Mar 14, 2025 - 3-5 minutes

How Adhesives Help You Exceed Performance and Sustainability Goals

Bio-based adhesives have been around for years, but misconceptions remain. Are they: Safe? Effective? Good for the environment? Catch up on findings presented by Bostik’s Christophe Morel-Fourrier at RISE24 regarding plant-based adhesives and their advantages over fossil-based alternatives.

Facts and Misconceptions About Bio-Based Materials

Why Bio-Based Adhesives?

Many cultures have used bio-based adhesives for years. Rice starch glue has served since ancient times for arts and crafts, woodworking, and paper glue. Another example is based on casein, a milk protein, mixed with water and alkalis.

Why were bio-based adhesives used? Reasons vary, and can include:

- In ancient times, no other options were available

- Mimicry: attempts to replicate what is seen in nature

- Sometimes, they were just better than the available alternatives

In more recent years, adhesives have been created using fossil-based resources. They have often been considered less expensive, more effective, and have been seen to offer other advantages. But the recent revitalization in the industry toward more sustainable options has led to questions about bio-based solutions.

A Few Truths About Bio-Based Ingredients

There are common misconceptions in certain circles around bio-based adhesive solutions. In many cases, they are assumed to be safe, cheap, “good enough,” and better for the environment.

But here’s the truth: Compared to fossil-based equivalents,

- Natural does not necessarily mean safe

- Bio-based materials are not necessarily cheap

- They may not be good enough for certain purposes

- Depending on harvesting and processing, they may not be better for the environment

This is why it is necessary to review the benefits of any given adhesive technology, including assessing its long-term impact on sustainability.

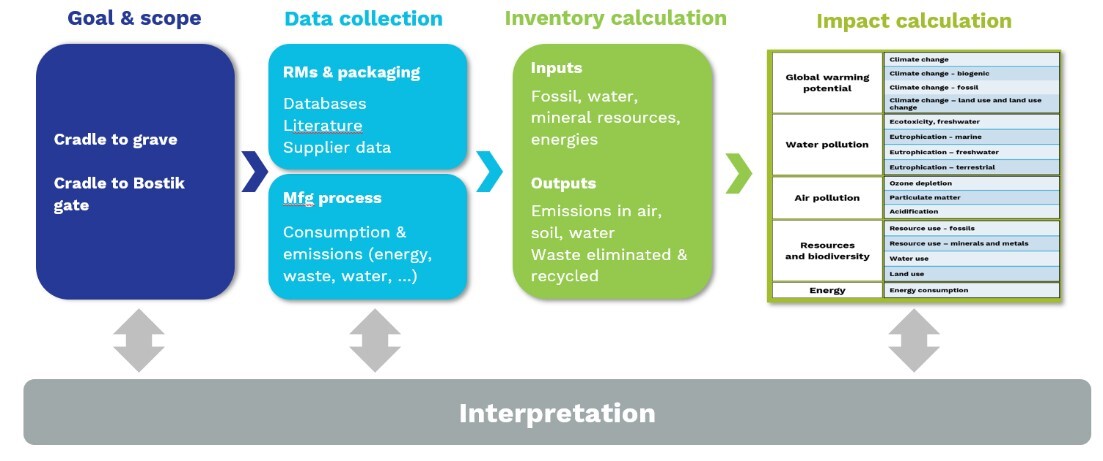

How to Determine What Is Good for the Environment

One well-established and trusted tool for determining a product’s environmental impact, which includes carbon footprint, is the Life Cycle Assessment (LCA) methodology. A variety of factors must be considered before determining which options are better for the environment. These include the impacts of raw materials, sourcing, processing, water and energy use, carbon emissions, and even transportation.

When using bio-based materials, some standards in LCA calculation will consider that the embedded carbon in the bio-based material, which is “biogenic,” coming from the conversion of CO2 by the plant, can be deducted, and is therefore considered a positive. This is the biogenic carbon uptake benefit, which will typically provide an advantage to bio-based materials, with a lower carbon footprint.

A Success Story: Castor Oil and PA11

One model example of a bio-based material that can help replace crude oil-based technology is derived from the castor bean. It has several qualities that make it a prime candidate for sustainable use. The castor bean:

- Is renewable

- Is not in direct competition with food

- Does not induce deforestation

- Grows in marginal soils

- Takes advantage of India’s natural rainy season

- Is profitable and easy for farmers to trade

These factors, along with a careful yet elaborate social program, help to make sure that on top of a lower carbon footprint, it is also sustainable from an environmental and social point of view.

