Which adhesives to use with LVT floor coverings?

What to consider when installing an LVT floor

I need to glue down LVT flooring.

Do you need to install an LVT floor? We have the perfect adhesive for a stress-free and long-lasting installation of your flooring.

You need a special high performance LVT adhesive.

I am installing an LVT floor in a kitchen or a bathroom.

Wet or humid rooms subject their flooring to heavy stresses. Only an adhesive perfectly suited to this environment will allow a lasting bond.

You will need a polyurethane or epoxy floor adhesive.

There are 3 different ways LVT flooring can be laid.

LVT (Luxury Vinyl Tiles) is PVC flooring that comes in the form of tiles or planks.

- Floating installation with click LVT tiles or planks

- Loose lay system utilising a high strength tackifier or pressure sensitive adhesive to resist lateral movement. This is only suitable for stable tiles under stable conditions

- Glue down installation where the flooring is fully and permanently bonded.

Everything you need to know before installing an LVT floor

Wondering which products you need to use for your LVT flooring project? Below you can find all the information you need for every unique solution.

Adhesive for LVT

Introducing the ideal adhesive for LVT flooring

In the absence of particular constraints related to the installation or the environment, and in the case of a glued installation of PVC flooring, use a high-performance adhesive. This type of LVT adhesive should offer a very high final cohesion to limit the dimensional variations of the flooring.

Do you plan to apply it in a domestic interior or are you going to apply it in busy areas with heavy foot traffic?

Stix A800 Premium

Bostik STIX A800 PREMIUM is a solvent-free acrylic adhesive with very low VOC emissions (EC1 Plus), and a powerful immediate grab.

Are you planning a loose lay installation?

Stix A740 Multi Best

Bostik STIX A800 PREMIUM is a solvent-free acrylic adhesive with very low VOC emissions (EC1 Plus), and a powerful immediate grab.

LVT adhesive intended for wet rooms

Two-part polyurethane adhesive

Bathrooms and kitchens are subject to strong constraints: humidity, frequent cleaning with detergents, etc. Gluing LVT flooring in this type of environment is possible provided you use a suitable adhesive.

STIX P956 2K

An adhesive with a high bonding performance for laying floor coverings subjected to heavy use or high mechanical or thermal stress. For the bonding of PVC, rubber, linoleum, carpets, synthetic grass and sports flooring.

High performance, high temperature flooring adhesive

LVT tiles or planks glued behind a bay window, conservatory, atrium or glass fronted building can be subject to considerable thermal change. The LVT adhesive needs to be very strong to prevent any deformation.

Stix A550 Power Elastic

Bostik STIX A550 POWER ELASTIC is a versatile, premium acrylic adhesive suitable for a wide variety of floor coverings. The solvent-free formulation has a low odour and very low VOC emissions (EC1 Plus).

Frequently Asked Questions

Selecting the right adhesive for your LVT installation depends on where and how you plan to use the floor. For standard residential areas with normal foot traffic, a pressure-sensitive acrylic adhesive provides excellent dimensional stability and high initial tack.

In areas exposed to temperature changes or direct sunlight, such as conservatories or rooms with large windows, choose a temperature-resistant adhesive that maintains strong bonding properties under thermal stress.

For commercial spaces experiencing heavy foot traffic or rolling loads, opt for a two-component polyurethane adhesive. This creates an extremely durable bond that withstands intense daily use while preventing movement or deformation of your LVT flooring.

For maximum performance with luxury vinyl plank flooring, pressure-sensitive acrylic adhesives deliver outstanding results in most residential settings. These adhesives create a strong initial bond while allowing for precise positioning during installation.

When working with larger spaces or high-traffic commercial areas, permanent bond adhesives provide enhanced dimensional stability and superior resistance to heavy rolling loads. Your subfloor condition also influences adhesive selection - concrete surfaces benefit from moisture-resistant formulations, while wooden subfloors require products that accommodate natural movement.

Remember that proper surface preparation significantly impacts adhesive performance. Clean, dry, and level subfloors ensure optimal bonding strength and prevent future installation issues.

Removing old LVT adhesive requires careful preparation and the right approach. Start by using a heat gun to warm the adhesive in small sections, making it more pliable and easier to work with.

A plastic scraper helps lift the softened adhesive without damaging the subfloor. Work horizontally rather than pushing downward to prevent surface scratches or gouges.

For stubborn spots, apply a specialist adhesive remover and allow it to penetrate for several minutes. Remember to test any product on a small area first to ensure compatibility with your surface.

Once the bulk of the adhesive is removed, clean the surface thoroughly with warm water and allow it to dry completely before any new flooring installation.

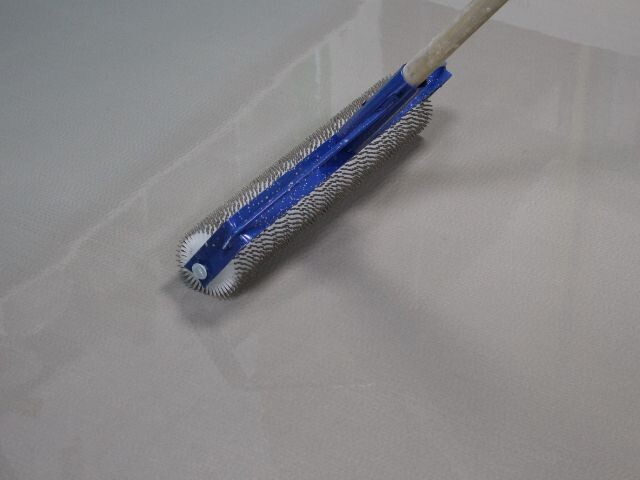

Successful LVT adhesive application relies on having the right tools at hand. You'll need a notched trowel, roller, and measuring equipment to achieve professional results.

Prepare your workspace by marking out the starting point from the center of the room. Apply the adhesive using your notched trowel at a 60-degree angle, working in manageable sections of 3-4 square meters. Keep the trowel clean throughout the process to maintain consistent coverage.

For optimal bonding, press tiles firmly into the adhesive making sure all the floor coverings backing is in contact with all the adhesive, rolling each section with a 50kg roller to eliminate air pockets. Work systematically across the room, maintaining straight lines and checking adhesive coverage on the back of tiles periodically.

For expert advice or further assistance, please contact your local Area Sales Manager: