Mar 21, 2019 - 10 min

How Butyl Sealants Improve Watershield Assembly and Vehicle Performance

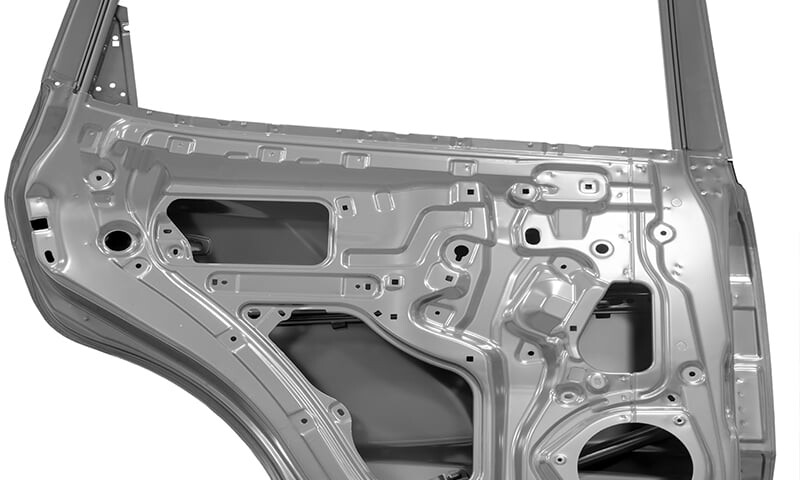

Necessary for protecting vehicle interiors from noise, vibration and debris, automotive watershields are an important aspect to automotive door panel assembly. As improving passenger comfort while increasing operational efficiencies remain top trends shaping the automotive market, watershields can also play a key role in addressing them. In particular, the right watershield sealant can help.

Find out how butyl sealants for watershield assembly improve production processes and end-use watershields overall, allowing you to more easily meet market trends.

Primerless

Butyl sealants do not require a primer when bonding to steel or aluminum substrates. Additionally, they are easy to apply and offer good workability. As a result, downtime is reduced and production efficiencies are enhanced. Further, by not requiring a primer, the room for error or bonding issues decreases as well.

Highly Flexible

As a synthetic rubber butyl-based sealant, these solutions are highly flexible and impermeable. This means they enable the watershield to offer enhanced protection from outside water sources for increased passenger comfort.

Permanently Tacky

Additionally, butyl sealants remain permanently plastic and tacky. As a result, they will not dry or crack. This capability enables extended watershield performance in protection door panel electrical components especially.

Highly Resistant

Offering excellent heat and humidity resistance, butyl sealants also enable extended watershield durability. By extending watershield durability, these sealants help improve the vehicle’s overall performance and longevity. They also give manufacturers the reassurance that the sealant will not fail in the field.

For more information on how butyl sealants can aid in your watershield assembly applications, contact Bostik today. You can also view this relevant automotive assembly content: