May 24, 2021 - 10 min

How Modified Silicone Sealants Make Window and Door Manufacturing Easy

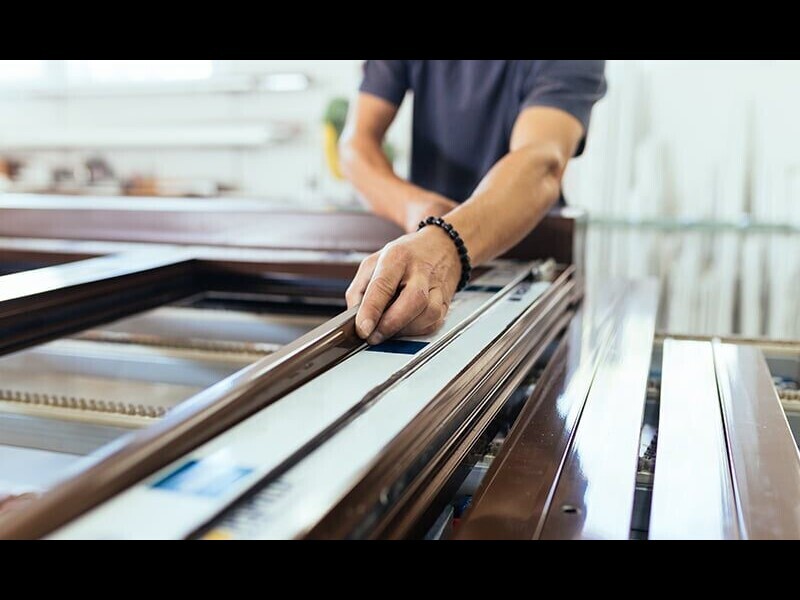

Sealants play an important role in window and door manufacturing. An improper sealant can cause operational issues, plant downtime and end-use performance challenges. Therefore, it's important to choose the right product to avoid issues and improve performance. Find out how modified silicone sealants make this possible - and easy. Fast Skin Time There are many window and door sealants currently on the market. However, many of these options possess a skin time length that impacts manufacturing efficiencies. Modified silicone sealants offer a skin time of just six minutes. This fast skin time means the sealant provides following advantages:

- Decreased likelihood to pick up dust and dirt

- Reduced wait time before painting over it

Easy Gunnability

Additionally, modified silicone window and door sealants flow easily through a sealant application gun. Aiding in process efficiencies, these solutions work well on manufacturing equipment and are easily extrudable.

Paintability

Furthermore, modified silicone sealants can be painted over quickly after application, unlike other options. For example, if polyurethane is painted too soon, the paint can bubble or separate. Painting silicone also can cause manufacturing challenges. Modified silicone sealants' easy paintability, on the other hand, helps increase the bond between the paint and sealant. This is because it is a moisture-curing product, which helps the paint dry faster and bond the paint polymer to the sealant. As a result, modified silicone sealants are able to help in the finishing process for window and door manufacturing.Other Benefits

Easy to clean up and ambient-applied, they can be colored to suit a variety of application needs. They also are able to bond to multiple types of substrates, such as:- Wood

- Vinyl

- Aluminum

- Glass