How to apply liquid damp proof membranes for concrete floors

What is a liquid DPM?

A liquid DPM (damp proof membrane) acts as a barrier to suppress residual moisture in a subfloor. It is also referred to as a moisture suppressant and is applied to a subfloor when the moisture levels are too high before the installation of a self-levelling compound.

A liquid DPM enables moisture to evaporate in a controlled way from the subfloor to reduce the risk of a flooring failure.

What does a liquid DPM protect against?

On older properties (pre-1970s) where no base damp proof membrane is present, damp can rise from the ground and make it through the concrete subfloor, which can then affect the self-levelling compound, adhesive and floor coverings above. This can be a big issue for modern floor coverings such as highly flexible vinyl, which do not tolerate moisture effectively, as well as wooden floors that are prone to warping.

New builds can be susceptible to moisture in the subfloor too, often due to inadequate time being allowed for a new screed to dry before floor coverings are laid, or residual moisture left behind by other trades working on the same project.

You can measure the amount of moisture in a subfloor with moisture testing equipment, such as a hygrometer. Floors with a relative humidity (RH) greater than 75% are at a large risk of failure if a liquid DPM is not used. Taking this risk leaves the flooring open to a plethora of problems that can cost installers significant time and expense to rectify.

You should always use a liquid DPM for concrete floors if there is dampness or you suspect there may be moisture in the subfloor.

Step-by-step: how to apply liquid dpm for concrete floors

For the best results, ensure the subfloor is clean and free from dust or any other contaminants.

- If skirting boards can’t be removed, protect them with masking tape.

- Shake the liquid DPM container well before use and pour the product into a mixing tray.

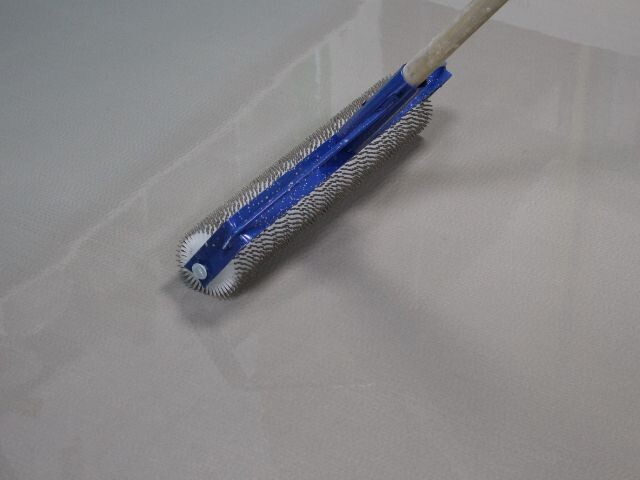

- Apply around the edge of the room using a paintbrush, and then use a pre-wetted short pile roller for the larger areas.

- A liquid DPM such as Bostik Cempolatex Moisture Suppressant must be applied in two coats. Apply the first coat in one direction, ensuring that the material is worked well into the substrate.

- Wait until the first coat of liquid DPM is touch-dry - approximately 15 to 30 minutes at 20°C – before applying the second coat at right angles to the first coat.

It is essential that a pinhole free coating is achieved and you should maintain a coverage rate of 20m2 per 2.5L per coat, i.e. a 5L unit should cover 20m2 at two coats.

What key benefits should you look for in a DPM?

Time is often a high priority for flooring projects, so when choosing the best liquid DPM for your project, you should look to rapid drying products, like Bostik’s Cempolatex Moisture Suppressant. These offer a drying time of approximately one hour and enable fast access to the area, minimising downtime.

You can make sure you have comprehensively covered the subfloor by choosing a coloured liquid DPM. These products enable you to see what area you have already coated before drying to a different colour.

Two-component DPMs require you to mix the two parts together and, as they are formulated specifically for the quantities in each container, you need to use all of the product at once. One advantage of some single-component moisture suppressants is the ability to reseal and reuse the product. This is especially useful if you are carrying out flooring installations on relatively small areas and don’t need a lot of product.

Everything you need to know when applying liquid DPM

Now that we’ve explained the benefits of using a liquid DPM for concrete floors, here we take a look at some of the frequently asked questions when it comes to applying a liquid DPM.

At 20°C, the drying time for the first coat of liquid DPM will be approximately 15 to 30 minutes.

When applied in the same conditions, the second coat should also dry within 30 minutes.

Tip: You should ensure the liquid DPM is kept free of foot traffic and is allowed to dry to a tack-free film before moving onto the next stage of the installation.

Yes you can. For a fast-track installation that allows you to install new floor coverings in as little as 4 hours, we offer the following system:

Bostik Cempolatex Moisture Suppressant

A ready-to-use, water based, single part surface membrane for cementitious floors. Two coats will provide protection up to 95% RH and the container is resealable and reusable.

Bostik Cempolay Universal Primer

A water-based, solvent-free, acrylic dispersion floor primer and bonding agent that’s suitable for use prior to the application of any Bostik self-levelling compound.

When applied undiluted, it acts as a bonding agent on non-porous surfaces such as power floated concrete, ceramic tiles, quarry tiles, rigid metal, terrazzo, asphalt and surface membranes. In diluted form, Bostik Cempolay Universal Primer can be used as a primer on porous surfaces and will dry within one hour depending on the conditions.

Bostik Cempolatex Rapid 30

A high strength, quick-drying self-levelling compound with a walk on time of just 30 minutes. It will smooth sound, uneven surfaces prior to the laying of decorative floor coverings. It is also suitable for use with underfloor heating. Accepts loose lay floor coverings and bonded tiles from 45 minutes, accepts other bonded floor coverings from 3 hours.

Watch our video for our top tips for a fast-track flooring installation.

Base damp proof membranes, or sheet DPMs, are a membrane material applied under a concrete slab to prevent moisture transmission. They’re installed during the construction of a building, although they are not always present in older buildings, especially those built before 1970.

A liquid DPM can be applied over an existing concrete floor to suppress residual moisture, and should be used in floors with more than 75% RH before installing new floor coverings.

Bostik Cempolatex Moisture Suppressant

A ready-to-use, water based, single part surface membrane for cementitious floors. Two coats will provide protection up to 95% RH and the container is resealable and reusable.

Liquid damp proof membranes provide reliable moisture protection when applied correctly to concrete and sand/cement screed (to a maximum hygrometer reading of 95% RH) floors. Their excellent adhesion creates a seamless barrier that prevents moisture from affecting floor coverings above.

For optimal performance, surface preparation is crucial. A clean, contaminant-free concrete surface ensures the membrane bonds properly and delivers long-lasting protection. The low-odour formulation makes them particularly suitable for indoor applications.

Professional contractors value liquid DPMs for their versatility and ease of application. A properly installed membrane effectively controls moisture migration through the concrete, protecting your floor coverings and maintaining their integrity over time.

Residual moisture readings above 65%RH for wood, and 75%RH for resilient floor coverings in concrete subfloors, signal the need for a liquid DPM application.

Before tiling, installing wood flooring, or laying vinyl coverings, check your subfloor's moisture content. Pay special attention to newly laid concrete floors, as these require proper moisture suppression to prevent future floor covering failures.

The presence of dark patches on your concrete floor or a musty odour often indicates rising damp issues that need addressing with a liquid DPM.