates together.

- Your Compression Level is Incorrect

In case and carton sealing, compression, or force, is key to achieving a successful bond. If you’re experiencing adhesive failure, it may be because your compression level is incorrect. This means not enough downforce is able to be applied, and the adhesive is unable to sufficiently penetrate the substrate. Be sure to apply the right level of compression to achieve a proper bond without impacting substrate performance.

2. Your Application Temperature Needs to be Adjusted

In colder months, the temperature of the corrugated substrate itself may be low enough to set the packaging hot melt adhesive too quickly during production before you’re ready to bond. Ensure your substrate and adhesive are both at ideal temperature levels to allow for sufficient cure time.

3. Your Adhesive Properties Have Been Altered

If your packaging hot melt adhesive properties have been altered through thermal or oxidative degradation, it’s likely your substrates will fail to bond. This is because the alteration causes charring, which is when the adhesive hardens and will not flow onto the substrate. To ensure your adhesive properties aren’t altered during the application process, refer to your product’s TDS, and follow the handling instructions.

4. Your Adhesive is Unable to Sufficiently Wet Out

Today, many corrugated packaging substrates use highly recycled content, which result in increasingly shorter paper fibers. These shorter paper fibers can make it difficult for packaging hot melt adhesives to sufficiently wet out and achieve a bond. If you’re experiencing adhesive failure with highly recycled corrugate, consider an adhesive formulated specifically for challenging substrates.

5. Your Adhesive Flow is Uneven

When using a nozzle to apply your packaging hot melt adhesive, an uneven flow can cause adhesive failure. There may be too much or too little adhesive in certain areas. Ensure your nozzle and chosen adhesive are compatible so that the right amount of adhesive flows through and is consistently dispensed every time.

Contact a Bostik expert today to determine the right hot melt adhesive for your corrugated paper applications. You can also check out these other relevant case and carton sealing tips: