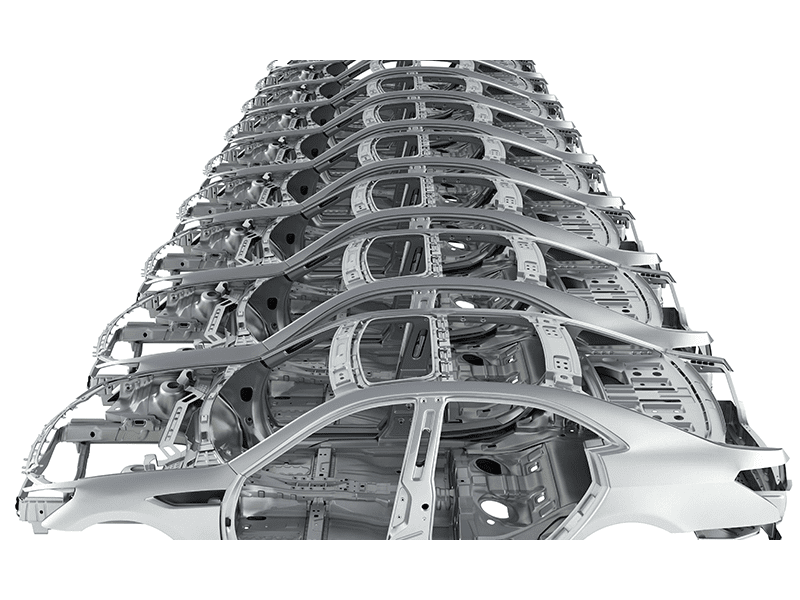

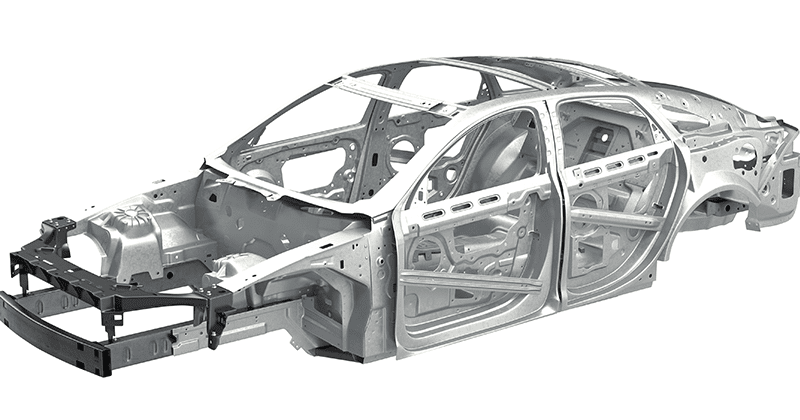

As the body-in-white market grows, slated to reach $90.5 billion by 2027, certain consumer trends are defining it. Find out how you can easily address them with elastosol adhesives.

1. Enhance Comfort

Today’s consumers look for vehicles that offer comfortable, quiet rides. Elastosols help address this trend in body-in-white applications by reducing noise, vibration and harshness.

2. Improve Aesthetics

Additionally, elastosols improve overall vehicle appearance. In particular, these bonding solutions:

- Enable increased design opportunities

- Protect against corrosion

3. Increase Sustainability

Further, body-in-white manufacturers look to reduce a vehicle’s carbon emissions, addressing both governmental regulations and appealing to consumer preference for environmentally friendly modes of transportation. Decreasing the vehicle’s weight is one way to do this. Elastosols bond to lightweight materials, such as:

- Fiber-reinforced plastics

- Aluminum

- Magnesium alloy

Elastosols also improve vehicle sustainability by enabling the use of:

- Solar cell and hydrogen-driven fuel systems

- Lithium batteries

These devices are necessary for electric and hybrid vehicles.

4. Heighten Safety

Today’s consumers also prefer vehicles that meet superior safety standards. Elastosols in body-in-white applications are designed to improve vehicle crashworthiness, boosting passenger safety.

--

In addition to meeting consumer trends, elastosols also improve vehicle manufacturing processes. For example, these bonding solutions:

- Improve worker safety

- Increase process quality and efficiency

- Extend shelf life product viability

Contact a Bostik representative today to learn how elastosols can help your body-in-white applications. You can also view this relevant content: