Jan 8, 2021 - 10 min

What You Need to Know to Easily Manufacture Food-Safe Packaging

Proper food packaging is critical to ensuring a product will be safe to eat after being purchased. However, we understand it can be difficult to address food-safe packaging needs during the manufacturing process, given the many regulations that must be addressed. Below are several items to help make it easier.

Your Packaging Must Protect Contents from Germs and Bacteria

Food packaging’s main function is to decrease the chances of foodborne illness. By reducing the number of surfaces that food comes in contact with, packaging can help reduce the spread of germs and bacteria.

To increase food hygiene in your production process and in the packaging itself, consider the following criteria:

- Facility cleanliness: Your production facility should maintain cleanliness to prevent bacteria and germs from contacting the food packaging and eventually the food itself. Stick to regular equipment maintenance and cleaning schedules to eliminate unwanted germs in the facility.You may also want to implement contamination detection equipment to further monitor potential bacteria growth in your packaging.

- Food-bacteria relationship: Some packaged foods are more prone to bacterial growth than others. Raw meat, fruits and vegetables are most susceptible to contamination. Incorporating antimicrobial additives on the inside of the packaging can reduce the development

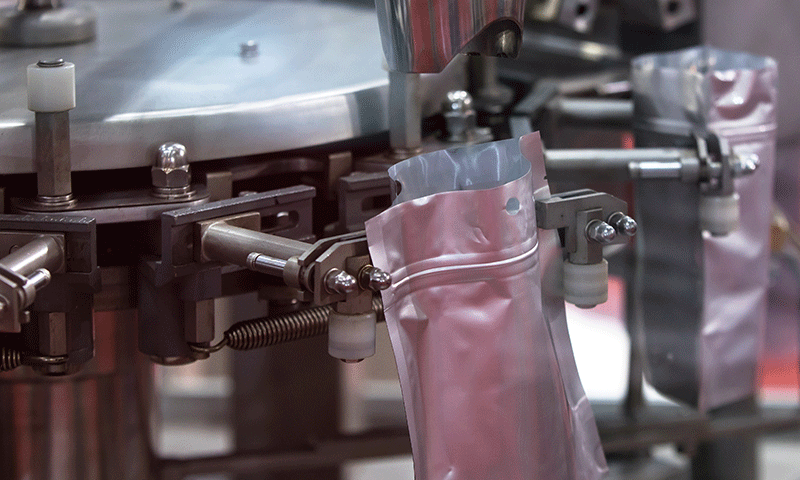

- Effective closures: Ensuring that a package stays closed can prevent germs from contacting the food. Closures should also alert a consumer if the packaging has been tampered with. Tear-away strips on zippered pouches or induction seal liners on bottles can help a consumer easily determine if a package has been opened.

Your Packaging Must Help Maintain Freshness

Food packaging can help extend the product’s shelf life, keeping consumers safe from spoiled food and reducing waste. The packaging also preserves the product’s overall appearance, making the product more visually attractive to consumers and increasing sales.

Every type of food has different needs to maintain freshness over time. To create packaging that meets the food’s needs, consider the following criteria:

- Storage environment: If the package will be stored in a cold environment, it should maintain performance despite freezing temperatures. Some substrates, like paper, may dissolve or deform when exposed to moisture from condensation. Alternatives like polypropylene plastics or wax-coated cardboard can resist deformation in these conditions.

- Durability: The packaging should remain intact from production to the point of sale. Holes, tears or cracks in the packaging can cause the food to spoil faster. Polyethylene terephthalate is a popular packaging material known for its durability. It is a versatile material and can be used in bottles, tubs, bags, wrappers and more.

- Airflow: Some produce packaging can have ventilated packaging, while other foods like bread and meat need oxygen barriers to prevent spoilage. You can increase the oxygen barrier in packaging by incorporating laminates or biaxial orientation, a process which improves the toughness and barrier properties of plastic substrates.

Your Packaging Must Minimize Chemical Migration

Certain packaging material compositions impact the likelihood of chemical migration. If a packaging material or component migrates into the packaged food, it is considered a food additive and must be previously cleared by the FDA , or a Food Contact Notification must be filed for approval by FDA. This approval ensures that if chemical migration occurs between the package and its contents, the food’s color, taste and safety will not be affected.

Be aware of how these factors can increase chemical migration in your packaging:

- Packaging materials – Certain materials are more porous than others, which can increase migration as more chemicals from the outside of the package—like printing ink—can pass through the packaging and onto the contents.

- Food composition – Fatty foods pull more chemicals from packaging, resulting in higher chemical migration.

- Storage time – In some instances, the longer the food stays in its package, the more migration may occur.

- Package-to-contents proportions – Smaller-size packaging has a larger surface to volume ratio. The more contact the contents have with the packaging, the likelihood of migration increases.

Monitoring how these factors impact your packaging can be made easier with safety testing. In a testing environment, you can set up specific conditions for your product to examine how much chemical migration will occur. By examining these criteria and adjusting your packaging as needed, you can ensure your packaging will pass FDA regulations for chemical migration.

There are many factors to consider when creating food-safe packaging. Fortunately, selecting the right adhesive can help you achieve packaging that easily answers food safety concerns. Bostik offers solutions that can help you create packaging that addresses the factors listed above. Contact a Bostik representative today to learn how adhesives can help you achieve food-safe packaging.

Learn more about our solutions for food packaging with this relevant content: