Jan 21, 2021 - 10 min

Marine Window Installation: How To Make Marine Window Glazing Easy

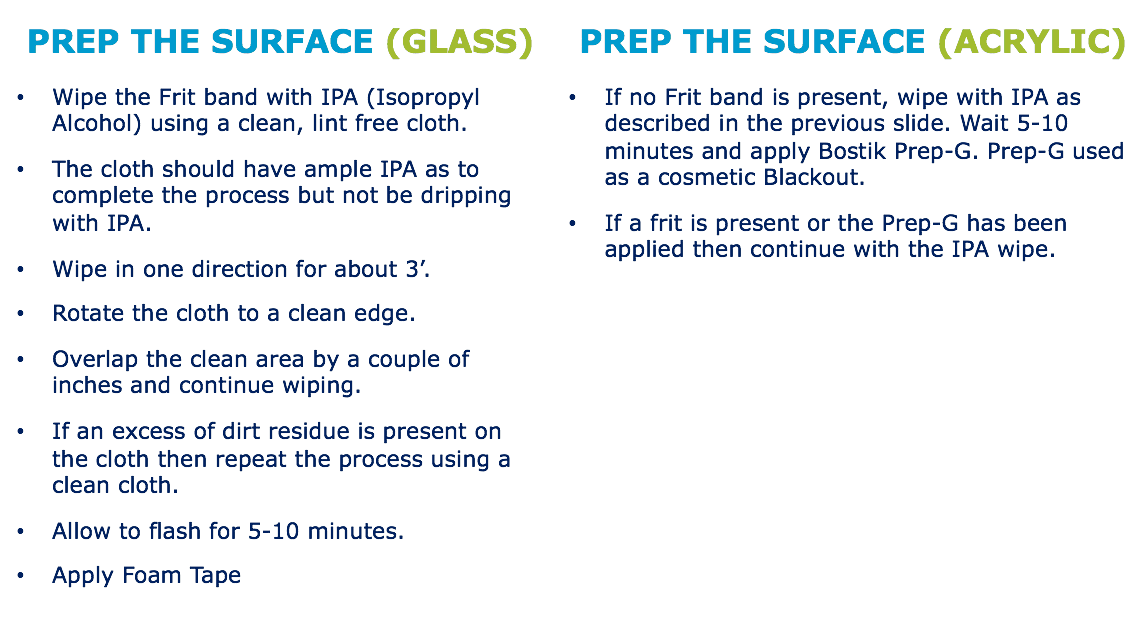

As boats are being built with increasingly bigger windows, marine window bonding has never been more important for proper window performance, security and durability. Follow these tips to ensure your marine window glazing process is done correctly. Step #1: Inspect the Substrate Before you begin the marine window glazing process, it’s important to visually inspect the glass or acrylic to which you’ll bond. Ensure there are no defects or damage to it. If there are, get a new substrate and repeat the process. Failure to properly inspect the surface could result in bond failure. Step #2: Ensure Proper Fit It’s also a good idea to ensure the substrate will fit properly in the window opening once bonded. To test ahead of time:

- Use spacers or shims to replicate the proper, compressed adhesive thickness and the spacing around the perimeter of the window substrate.

- Place the part into the window opening to ensure proper fit and spacing.

Step #4: Apply the Adhesive Now you’re ready to apply the adhesive. Be sure to apply it in a “v”-shaped bead and per the design specification directive for the given vessel. It can be placed directly on the substrate or on the vessel. Step #5: Set the Substrate When setting the glass or acrylic substrate, ensure that all spacers are set and conform to the vessel’s design specification. Press the substrate firmly into the adhesive, but be careful not to over compress the adhesive bead. Avoid moving the glass or acrylic, and do not tap or hit it. Be sure to hold the glass or acrylic in place as the adhesive cures. Step #6: Finalize Once the adhesive is cured and the fixtures are removed, finalize the process by filling the perimeter gap between the glass or acrylic. For more information on proper application tips and marine window glazing solutions, contact us today.