Feb 1, 2021 - 10 min

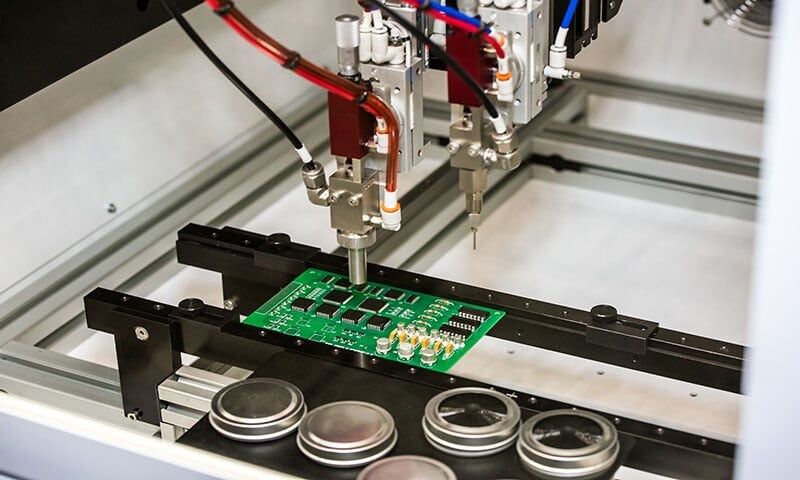

How Adhesives Solve Challenges In Electronic Device Manufacturing

Adhesives play a critical role in the electronic device manufacturing market. Electronic devices are constantly evolving, getting more complex and smaller in size. Therefore, manufacturers depend on innovative adhesives to easily adapt to the challenges of new device designs and production processes.Learn how three challenges in electronic device manufacturing can be alleviated with innovative adhesives.

Challenge #1: Production Inefficiencies

Electronic devices are almost constantly in high demand, so efficient production time is vital to meet consumer needs.In the past, manufacturers have used soldering or mechanical fasteners to join electronic device components together. However, these methods can cause inefficiencies for several reasons.Using mechanical fasteners may add production time due to additional steps including surface preparation, drilling holes and tightening fasteners. These additional steps can not only add complexity, but they could also increase the likelihood of error and part failures, further slowing the process and contributing to production inefficiencies and higher costs.

Alternatively, adhesives have properties that enable increased production efficiencies:

- Simplified application: Many adhesive options require minimal surface preparation and can be applied using automated application methods, mitigating production steps and improving efficiency. Adhesives also offer precise application, reducing error likelihood on increasingly small parts.

- Reduced overall cost: With increased ease-of-use, adhesives can help you avoid downtime during production and reduce waste, helping to reduce overall cost.

- Improved Performance: Since adhesives are applied to the entire surface, they will offer increased strength over an area versus making a point bond with a fastener or screw. This becomes important as devices get smaller, decreasing surface area for bonding.

Challenge #2: Design Limitations

Consumers often value aesthetics in their electronic devices. Over time, devices have become smaller and thinner to keep up with aesthetic and

functional demands, causing some challenges during assembly. For example, using metal fasteners to assemble electronics can create a bulkier, heavier device. Soldering can provide a low-profile bond; however, it can easily rust and weaken if exposed to moisture. Both of these methods also pose limitations in the design process; mechanical fasteners may require holes to be drilled in components. Similarly, soldering cannot always bond two dissimilar substrates together, like metal and rubber. These limitations may inhibit the manufacturer’s ability to create thin, lightweight devices with their desired materials.

Adhesives provide flexibility to work with thinner substrates and meet demands for visual aesthetics.

- Smooth appearance: Adhesives will add only marginal weight to the device. Many require only a small amount of material to provide strong performance, helping to avoid a bulky appearance and provide a more elegant design.

- Resistance to harsh environments: Many adhesives provide resistance against heat, cold temperatures, UV rays, water and other chemicals. If your device will encounter these conditions, be assured your adhesive will maintain performance.

- Versatility: Adhesives can be applied cleanly and create a low-profile bond that won’t disrupt the aesthetics of thin devices. They can also work with a wide variety of substrates to bond dissimilar surfaces together.

Challenge #3: Delicate Components

Electronic devices contain many small, delicate components that can be easily damaged during assembly. Mechanical fasteners can increase the likelihood of damage, as they create stress concentration points that can lead to premature failure. Additionally, drilling holes in the pieces that are being joined can weaken the material. While soldering or welding can alleviate stress concentration points, they can cause the device’s material to alter when exposed to high heat. This can lead to distortion of the component, which could impact the device’s performance or require additional steps to resolve.

Adhesives can help keep delicate components free of damage during production in the following ways:

- Even stress distribution: Unlike mechanical fasteners, adhesives distribute stress evenly across the bond line. This helps reduce breakage or cracking when the device is assembled.

- Reduced deformation: Some adhesives require heat to cure; however, there are many options to choose from, including UV or room temperature curing, so you can find a solution that will not cause component deformation.

How Bostik’s Born2Bond Can Improve Your Production Process

If you’re considering switching to adhesives for your electronic device manufacturing process, Bostik’s Born2Bond products may be right for you. Born2Bond’s range of high-performance, fast-curing ‘by-the-dot’ instant adhesives help you create a faster, stronger, more precise bond. These low-bloom solutions also offer significant aesthetic benefits for high-end electronics, reducing the risk of spoilage and waste. Contact a Bostik representative today to request a sample, or learn how Born2Bond can help you overcome challenges in your production process.

You can also check out this other relevant content: