Dec 9, 2022 - 3-5 minutes

How to Eliminate Cylindrical Assembly Mechanical Problems

Learn how retaining compounds allow you to extend the lifespan of your cylindrical assembly, no matter the type of fitting you’re utilizing.

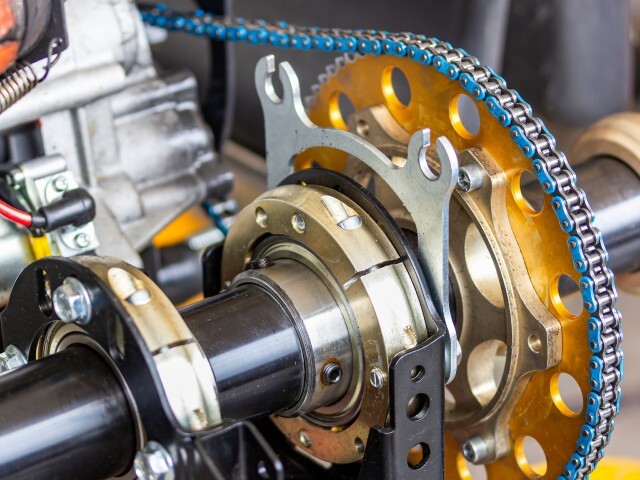

In the MRO industry, you know it’s critical for a cylindrical assembly to provide top end-use performance to ensure seamless, long-lasting machinery operations. However, equipment failures involving bearings and shafts within the assembly can quickly lead to:

- Reduced production efficiencies

- Increased equipment costs and production needs

- Decreased ability to reach high performance levels

Challenge #1: Cylindrical Assembly’s Bearings and Shafts Impact Production Efficiencies

Fretting is a common problem that can occur and negatively impact production in addition to reducing the overall bearing and shaft lifespan. It can happen when a fitting only has 30% metal to metal contact, allowing air, chemicals or moisture to get into small gaps or crevices between the bearings and shafts. Eventually, these elements cause it to become more difficult to pull the bearing and shaft apart if it needs to be disassembled. Often mechanics will cut the bearing and shaft off entirely, which can result in more downtime and maintenance costs to fix it.

Solution:

Retaining compounds offer fretting protection by providing a unitizing seal, blocking out air, chemicals or moisture. This protection also helps with:

Maximum load distribution: Retaining compounds create 100% contact, filling voids or imperfections that could cause fretting over time between the bearing and shaft. The diagram below shows how retaining compounds create a bond between the bearing and shaft, providing the necessary strength for uniform stress distribution so the load is evenly dispersed over the joint.

Solution:

Retaining compounds offer fretting protection by providing a unitizing seal, blocking out air, chemicals or moisture. This protection also helps with:

Maximum load distribution: Retaining compounds create 100% contact, filling voids or imperfections that could cause fretting over time between the bearing and shaft. The diagram below shows how retaining compounds create a bond between the bearing and shaft, providing the necessary strength for uniform stress distribution so the load is evenly dispersed over the joint.

Prolonged equipment life: Retaining compounds prevent deterioration before it begins. This eliminates the need to cut off a bearing due to fretting, given that retaining compounds protect the gaps and crevices where deterioration occurs. Without the worry of fretting causing your cylindrical fit to wear down, you can rely on the same bearings and shafts for a long period of time. Further, retaining compounds will make it easier to separate a bearing and shaft if it does need to be disassembled, once again preventing the need to cut the pieces apart.

Challenge #2: Cylindrical Assembly’s Bearings and Shafts Increase Equipment Cost and Production Needs

While your choices in cylindrical fits can vary, they can all become a costly part of your overall assembly. For example, press and shrink fits can easily provide precise assemblies, but these options may be costly due to the equipment requirements and production time it can take to get the sizing just right. While slip fits are more cost effective, this option may not protect a bearing or shaft from fretting if there are any gaps, leading to potential repair costs.

