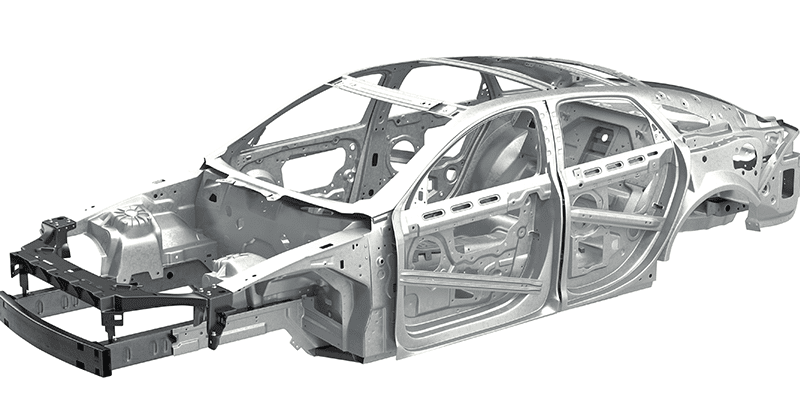

With lightweighting trends changing the body-in-white market, it’s a good idea to consider what these changes mean for body-in-white bonding. Take a look at key elements your bonding solutions should offer to meet consumer preferences and improve vehicle performance overall.

Material Compatibility

As lightweight materials, such as fiber-reinforced plastics, aluminum and magnesium alloy, replace conventional metallic materials, it’s important to ensure they’re bonded together with compatible adhesives.

For example, rubber-based adhesive technology, like elastosol, is specifically designed for lightweight body-in-white bonding applications. It also increases the ability to reduce number of welding points, improving both vehicle aesthetics and durability.

Environmental Friendliness

Another aspect to consider is the bonding solution’s environmental friendliness. Products that are solvent-free and non-flammable help improve your sustainability efforts. Additionally, worker safety is improved if the products yield no corrosive or toxic fumes when welding.

Product Quality

A body-in-white bonding solution should also enhance vehicle quality overall by offering:

- Corrosion protection

- Aging performance

- Consistent application

Furthermore, a long product shelf life can reduce overall costs and ensure product viability. In addition to this feature, elastosol bonding technology enables limited in-line equipment adjustments, which further lowers cost.

Process Efficiency

It’s also a good idea to think about how your body-in-white bonding solution will impact your overall assembly line processes. For example, a solution that offers the following capabilities will keep your production lines moving:

- Good wash-out resistance

- Fewer weld points needed

- Weld-through compatibility

--

Bostik manufactures smart body-in-white bonding solutions designed to improve assembly processes and vehicles overall. View this brochure to learn about a smart body-in-white bonding solution for anti-flutter, hem-flange, weld bonding and weld through sealing applications. You can also use the production selection chart to guide you through your decision-making process. Contact a Bostik expert for more assistance.