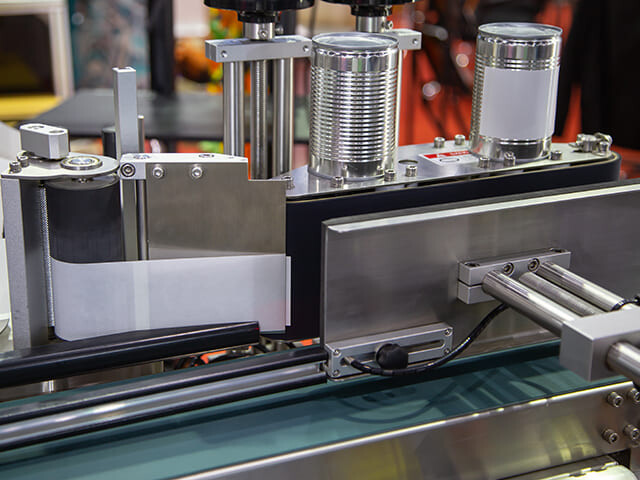

Streamlining Efficiency: High-Speed In-Line Labeling for Plastic Containers

Plastic-Compatible Adhesives for Product Labeling

Market Pressures Fuel In-Line Labels

Several factors are driving the adoption of in-line labeling within the consumer goods market:

- Rising consumer expectations for convenience and transparency through clear and accurate product information

- The need for faster production speeds to meet market demands

- Durable labeling solutions that can withstand the rigors of shipping and handling in the expanding ecommerce market

- Options for labeling consumer products that support plastics recycling and boost sustainability

In-line labeling allows for consistent and reliable application, ensuring product integrity throughout the supply chain.

Specific Needs for Plastic Containers

Choosing the right adhesive for your in-line labeling on plastic requires careful consideration of several factors. First among them is the need to form a strong, lasting bond to the plastic packaging or container surface. A few details to keep in mind:

- Surface energy. Plastics generally have a lower surface energy than glass or metal. To create a strong initial bond, these label adhesives need to provide a high degree of adhesion. This also helps to counter the effect of uneven surfaces, found on some plastic containers.

- Flexibility. Unlike glass or metal, plastic containers can bend and flex. Their adhesives should be supple enough to accommodate movement without cracking or peeling the label.

- Chemical resistance. Some plastics are more resistant to certain chemicals than are glass and metal. Polyethylene (PE) and polypropylene (PP) are common examples. Choose a labeling adhesive that is specifically formulated to avoid chemical reactions with these plastics, thus weakening the bond.

- Outgassing. Some plastic, especially some types of PVC, can outgas chemicals that could affect adhesive bonds. Choose hot melts created with these types of plastic in mind.

An incorrect adhesive selection can lead to poor adhesion or delamination. Both of these outcomes negatively impact sales and consumer satisfaction.

Technical In-Line Considerations

Regardless of container material, the adhesive should ensure that labels remain firmly affixed during production, transportation, storage, and use. It should also resist environmental conditions, including varying temperatures and moisture levels.

Choosing the right adhesive for in-line labeling also requires a look at certain technical considerations.

- Equipment compatibility. Appropriate pairing of an adhesive and your in-line labeling equipment helps ensure smooth processing.

- Precise application. The glue should apply only where intended, allow for easy cleanup and require minimal downtime for maintenance.

- Drying time. In high-speed production lines, rapid setting is essential to prevent labels from smearing or becoming mis-aligned as products move through the manufacturing process.

- Viscosity. A balanced viscosity supports smooth and consistent application during labeling. This helps minimize waste and optimize production efficiency.

Supporting Sustainability Initiatives

In-line labeling adhesives can enable environmental considerations in a few ways:

- Bio-based materials. Adhesive can be formulated using a higher degree of renewable resources, reducing reliance on petroleum-based content. This also helps to lower the carbon footprint of the adhesive.

- Reduced waste. In-line labeling systems are designed for efficiency, minimizing adhesive use and scrap generation. This addresses solid waste ending up in landfills.

- Improved recyclability. By adhering to plastics industry guidelines for labels in post-consumer recycling, adhesives can help to reduce plastic waste.

Bostik In-Line Labeling Solutions for Plastic

Our complete line of hot-melt adhesives meet these needs and more. With regards to production concerns, they offer:

- Low adhesive consumption with proven high add-on savings

- Clean running resulting in few line stops and high productivity

- Enhanced supply security for supply confidence

- High adhesive performance for all-around peace of mind

- High safety standard certifications supporting the most demanding of regulations.

Bostik’s hot melt adhesives also support environmental concerns:

- Suitable for use with the most challenging, renewable, or sustainable materials.

- Renewable and compostable formulations to support you and your consumers’ sustainable ambitions

- Low odor for improved production and consumer satisfaction

At Bostik, our goal is to empower you to create the products you imagine. Our hot melt adhesive technology delivers the comfort, environmental advantages, and operational efficiencies you need to enhance the lives of your consumers around the world. Whatever your adhesive need, we’ll help make it a reality.