Aug 5, 2020 - 10 min

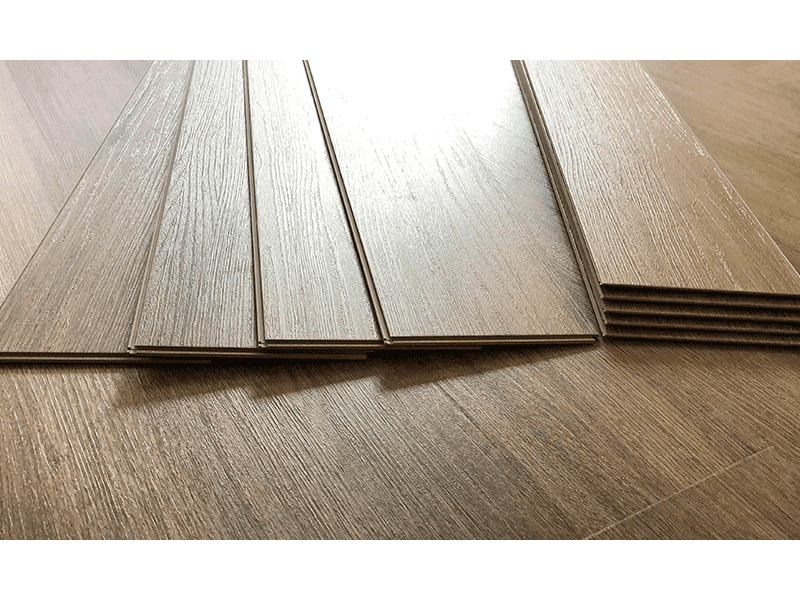

Are Your Resilient Flooring Adhesives Up to Par?

As the resilient flooring market skyrockets, due to expanding infrastructure development and governmental regulations on flooring materials, it’s important for manufacturers to ensure their resilient flooring adhesives are able to meet these demands.

Do Your Resilient Flooring Adhesives Bond to Low Surface Energy Substrates?

As flooring materials change, it’s a good idea to ensure your adhesives are formulated to bond to even the most challenging surfaces, like low surface energy substrates. Low surface energy substrates offer manufacturing benefits, such as

- Cost effectiveness

- Moisture and heat resistance

- Flexibility and durability

These types of substrates are typically:

- Polypropylene

- Polyethylene

- Teflon

- Other thermoplastic polyolefins

However, they are typically hard to bond to with traditional adhesives. This is because the adhesives are unable to sufficiently “wet out” the surface and form a strong bond.

Ensure your resilient flooring adhesives are able to bond to low surface energy substrates. This will allow you to keep flooring material options open as the market evolves.

Do Your Resilient Flooring Adhesives Offer Plasticizer Resistance?

Additionally, it’s important to ensure your adhesives offer sufficient resistance to plasticizer migration. Plasticizer migration is one of the leading compatibility problems with flooring. Often, plasticizers are added to flooring as a flexing agent. This enables the flooring to be more flexible and not brittle.

However, this can lead to plasticizer migration when substances in the material react with the adhesive. Plasticizer migration can cause flooring tiles to:

- Discolor

- Soften

- Slide around

Resilient flooring adhesives that offer plasticizer migration ensures that flooring is able to maintain its aesthetics and performance characteristics.

Do Your Resilient Flooring Adhesives Add Value During and After Installation?

Further, when choosing resilient flooring adhesives for floor assembly, consider how adhesives will be used during the installation process. For example, adhesives that offer peel and stick properties help improve efficiencies. By imparting anti-skid and sound damping capabilities, they can further improve overall floor performance, aesthetics and durability.

--

Interested in learning about what resilient flooring adhesives are right for you? Contact a Bostik expert today! You can also view this relevant content: