EV Battery Thermal Interface Materials

On-demand webinar:

Unlocking EV Battery Potential with Advanced Thermal Interface Materials (TIMs)

How Thermal Interface Materials (TIMs) Help EV Battery Packs?

Incorporating Thermal Interface Materials (TIMs) into your EV battery manufacturing is important to prolonging the overall battery life. When an EV battery is charging, discharging or in use, heat is generated inside. Lithium-ion (Li-ion) cells, which are a type of rechargeable battery commonly used for their high energy density and light weight, can degrade faster when exposed to high temperatures, resulting in a shorter lifespan. TIM conductivity, however, can transfer heat away from a battery cell to a heat sink or semiconductor device.

This helps enable:

- Battery operating temperature: When the heat is properly transferred throughout the EV battery cells, you can more easily reach the desired battery operating temperature of 30°C to 40°C, which helps ensure stability and that the battery isn’t overheating. In particular, the battery cell temperature should never exceed 80°C, and battery charging or discharging temperatures should stay between 0°C and 60°C.

- Optimum battery performance: By filling air gaps and irregularities between two surfaces, such as the battery cells and a heat sink, TIM helps reduce thermal resistance and allows heat to flow more efficiently. With these imperfections filled, the TIM helps maintain a consistent temperature within the battery pack to help prevent overheating or degradation.

To enrich our portfolio in the battery industry, we acquired Polytec PT in 2023, specialized in thermal interface materials.

Best EV Battery Thermal Interface Materials

Electric vehicle (EV) battery systems require high-performance thermal interface materials (TIMs) to manage heat dissipation and ensure efficiency. These materials help transfer heat away from battery cells, preventing overheating and extending battery life.

Bostik's Advanced Thermal Interface Materials

Bostik offers cutting-edge TIM solutions designed to optimize EV battery performance. Their thermal management technologies focus on:

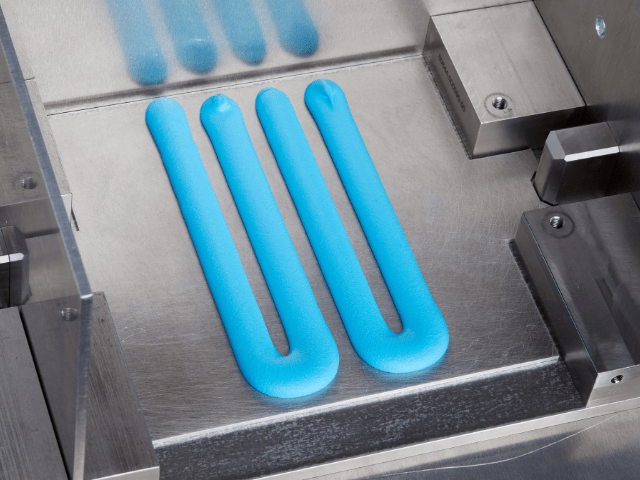

- Thermally Conductive Gap Fillers: Soft, compressible materials that conform to uneven surfaces, reducing thermal resistance and enhancing heat dissipation.

- Thermally Conductive Adhesives: Used to bond components while facilitating efficient heat transfer.

- Silicone-Free Thermal Pastes: Low-density, non-abrasive solutions that improve battery longevity.

EV battery thermal interface materials list

| TIM Type | Function | Key Features |

|---|---|---|

| Thermally Conductive Gap Fillers | Fill air gaps and improve heat dissipation | High thermal conductivity, flexible application |

| Thermally Conductive Adhesives | Provide bonding while ensuring efficient thermal transfer | Strong adhesion, optimized heat management |

| Silicone-Free Thermal Pastes | Enhance heat dissipation without abrasion | Low-density, non-abrasive, easy application |

| Thermally Conductive Pottings | Protect and insulate battery modules | High dielectric strength, aluminum compatibility |

| Customizable TIM Solutions | Tailored for specific EV battery applications | Adaptable formulations, optimized performance |

Bostik’s advanced TIMs, including Polytec PT products, support battery performance, longevity, and safety in electric and hybrid vehicles.

EV Battery Thermal Interface Material Market: Advanced Solutions by Bostik

As the demand for electric vehicles (EVs) continues to grow, efficient thermal management has become a critical factor in ensuring battery performance, safety, and longevity. Bostik, a leader in adhesive and sealant technologies, offers advanced thermal interface materials (TIMs) designed to optimize heat dissipation and enhance battery reliability.

The Importance of Thermal Interface Materials (TIMs) in EV Batteries

EV batteries generate significant heat during charging, discharging, and operation. Without proper thermal management, excessive heat can lead to:

- Reduced battery efficiency and performance degradation.

- Shortened battery lifespan due to thermal stress.

- Safety risks, including overheating and potential thermal runaway.

TIMs play a crucial role in transferring heat away from battery cells, ensuring optimal operating temperatures and preventing performance loss.

Bostik’s Advanced TIM Solutions

Bostik provides cutting-edge thermal interface materials tailored for EV battery applications. These solutions include:

- Thermally Conductive Gap Fillers: Designed to fill air gaps between battery cells and cooling elements, ensuring efficient heat transfer.

- Thermally Conductive Adhesives (TCAs): Offering high mechanical strength while maintaining thermal conductivity, ideal for battery pack assemblies.

- Phase-Change TIMs: Enhancing heat dissipation during fast-charging cycles, preventing overheating.

- Silicone-Based TIMs: Providing long-term stability and high thermal conductivity, ensuring consistent battery performance.

Key Benefits of Bostik’s TIM Solutions

- Enhanced Battery Safety: Prevents overheating and ensures stable temperature regulation.

