Apr 29, 2024 - 3-5 Minutes

5 Primary Applications for Hot Melt Adhesives in Absorbent Hygiene Products

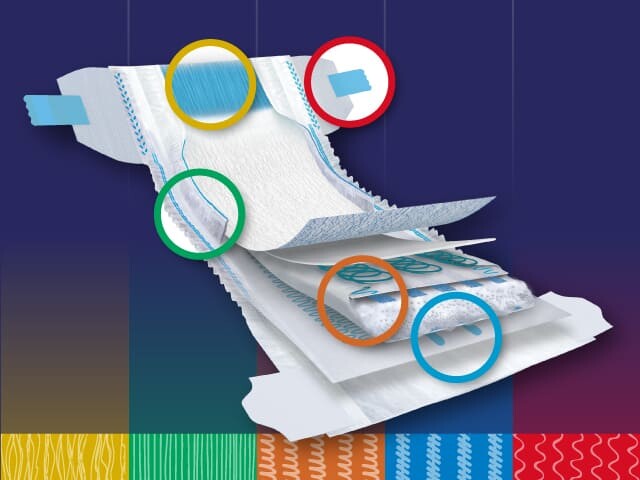

The hot melt glues used in diapers and pads fall into five basic categories: Adhesives for construction, elastic attachment, core, and pad attachment, as well as hot melt wetness indicators (HMWI). Each has its own purpose, functions, attributes, and typical characteristics.

Year after year, baby care, period care, and adult incontinence articles become more complex. Evolving designs. New materials. Expanded functionality. And let’s not forget: Enhanced features for health and sustainability.

Choosing the right adhesives can help to accommodate these and future changes in product design.

The five primary applications for absorbent hygiene adhesives

In general, the hot melts used in diapers and pads fall into five basic categories:

- Construction adhesives

- Elastic attachment adhesives

- Core adhesives

- Pad attachment adhesives

- Hot melt wetness indicators

Each application typically requires certain attributes to perform its function. The exact needs can also vary, based on specifics of product design and materials used. For example, no single adhesive will satisfy the needs of all core types.

Understanding the basics of what is needed in each adhesive application is valuable for enhancing product performance and the consumers’ experience in use.

Construction adhesives: Supporting structural integrity

The number of bonds between nonwovens and other components varies by product type and complexity. In diapers, construction adhesives may fulfill upwards of a dozen specific tasks. These include, but are not limited to:

- Helping prevent absorbent core shifting

- Holding the acquisition distribution layer (ADL) in place

- Bonding materials to prevent shifting or failure

- Fixing the frontal tape

- Attaching the topsheet to the cuff

- Bonding the backsheet nonwoven to the barrier film

- Assuring the end seal bonding

Absorbent hygiene manufacturers generally look for hot melt adhesives that support the integrity of the finished article before, during, and after use. One classic attribute is peel strength. Shear resistance may also be required in certain instances.

Although manufacturers may use construction adhesives for certain roles in traditional cores, it is not always advised. Specific core adhesives are able to provide more targeted attributes to ensure they function as intended.

Core adhesives: Forming and stabilizing the core matrix

Two overarching trends in the hygiene core are increasing absorbency and reducing thickness. The introduction of SAP (superabsorbent polymer) marked a giant step forward in both.

Since that first appearance, the ratio of SAP to fluff has continued to rise. New core designs have also entered the market. These thinner cores support enhanced comfort in all product types. In articles designed for adult use, slimmer profiles also support discretion. In many cases, using the right adhesives made these innovations possible.

In addition to any core-related tasks above, core adhesives are used for:

- Stabilizing the fluff/SAP (or SAP only) core matrix

- Sealing the core wrap

- Adhering the topsheet and bottom layer to create the channel core formation

- Stabilizing SAP on the fluffy nonwoven for production and use in compound/pre-compound cores

Together, these tasks support core integrity and performance, which helps enable full absorption and rewet protection. Regardless of core design, the result is improved comfort, protection, and skin health for the wearer.

The add-on levels and application methods also impact performance of your nonwoven hygiene core adhesive. Bostik’s experts can share valuable information to help you meet your target performance goals effectively and efficiently.

