- Industrial

- Assembly

- Automotive

- Building & Construction

- Flexible Packaging

- General Transportation

- Rigid Packaging

- Tape & Label

Oct 21, 2020 - 10 min

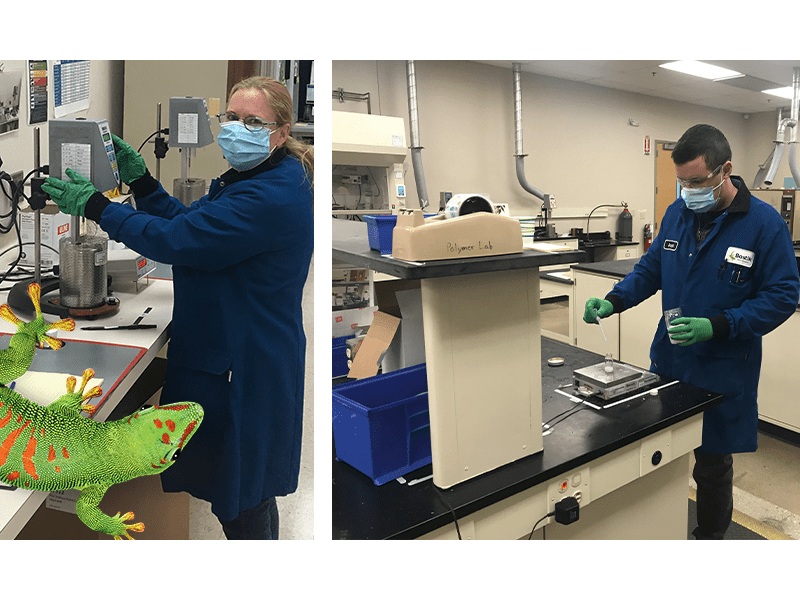

Thank You to Our R&D Team During National Chemistry Week!

Every October, the American Chemical Society recognizes National Chemistry Week, a community-based program that highlights the chemistry’s value in daily life. This year’s theme, “Sticking with Chemistry”, is focused on adhesives, making it particularly relevant our company.

We are grateful to R&D team of essential workers around the globe. Their dedication to adhesive chemistry research and development enables us to meet our customers’ needs across industrial, construction and consumer markets in the following ways:

Improved Sustainability

Our team of R&D experts understands our customers’ desire to make their processes and products more environmentally friendly. Through their extensive adhesive expertise, we’re able to help our customers:

- Reduce material usage and waste

- Enhance energy and fuel efficiency

- Improve product’s sustainable material use and end-of-life disposal

Two recent R&D adhesive innovations that help our customers improve sustainability include:

- Thermogrip® 43298 Our R&D team formulated the market’s first and only BPI-certified, compostable hot melt adhesive for paper and fiber board packaging applications, enabling our customers to manufacture sustainable packaging fit for industrial compostable facilities.

- Aquagrip® 3720: Thanks to our R&D team’s expert chemistry knowledge, our customers can use a water-based adhesive for automotive interior assembly to reduce environmental impact and improve worker safety.

Increased Performance

We also appreciate our R&D team’s ability to use adhesives to increase our customers’ product performance. These adhesives allow our customers to:

- Expand their design opportunities

- Meet consumer demands for enhanced aesthetics

- Extend product longevity and durability

A recent R&D adhesive innovation that enables our customers to increase performance includes:

- Brilliance™: Our R&D team formulated an elastic adhesive that allows customers to incorporate more cost effective, thinner materials into their diaper production while enhancing performance and user comfort.

Enhanced Efficiencies

Further, our R&D team understands the importance of efficiency for our customers and have formulated adhesives that enable them to:

- Complete production with minimal downtime

- Streamline operations with increased ease of use

- Improve process flexibility with repositionability

A recent R&D adhesive innovation that helps our customers enhance efficiencies includes:

- Bosti-Set™: Thanks to our R&D team’s extensive understanding of application needs, this tile panel adhesive reduces installation time by as much as 50% while decreasing installation complexity.

On National Chemistry Week and every week, we are grateful for our R&D team’s ability to formulate adhesives that give our customers’ the results they need and the products they deserve.

Interested in joining our R&D team of essential workers and formulating adhesives that make a difference for our customers and our lives? Click here for a Bostik career opportunity near you.

Contact a Bostik expert to learn more about how our R&D team remains mobilized to help even in these unprecedented times.