Mar 7, 2022 - 10 min

6 Ways To Know If A Web Adhesive Is Right For Your End-Use Application

While web adhesives offer an easy, uniform bonding solution for many durable goods applications, it’s important to ensure they are suited for your specific needs first. This adhesive requirements building tool outlines seven key questions you should ask yourself to determine if a Bostik web adhesive is right for your end-use application.

IS A WEB ADHESIVE RIGHT FOR YOU?

1. What are your OEM Web Adhesive specifications?

Your adhesive must meet your OEM specifications, such as:

- Environmental cycle testing

- Heat aging

- Performance requirements

If not, the adhesive may fail, and your end-use application will experience possible quality, safety and performance issues.

Bostik’s web adhesives are designed to meet specifications for various applications, including:

- Headliners

- Door panels

- Transportation flooring

- Seating upholstery

- Textiles

In particular, they maintain performance in temperatures ranging from -22°F (-30°C) to 311°F (155°C).

Refer to your OEM specifications, and talk to your adhesive supplier to assess whether or not your desired adhesive will meet them.

2. What is your assembly process cycle time?

Your chosen adhesive also needs to keep up with your required cycle time. For example, if you need to manufacture 60 seats in one hour, then one seat will need to be completed every minute. Your chosen adhesive takes time to be applied before moving from one seat to the next.

Bostik’s web adhesives are applied with heat and pressure and then cool down to form a robust bond between the two substrates. Cycle time of this aspect must be considered when reviewing the total assembly process.

Further, Bostik offers products that cover a wide range of melt points, from 167°F (75°C) to 329°F (165°C), to fit into the desired process parameters.

Discuss your cycle time and assembly speeds with your adhesive supplier to ensure your chosen adhesive’s set up time can address it.

3. What adhesive requirements do you have?

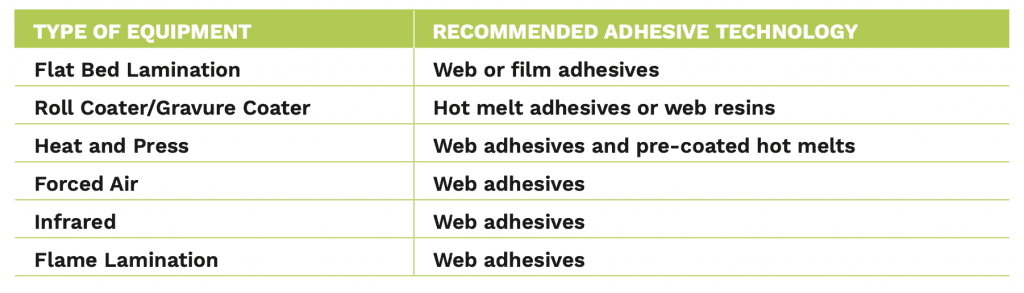

Not every type of adhesive is suited for every type of equipment. Refer to this chart for ideal adhesive and equipment combinations based on your production processes:

4. What substrates are you bonding together?

In addition to assessing your equipment, consider what substrates you’re bonding together. This will also determine the ideal adhesive technology.

Bostik’s web adhesives are formulated to bond to a variety of substrates, such as:

• Metals

• Composites

• Fabrics

• Urethane foams

5. What adhesive coat weight do you need?

Your adhesive’s coat weight plays an important role in overall part performance. If the coat weight is too little, there will be insufficient bonds. On the other hand, if the coat weight is too high, the adhesive can bleed through to the surface. This is because coat weight depends on a substrate’s thickness, porosity and part configuration.

For example, when bonding porous substrates together, such as foam to fabric, an appropriate coat weight will need to be applied to account for substrate porosity. When bonding metals, a thinner coat weight is sufficient, because the adhesive does not penetrate through the substrate.

Another aspect to consider is the final configuration the part itself. If the part has any areas with a deep draws, this could require added coat weight for a proper bond.

Ultimately, finding the ideal coat weight often can be trial and error. To make the testing process easier, Bostik’s web adhesives are readily available in a range of coat weights, from 12 to 100 grams. Further, our in-house testing capabilities enable us to determine the proper coat weight for you, decreasing trial downtime at your plant.

6. What are your company's objectives?

It’s also important to ensure your chosen adhesive aligns with your company’s overall objectives. Bostik’s web adhesives are:

- Safe for workers

- Environmentally friendly

- Easy and fast to apply

Further, as an Arkema company, Bostik is vertically integrated in the production of polyester and polyamide resins. This capability sets us apart from the competition and allows us to more easily meet your needs around the globe.

Think Bostik’s web adhesives might be right for you? Contact an expert today to get started.

Contact a Bostik Expert Today!

If you are interested in learning more about web adhesives, please click here to request a Technical Data Sheet or speak with a Bostik expert today.