Jan 9, 2020 - 10 min

How Smart Thermal Conductive Butyl Adhesives Offer Advantages Over Thermal Mastics for Cooling Coil Bonding

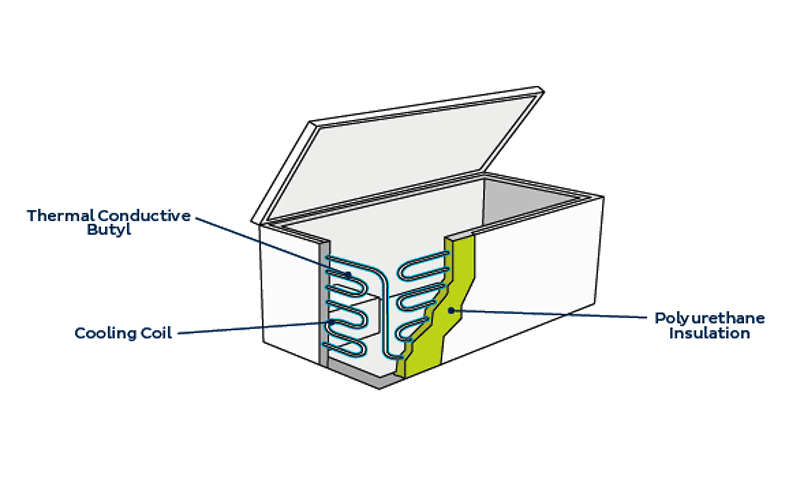

While cooling coils are essential in appliance assembly, the chosen adhesive to bond the coils to the refrigerator or freezer cabinet also is critical, as it can improve assembly processes while enabling the appliance to meet new energy savings classifications. Although thermal mastics are commonly used in cooling coil bonding, gain insight into how thermal conductive butyl adhesives offer distinct advantages.

- Energy Efficiency Improvements

- Decreased Adhesive Use

- Waste Reduction

- Precise Application