EV Battery Thermal Management

On-demand webinar: Unlocking EV Battery Potential with Advanced Thermal Interface Materials (TIMs)

How Thermal Interface Materials (TIMs) Help EV Battery Packs?

Incorporating Thermal Interface Materials (TIMs) into your EV battery manufacturing is important to prolonging the overall battery life. When an EV battery is charging, discharging or in use, heat is generated inside. Lithium-ion (Li-ion) cells, which are a type of rechargeable battery commonly used for their high energy density and light weight, can degrade faster when exposed to high temperatures, resulting in a shorter lifespan. TIM conductivity, however, can transfer heat away from a battery cell to a heat sink or semiconductor device. This helps enable:

- Battery operating temperature: When the heat is properly transferred throughout the EV battery cells, you can more easily reach the desired battery operating temperature of 30°C to 40°C, which helps ensure stability and that the battery isn’t overheating. In particular, the battery cell temperature should never exceed 80°C, and battery charging or discharging temperatures should stay between 0°C and 60°C.

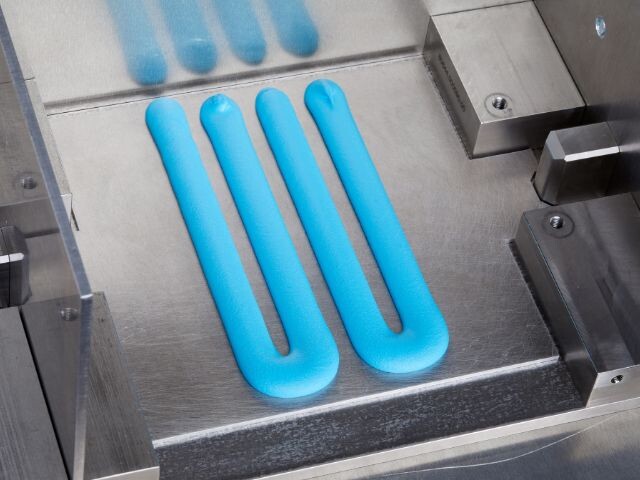

- Optimum battery performance: By filling air gaps and irregularities between two surfaces, such as the battery cells and a heat sink, TIM helps reduce thermal resistance and allows heat to flow more efficiently. With these imperfections filled, the TIM helps maintain a consistent temperature within the battery pack to help prevent overheating or degradation.

To enrich our portfolio in the battery industry, we acquired Polytec PT in 2023, specialized in thermal interface materials.