Oct 17, 2019 - 10 min

3 Ways the Right Low Pressure Molding Adhesive Helps Your Company

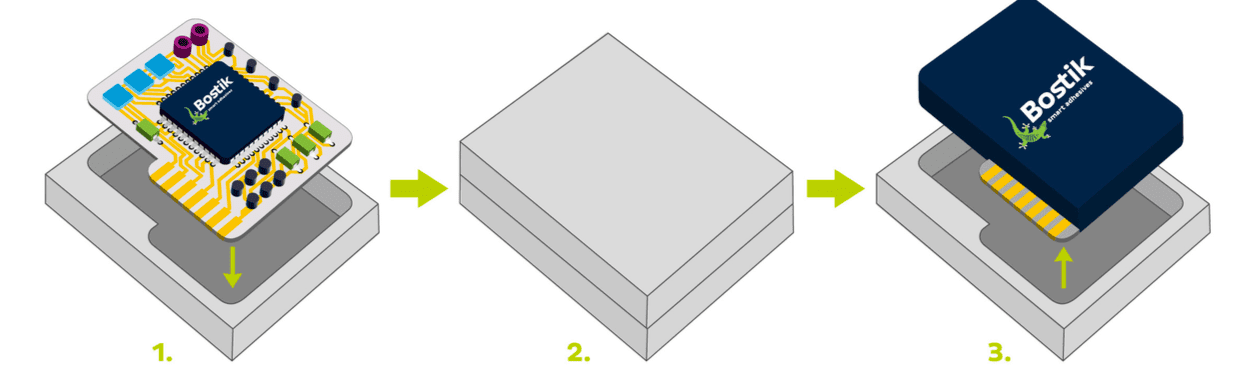

Low pressure molding is rising in demand given its ability to provide superior protection to electronics components. Yet while all adhesives used in low pressure molding aid in seal integrity and part protection, smart polyamide adhesives offer further benefits:

-

Improve Processes

-

Enhance End-Use Products

- High temperatures

- Shocks

- Harsh environments

- Solvents

-

Increase Sustainability