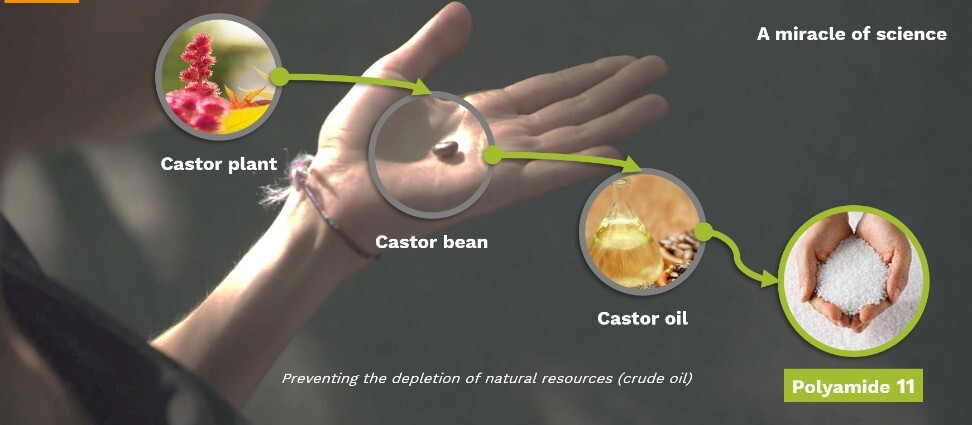

From the Castor Bean to Advanced Polymers

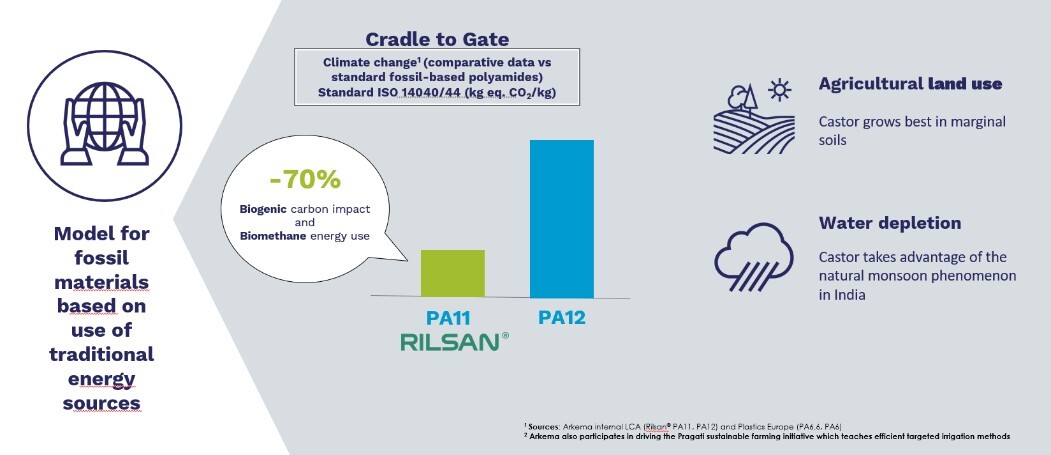

Castor oil, (which is mostly ricinoleic acid, a C18 fatty acid), is extracted from the beans. It is the raw material that Arkema converts through exclusive processes into a C11 acid and a C7 alcohol. The C11 acid is polymerized to provide polyamide 11, a unique structure, where the typical petroleum-based alternative is C12. Our PA11, sold under trade name Rilsan®, has outstanding cradle to gate environmental performance1, with a carbon footprint that is down 70% compared to PA12 (when considering biogenic carbon uptake benefit and the fact that our facility was converted to biomethane energy use.)

