Clarity and Strength: In-Line Labeling Adhesives for Glass Containers

Supporting Sustainability, Efficiency, and Your Brand

Industry Trends for Labels on Glass

Current labeling trends for glass are driven by sustainability, aesthetics, regulatory requirements, and technological advancements. Among them are:

- More sustainable adhesives. This includes water-based, biodegradable, and recyclable options compatible with the recyclability of glass containers.

- Recyclable labels. Adhesives that allow labels to be easily removed without leaving residue are increasingly popular. This aids in generating high-quality recycled glass.

- Transparent labels. The no-label look is appealing to many consumers and brands, as it allows the contents of the glass container to remain the focal point. Clear label materials, paired with the right adhesive, can blend perfectly with the glass.

- Premium finishes. Techniques like metallic accents and embossing can heighten visual appeal of the product and enhance consumer perception of both product and brand.

- Pressure-sensitive labels. Because they require no water or heat activation, labels using pressure sensitive adhesives can support faster production lines and may also allow lower energy usage.

- Removable label adhesives. Labels that can be easily removed boost the efficiency of glass recycling processes. They may also reduce energy and water usage.

5 Other Essentials for Your Glass Labeling Adhesive

1. Chemical Compatibility

Although it is a common conception that glass is relatively inert, this is not entirely so. Certain adhesives may contain components that can react with the glass over time, weaking the bond or causing discoloration. Choosing an adhesive specifically formulated for use with glass helps ensure reliable adhesion and long-term performance.

2. Strength and Durability

Sturdiness is one of the key features of glass containers. Over the course of their lives, from manufacturing and shipping to consumer use and beyond, they can take a great deal of abuse. The chosen adhesive must provide a strong, permanent bond despite minor bumps or drops. For products that may be subject to moisture or condensation, the adhesive should also be water-resistant to prevent degradation or peeling of the label.

3. Label Material Compatibility

In addition to being suited to glass, the adhesive must also adhere well with the label material. Glass containers can be paired with paper, foils, various plastics, and other specialty substrates. Your choice of label can narrow the list of glass-appropriate adhesives suitable for your product.

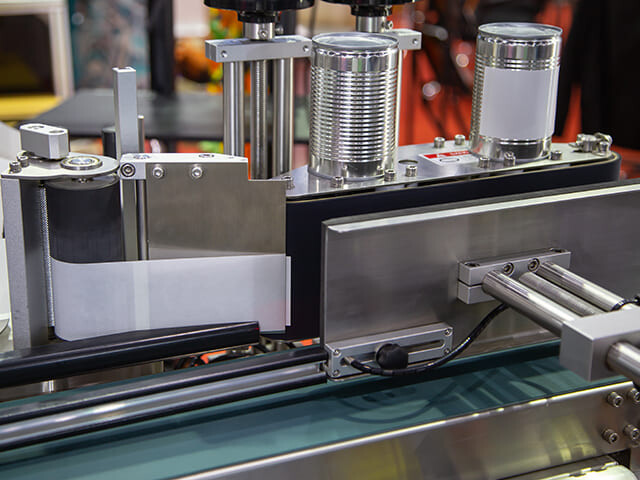

4. Production Considerations

Your application method also impacts adhesive selection. For high-volume production lines, fast-setting adhesives are typically chosen to support manufacturing process efficiency and to avoid label damage. The adhesive should also provide for clean and accurate application to reduce downtime for clean-up.

5. Support for Sustainability

In-line labeling for glass food packaging and other consumer goods containers can contribute to environmental concerns in several additional ways.

- Reduced water usage. Glass recycling is well-established, and certain adhesives are formulated to be easily removed during this process. Cleaner separation of the label from the glass can reduce the amount of water needed to wash away the label and residue.

- Energy efficiency. Because glass is regularly recycled, it already supports the circular economy. Choosing bio-based adhesives further offers environmental benefit minimizing reliance on energy-intensive process like fossil fuel extraction and processing.

- Compatibility with recycled label stock. Not all adhesives can bond well with highly recycled paper. Those that do offer extra benefit for circularity.

- Lightweighting. In-line labeling systems can precisely apply the required amount of adhesive. The right choice of glue also supports the use of thinner labels. Both help to minimize raw material usage and weight

Bostik Hot-Melt Labeling Adhesives for Glass

Our single global adhesive brand has a wide range of adhesive solutions. All are easy to use and enable the manufacture of reliable products through:

- High adhesive bond strength for all-around peace of mind

- Low odor for improved production and consumer satisfaction,

- High safety standard certifications supporting the most demanding of regulations

- Enhanced supply security for supply confidence

Our hot-melt solutions also support your manufacturing efficiencies through:

- Excellent compatibility with equipment and substrates for simple conversion

- Low-adhesive consumption with proven high add-on savings

- Clean running resulting in few line stops and high productivity

Lastly, they offer a host of environmental advantages, including:

- Suitable for use on the most challenging, renewable, or sustainable materials

- Excellent processability and bond performance resulting in low waste

- Low application temperatures and low consumption enabling energy reductions

- Renewable and compostable formulations to support you and your consumers’ sustainable ambitions

- Formulations meet European Union and United States paper recycling guidelines

Other Powerful Reasons to Partner With Bostik

When you choose Bostik as your adhesive supplier, you’ll also discover a host of advantages beyond the adhesive. These include:

- Knowledge, expertise, and innovation drawn from Bostik and Arkema teams across the globe. This enables us to tap into both new opportunities and regional insights to better meet your needs

- The resources we create to help you grow your adhesive and market knowledge, including webinars, training, whitepapers, blogs, and more

- Product support from our trained professionals, such as coater trials, product audits, and line audits

Let us enable and empower you to create, to do, to improve. Whatever challenge you are facing, we have or will find a solution, because we have the knowledge and experience you need to bring your products—and ideas—to the market.