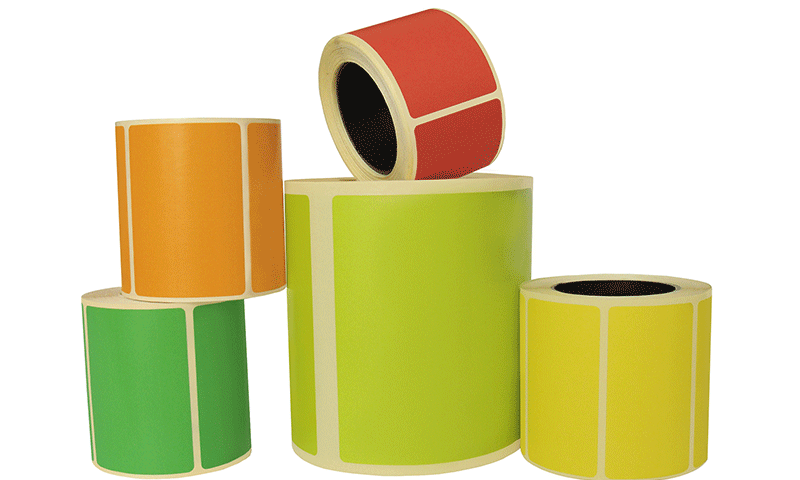

While the release liner is an important part of label construction, the chosen pressure sensitive adhesive (PSA) largely determines its performance capabilities. Find out three things to consider to ensure your release liner performance is an optimal level.

Consider End-Use Performance Requirements

Prior to manufacturing a label with its release liner and PSA, consider the end-use application's performance requirements. For example, the following items can dictate which PSA is chosen:- Temperature

- Bond strength

- Surface

- Product longevity

Know the Formulations

Additionally, it's a good idea to think about how the specific formulations can impact performance. PSA formulations typically consist of the following components:- Rubber elastomers

- Tackifying resins

- Antioxidants

- Process oils

The level of each component varies based on a given formulation. Percentage changes in formulations may impact how well a release liner is able to perform. Ensure your chosen PSA has a formulation optimal for your release liner. Think About Adhesive Coat Weight Choosing the right adhesive coat weight can also help optimize release liner performance. Prior to coating the adhesive onto the release liner, consider the following:

- Desired coating thickness

- Adhesive viscosity

- Required coating line speed

- Release liner material and surface characteristics

- Type of coating needed: direct or transfer