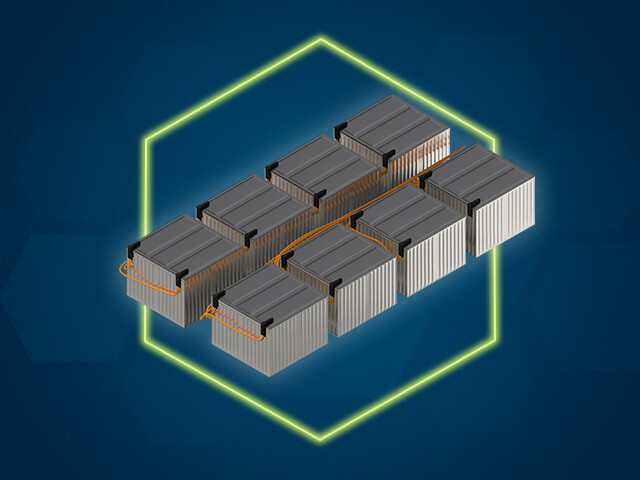

EV Battery Pack Adhesives

How Bostik’s EV Battery Pack Adhesives Help You

Based on cyanoacrylate, methyl methacrylate (MMA) and polyurethane (PU) technologies, our experts formulated adhesives for EV battery pack manufacturing so that they can offer attributes including:

- Ability to fill small gaps (of 5 mm) to reduce failure likelihood

- Vibration resistance to improve durability and longevity

- Strong bonds in <1 minute* and high strength after 5 minutes* to streamline efficiencies

Find out how our EV battery pack adhesives help you!

*based on internal testing

The Bostik Difference

When choosing a Bostik adhesive for your EV battery pack manufacturing needs, you can also receive:

- Dedicated technical support: Our experts work with you to identify the right adhesive technology for your needs, assisting with testing and trials to keep your processes streamlined.

- Global supply security: As an Arkema company, we offer manufacturing and technical support resources across the world to help ensure your needs are met.

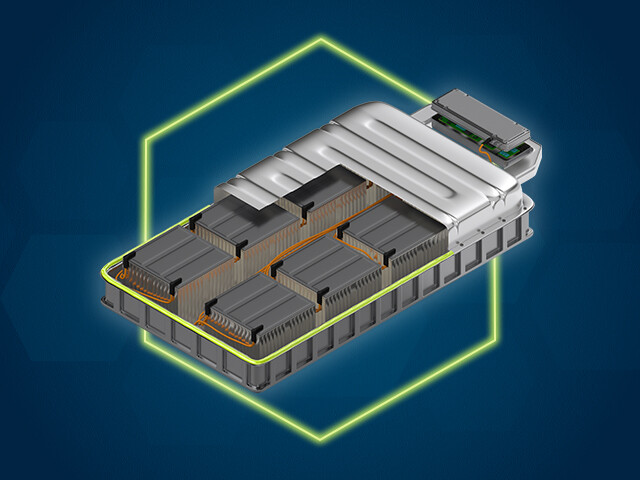

- Access to our broad portfolio: We provide adhesives for other EV battery applications, such as cell to pack, thermal management and more to help improve your performance, processing and sustainability across applications.

Why wait? Have a discovery call with our experts to see how our EV battery pack adhesives can help you.