Jan 17, 2019 - 10 min

Why Converting Processes Need Smart Functional Coatings

While conventional flexible packaging coatings serve as a protective layer, more converters are turning toward functional coatings instead, according to Research and Markets. Find out why this is the case, and the value smart functional coatings can bring to you.

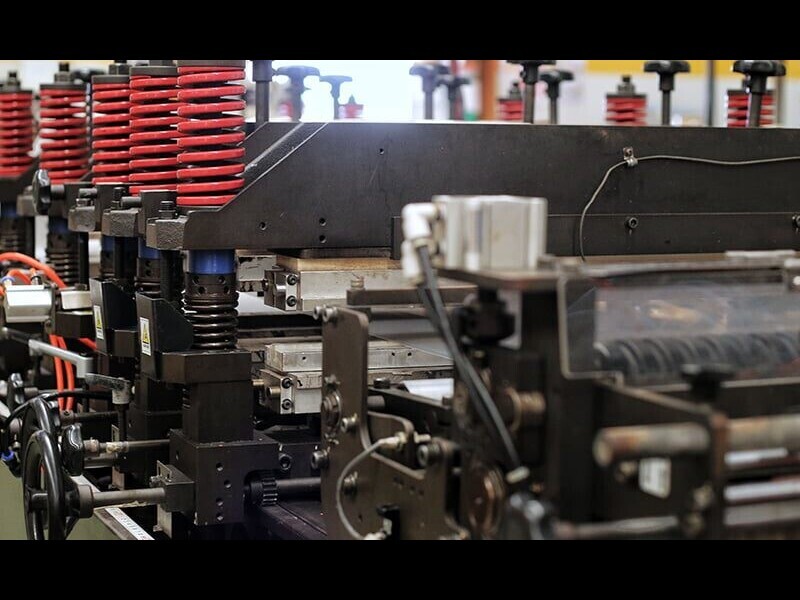

Smart Functional Coatings Improve Operational Efficiencies

Smart functional coatings meet several package requirements at once. For example, in addition to imparting a heat seal to adhere the lidding to the package, these coatings offer anti-fog capabilities to improve package clarity.

By combining both aspects into one coating, smart functional coatings are able to simplify converting processes and improve efficiencies.

End-use packages constructed using smart functional coatings are also enhanced. This is because they are able to reduce haze formation and improve barrier performance over traditional options.

Smart Functional Coatings Enhance Compatibility

Additionally, smart functional coatings offer enhanced compatibility on converting lines. This is because they are compatible with many commonly used lid and tray stocks and don’t require an extra sealing layer.

For other coatings, this extra sealing layer is required and causes additional line complexity as a result. It also causes end-use recyclability issues. Smart functional coatings, however, enable easy, single stream recycling.

Smart Functional Coatings Reduce Overall Costs

Furthermore, smart functional coatings help reduce overall converting costs. This is because they reduce the number of SKUs needed to achieve performance requirements. Instead, multiple needs are addressed in the one coating.

--

To learn more about these coatings and how they can help you, watch these short videos:

You can also visit www.bostik.com/us/anti-fog.