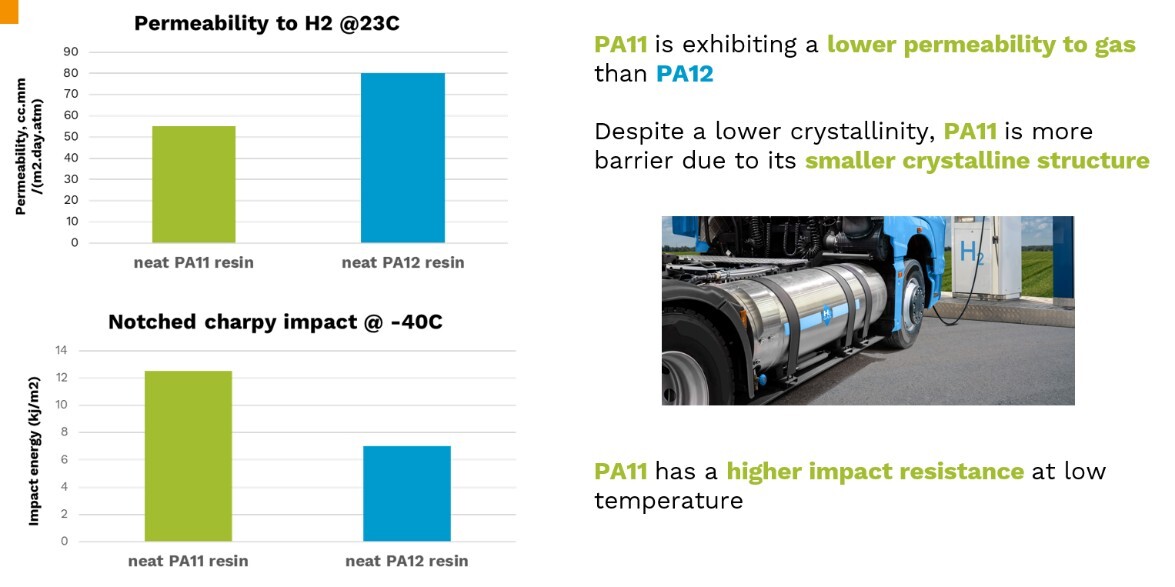

Besides an excellent environmental performance, PA11 has distinct properties compared to PA12, in particular due to its crystalline structure.

The Benefits of Co-Polyamides

These materials make very good adhesives for:

- Filter assembly

- Flexible vinyl bonding

- Wood bonding

- Fabrics bonding

And demonstrate excellent properties, including:

- Adhesion

- High-temperature performance

- Chemical and plasticizer resistance

In the choice of monomers, when moving from regular short chain acid to fatty acid, we discover that …

Long-chain hydrocarbon segments offer:

- Flexibility

- Substrate wetting

- Melting point control (vs. nylons)

- Low-energy substrate adhesion

While the amide groups provide:

- High intermolecular cohesive strength

- High melting point and green strength

- Adhesion to polar substrates

From Castor Oil Comes a New Cyanoacrylate Adhesive

This adhesive technology, when using a monomer derived from castor oil, has very desirable benefits:

- Non-irritant, with a natural odor of lime

- No blooming

- Very good tensile strength

- Very good reactivity

- Very high water resistance (and dishwasher safe)

Bio-Based Materials Help Support a Circular Economy

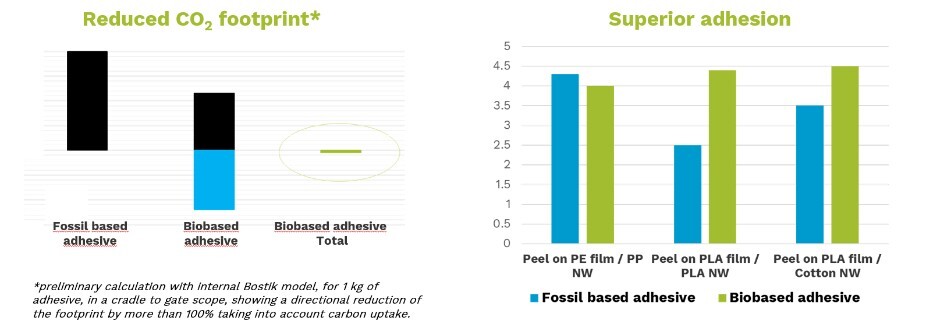

The use of natural resins in hot melts shows a carbon footprint reduction greater than 100%. But that’s not all. Adhesion testing reveals superior adhesion on natural substrates such as cotton, and bio-based materials such as PLA. Moreover, its peel performance is nearly identical to the fossil-based alternative.

But more interestingly, the bio-based adhesive also enables debonding of PE (polyethylene) film and PP (polypropylene) nonwovens under specific conditions. This allows for the recovery of higher quality plastic after recycling.

Sustainable New Technologies … From Bostik and Arkema

By exploring cost-effective bio-based materials and opportunities such as castor oil or natural resins, the experts at Bostik and Arkema are working to reduce environmental impacts while providing desirable technical features, thus implementing sustainable new technologies. It is our expectation that these materials will deliver the attributes you need to exceed both your performance and sustainability goals.

1 Source: Information Sources, Inc, Multi Outlet + Conv; Plains Region; Latest 52 Weeks Ending 05-15-22.

©2025 Bostik, Inc. All Rights Reserved

All information contained herein is believed to be accurate as of the date of publication, is provided “as-is” and is subject to change without notice. To review our full U.S. Legal Disclaimer, visit: https://bostik.com/us/en_US/legal-disclaimer