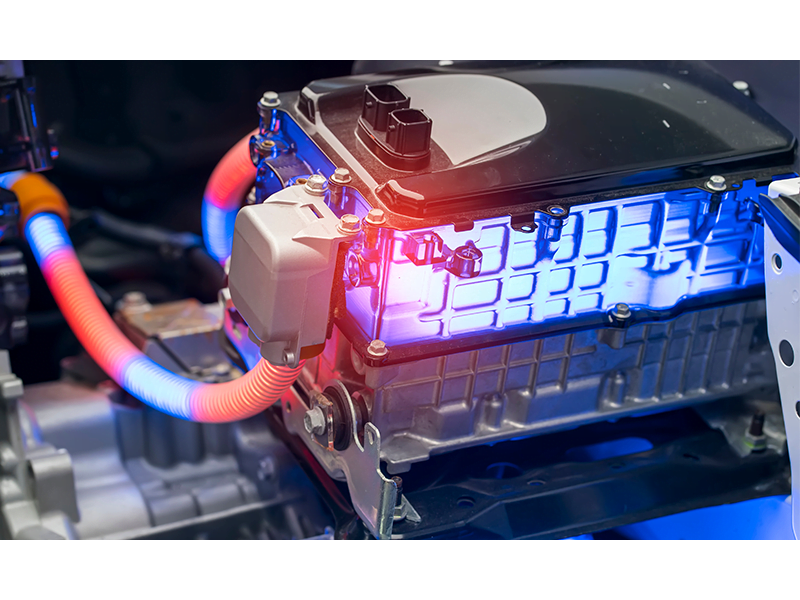

While electric vehicles (EVs) are gaining momentum, projected to grow at a CAGR of 22.4% through 2025, there have been some challenges to manufacturing EV batteries. Fortunately, adhesives can help address these challenges in the following ways:

Increase Battery Range

One of the most critical components of EV batteries is ensuring they offer sufficient longevity. Adhesives are a lighter weight option than traditional mechanical fasteners and help reduce overall vehicle weight. This increases battery range. Additionally, by adding stiffness and strength to EV battery packs, adhesives allow for lighter weight materials to be used in its manufacturing. This further reduces EV weight.

Enhance Battery Protection

Additionally, when bonding EV battery packs together, adhesives are able to protect the battery from the outside elements, such as:

- Water

- Dust

- Road salt

- Automotive fluids

They also protect EV batteries from mechanical shock and vibration. This enables batteries to be more durable and last longer.

Improve Battery Safety

Further, adhesives can be formulated to slow or stop fires if EV batteries become overheated or damaged. This is because adhesives are able to be thermal conductors or insulators, depending on if the battery is actively or passively temperature controlled.

--

View The Adhesive and Sealant Council’s white paper on “Adhesives and Sealants in Battery and Hybrid Electric Vehicles” for more details. Bostik, a global leader in automotive adhesives and sealants, contributed toward the information in the white paper. Contact a Bostik expert today to learn how our solutions aid in a more sustainable environment.