Solution:

As a liquid bonding component, one bottle of retaining compounds can offer the same bonding strength you may find with numerous mechanical fasteners or other components, replacing your stock of replacement parts. Retaining compounds can be easily incorporated into slip fits to protect against gaps, enabling in-house maintenance workers to machine a slip fit themselves to gain the same strength levels you’d have with a press fit. This eliminates the need to send your slip fit machinery to a company to get the same performance strength, saving you valuable production time and repair costs. Further, you can also add retaining compounds to a press fit, helping your machinist shape a shaft at a faster rate than it would without the retaining compound. This helps reduce operations that could otherwise become costly for overall production time.

Solution:

As a liquid bonding component, one bottle of retaining compounds can offer the same bonding strength you may find with numerous mechanical fasteners or other components, replacing your stock of replacement parts. Retaining compounds can be easily incorporated into slip fits to protect against gaps, enabling in-house maintenance workers to machine a slip fit themselves to gain the same strength levels you’d have with a press fit. This eliminates the need to send your slip fit machinery to a company to get the same performance strength, saving you valuable production time and repair costs. Further, you can also add retaining compounds to a press fit, helping your machinist shape a shaft at a faster rate than it would without the retaining compound. This helps reduce operations that could otherwise become costly for overall production time.

Challenge #3: Reaching High Performance Levels with Your Cylindrical Assembly

If you are currently using retaining compounds for cylindrical assembly, it’s quite possible you are only using one variation to help your bearings and shafts to work efficiently. This is a common occurrence as many mechanics rely on one product they’ve used for a long time. However, a single option may not be the best solution for all crevices you’re trying to fill, specifically if your fitting has large gaps that need high strength levels.

Solution:

Retaining compounds are available in various viscosity levels in relation to cylindrical assembly and strengths. Choosing the right viscosity level will improve the bonding strength needed to create 100% metal contact in the bearing and shaft to prolong usage without wear and tear. It’s best to choose the viscosity level according to the specific needs of your equipment:

Solution:

Retaining compounds are available in various viscosity levels in relation to cylindrical assembly and strengths. Choosing the right viscosity level will improve the bonding strength needed to create 100% metal contact in the bearing and shaft to prolong usage without wear and tear. It’s best to choose the viscosity level according to the specific needs of your equipment:

- Low viscosity retaining compounds can easily fit into smaller gap fills, as they have an oil-like consistency. This bonding strength is common for filling tight gaps in press fits.

- Medium viscosity retaining compounds offer high strength to prevent leakage and vibration. Since its consistency is thicker than a low viscosity strength, medium viscosity retaining compounds are often used to fill medium-sized gaps in slip fits.

- High viscosity retaining compounds are useful to fill larger gaps, specifically for cylindrical assemblies that have not been formed for a tighter fit. With a paste consistency, this viscosity level is useful for a badly worn shaft or bearing.

How Bostik Can Help Overcome Cylindrical Assembly Challenges with Retaining Compounds

Whether you’re looking to improve efficiencies, lower costs or reach high performance with your cylindrical assembly, Bostik’s Born2Bond™ anaerobic retaining compounds provide the right solutions for your mechanical needs. These single-component bonding technologies seal all metal joints and protect gaps to eliminate fretting, providing 100% surface to surface contact. These features allow for a strong bond to:

Are you ready to learn how retaining compounds can help you overcome challenges with cylindrical assembly? Contact a Bostik representative to learn about the available solutions with retaining compounds.

To learn how our retaining compounds meet a range of performance grades, click here.

Learn More

- Withstand vibration

- Resist extreme temperatures

- Protect against chemical substances

Are you ready to learn how retaining compounds can help you overcome challenges with cylindrical assembly? Contact a Bostik representative to learn about the available solutions with retaining compounds.

To learn how our retaining compounds meet a range of performance grades, click here.

Learn More

©2023 Bostik, Inc. All Rights Reserved

All information contained herein is believed to be accurate as of the date of publication, is provided “as-is” and is subject to change without notice. To review our full U.S. Legal Disclaimer, visit: https://bostik.com/us/en_US/privacy-policy/legal-disclaimer

All information contained herein is believed to be accurate as of the date of publication, is provided “as-is” and is subject to change without notice. To review our full U.S. Legal Disclaimer, visit: https://bostik.com/us/en_US/privacy-policy/legal-disclaimer