- Improved Battery Longevity: Reduces thermal stress, extending battery life.

- Optimized Performance: Maintains efficient energy transfer, supporting fast-charging capabilities.

- Regulatory Compliance: Meets industry standards for EV battery thermal management.

Industry Trends Driving TIM Adoption

The EV battery market is evolving rapidly, with key trends influencing TIM development:

- Fast-Charging Infrastructure: High-powered charging stations require advanced TIMs to manage increased heat loads.

- High-Energy Density Batteries: Next-generation battery designs demand efficient thermal solutions to prevent overheating.

- Sustainability Initiatives: Manufacturers are prioritizing eco-friendly TIMs with low environmental impact.

Bostik’s Commitment to Innovation

Bostik continues to lead the charge in EV battery thermal management, collaborating with Polytec PT to develop next-generation TIM solutions2. Their expertise in thermal conductive adhesives ensures high-performance bonding and efficient heat dissipation for modern EV battery designs.

Battery Cooling Design

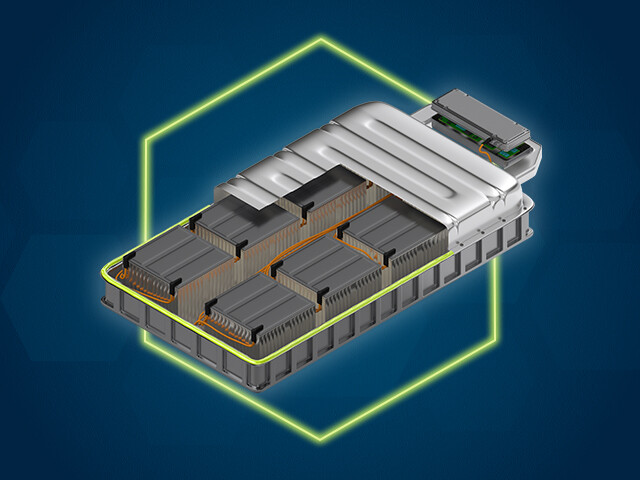

Effective battery cooling design is essential for maintaining optimal temperatures, enhancing performance, and ensuring battery longevity in electric vehicles (EVs). Proper thermal management prevents overheating, reduces degradation, and supports fast-charging capabilities.

Bostik’s thermal interface materials (TIMs) play a vital role in battery cooling systems, facilitating efficient heat dissipation through:

- Thermally Conductive Gap Fillers: Ensuring effective heat transfer between battery cells and cooling components.

- Phase-Change Materials: Adapting to temperature fluctuations, maximizing thermal efficiency.

-

Silicone-Based TIMs: Offering long-term stability for consistent cooling performance.

Frequently Asked Questions

EV battery thermal interface materials (TIMs) are designed to enhance heat transfer and prevent overheating in battery systems.

Electric vehicle (EV) batteries rely on a mix of critical and supporting materials that determine their performance, cost, and sustainability. Here's a breakdown of the key components:

Lithium

- Function: Enables energy storage and discharge in lithium-ion batteries.

- Source: Extracted from salt flats and hard rock mines, mainly in Chile, Argentina, and Australia.

- Challenge: Water-intensive extraction and environmental concerns.

Cobalt

- Function: Stabilizes battery chemistry and prevents overheating.

- Source: Predominantly mined in the Democratic Republic of Congo.

- Challenge: Ethical issues including child labor and supply chain transparency.

Nickel

- Function: Boosts energy density for longer driving range.

- Source: Found in Indonesia, Canada, and Russia.

- Trend: Shift toward high-nickel chemistries (NMC/NCA) to reduce cobalt use2.

Manganese

- Function: Adds structural stability and extends battery life.

- Source: Commonly mined in South Africa and Australia.

- Advantage : Less controversial than cobalt

| Component | Function |

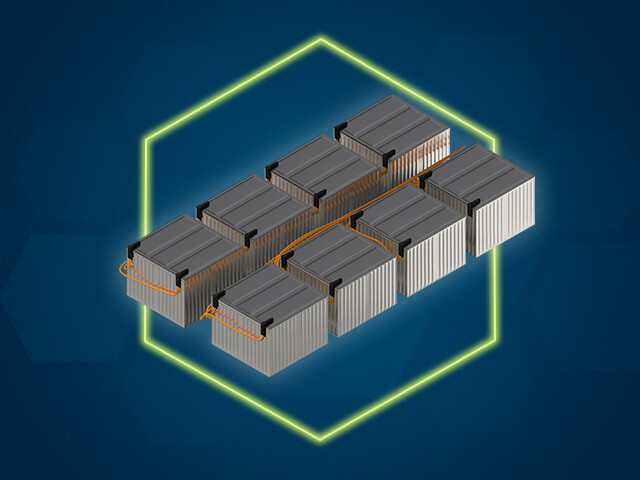

| Cells | The smallest energy storage units; contain electrodes and electrolyte. |

| Modules | Groups of cells bundled together for easier management and cooling. |

| Battery Pack | Assembled modules with casing, cooling, and control systems. |

Inside Each Battery Cell

Cathode (Positive Electrode)

- Made from lithium compounds mixed with metals like cobalt, nickel, manganese, or iron phosphate.

- Determines energy density, cost, and thermal stability.

Anode (Negative Electrode)

- Typically, graphite, sometimes blended with silicon for higher capacity.

- Stores lithium ions during charging.

Electrolyte

- Liquid or solid medium that allows lithium ions to move between electrodes.

- Usually, a lithium salt dissolved in organic solvents.

Separator

- A porous membrane that keeps anode and cathode apart while allowing ion flow.

- Critical for safety—prevents short circuits.