Elastic attachment adhesives: A firm but flexible hold

More than ever, today’s diapers for babies and adults often use elastic strands to support comfort, fit, and leak protection. To function as intended, the adhesive must hold them firmly in place while allowing the strands to stretch and contract. Common uses include:

- Waist and belly elastics — to help provide a comfortable fit while ensuring the diaper stays in place

- Leg and cuff elastics — to positively impact fit, as well as support the absorbent core by helping to contain leaks

In general, elastic attachment adhesives need to demonstrate high shear strength and creep resistance. Other attributes commonly desired include skin-friendly and latex-free formulations.

Pad attachment adhesives: Keeping products where they are needed

With most absorbent hygiene products, the adhesives used are not visible to the consumer. Not so with pad attachment for certain period care and incontinence products. Anyone who uses them is quite aware of the adhesive and how well it performs. Failures can be quite embarrassing to the pad user and may affect their brand loyalty.

At first glance, they only have a single purpose. However, the reality is more complex. Consumers expect the pad’s fastening adhesive to:

- Provide secure pad positioning, discreet wear, and leak prevention

- Be easy to attach and adjust

- Adhere to a variety of underwear fabrics without slipping or bunching

- Stay in place throughout daily and nightly movements

- Detach easily and quietly after use

- Remove without leaving adhesive residue, regardless of underwear or pad material

Initial and in-use peel have traditionally been used as a measure of an adhesive’s ability to hold a pad in place. Because of this, product manufacturers seek options with peel performance within designated ranges.

However, these numbers alone do not necessarily equate to positive or negative consumer ratings. Another method, Bostik’s patented Staybility™ testing, can also evaluate a positioning adhesive’s stay-in-place performance.

Hot melt wetness indicators (HMWI): Enabling convenience and skin health

The HMWI is unique among the uses of hot melt adhesives in absorbent hygiene. Instead of bonding two or more materials together, it bonds to only one. The material’s true purpose rests in its other properties.

Hot melt wetness indicators detect the presence of urine or feces and offer visual leak detection. They typically rely on an ingredient that shifts in color when exposed to the insult. One common option shifts from yellow to blue in the presence of higher pH levels.

These visual indicators have become increasingly popular in baby diapers. They also support caregiver efficiency in care facilities when used for hygiene management of adult incontinence.

To work effectively, HMWI must demonstrate several attributes:

- Fast and clear color change after insult. It should be easily visible, even in dim light, such as when the baby, incontinent adult, or patient is sleeping.

- Resistance to humidity. This helps prevent premature or partial indications during processing and storage, or even in use before insult.

- Reliable processability. HMWI should process cleanly on the production lines and apply neatly to the substrate.

- Thermal stability. The indicator must function even if the hot melt spends several days in production line melt tanks. (This is not uncommon, as often very little is used per diaper.)

Advancing sustainability: An attribute that crosses all applications

As the industry works to achieve a more circular model, manufacturers look for sustainable options that support their goals for corporate social responsibility. Attributes they look for include:

- Bio-sourced and bio-based ingredients

- Material compatibility with natural substrates, including cotton, bamboo, and other bio-based materials

- Adhesives that help enable product recycling or industrial composting through biodegradable formulations or simplified debonding

Expert advice for choosing the right hot melt adhesive

You put careful thought into crafting your products and brand. Each component has a specific function. That’s why ensuring article integrity and performance to meet consumer expectations is so valuable. Learn more about how hot melt adhesives from Bostik can support your product designs and business goals.

Request a meeting with one of our absorbent hygiene adhesive experts today.

©2024 Bostik, Inc. All Rights Reserved

All information contained herein is believed to be accurate as of the date of publication, is provided “as-is” and is subject to change without notice. To review our full U.S. Legal Disclaimer, visit: https://bostik.com/us/en_US/privacy-policy/legal-disclaimer

See also

Back to all articles- Disposable Hygiene

What Millennial Mothers Expect from Sustainable Brands with Amrita Saigal

- Disposable Hygiene

Presenting: Transition(s) with Susie Hewson and Bostik Talks with Jack Hughes

- Disposable Hygiene