Oct 10, 2018 - 10 min

RESOLVE CASE AND CARTON HOT MELT ADHESIVE PRE-SET AND SLOW SET ISSUES

Hot melt adhesives are used in a range of markets, such as packaging, tape and label and product assembly. Offering fast processing, environmental friendliness and versatility, they are a common go-to choice for bonding.

However, hot melts are also prone to certain problems. In recent blogs, we discussed how to troubleshoot certain common hot melt adhesive and equipment problems, such as charring and stringing. We also looked at how to reduce the likelihood of packaging pop-opens.

Now, let’s take a look at what causes pre-set and slow set hot melt adhesive issues in case and carton packaging applications and what can be done to resolve them.

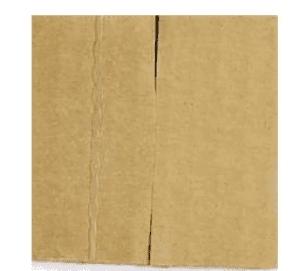

Case and Carton Hot Melt Adhesive Pre-Set

When a hot melt adhesive is compressed to a substrate, it forms a bond. However, the adhesive sometimes can set before the two materials are joined.

What Causes Adhesive Pre-Set?

There are several ways hot melt adhesive pre-set can happen. These include:

- Too low of an application temperature

- Not enough adhesive is applied

- Cold substrates causing the adhesive to set up too quickly

How Can Adhesive Pre-Set be Resolved?

- Increase the application temperature

- Increase the air pressure to apply more adhesive

- Preheat or condition the substrate prior to use

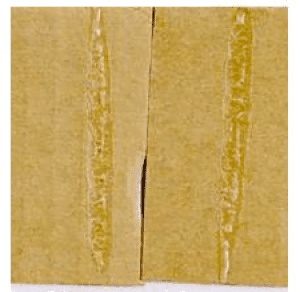

Case and Carton Hot Melt Adhesive Slow Set

Adhesive slow set relates to the length of time it takes for a hot melt adhesive to set. When an adhesive does not set properly, it can cause issues in the production line and adhesive failure.

What Causes Adhesive Slow Set?

The following issues can cause adhesive slow set:

- Compression time is shorter than required for the adhesive selection

- Compression may have been disturbed

- Too much adhesive is applied

- Application temperature is too high

How Can Adhesive Slow Set be Resolved?

- Check compression process

- Decrease application amount

- Decrease temperature

For more information on hot melt adhesive best practices and other industry news, sign up for our email list.