Apr 29, 2022 - 10 min

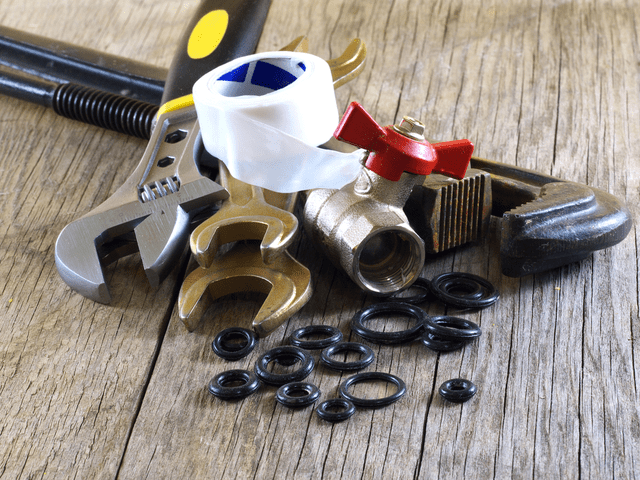

Five Reasons Your Plumbers' Tape is Not as Good as You Think

When managing MRO assembly lines, it’s important for manufacturing plants’ pipes to be properly sealed and keep water, air, chemicals and other items properly sealed within them. To do so, many manufacturers have traditionally used plumbers’ tape, also called PTFE tape, deeming it sufficient for their needs and not considering an alternative unless an overt problem arises with it. However, they may not realize that plumbers’ tape inherently causes and even masks problems; they simply may view aspects like clogged filters and spill mats, to name a few, to be standard across all plants. Simply put, they may not realize that these are actually problems to address and that what they view as a go-to pipe solution, plumbers’ tape, is in fact holding their plant back from reaching its true efficiency potential.

Fortunately, there is a solution that not only properly seals pipes, it improves equipment performance in key manners and increases worker safety. Gain insight into five reasons plumbers’ tape isn’t the ideal solution your plant may think it is and how an alternative can provide long-term solutions to better your plant overall.

Reason #1: Clogged Filters

While plumbers’ tape serves as a lubricant to help torque threads together, it is designed to shred off as the lubricant is exposed. These shreds can get caught in pipe lines and filters, which cause clogging and take significant downtime to fix. Additionally, depending on the environment, the shredding can also cause metal to metal contact, which can yield further problems.

Reason #2: Leakages

Because plumbers’ tape does not provide a true seal nor account for thermal expansion, it’s possible for pipes to leak their contents onto plant floors. To address this, many plants use spill mats. However, this solution isn’t 100% effective and doesn’t solve the problem; it simply masks it. Workers may still slip or fall due to the leaks.

Reason #3: Corrosion

Plumbers’ tape serves as a lubricant for getting parts together but also works as a lubricant at getting them apart. Since it does not create a 100% seal, this can cause a path for moisture to get in between pipes and corrosion to occur.

Reason #4: Equipment Vibration

Additionally, plumbers’ tape does not entirely seal to the threaded connection. This can cause the equipment’s connection to loosen from vibration.

Reason #5:Improper Application

Plumbers’ tape may seem like a quick fix; however, to apply it properly is trickier than it may seem. The tape must be wrapped a certain way to effectively apply it to the pipe threads. When the tape is not correctly applied, it may need to be replaced, which adds downtime while also further increasing likelihood of clogged filters, leakages and corrosion.

Introducing an Alternative to Plumbers’ Tape: Anaerobic Pipe Sealing

What is Pipe Sealing?

Pipe sealing is an anaerobic adhesive product that unitizes pipe thread gaps, creating a true seal. Its capabilities address key limitations with plumbers’ tape, enabling plants to become proactive instead of reactive, increase efficiencies and reduce costs overall. In particular, pipe sealing:

Eliminates clogged filters

By unitizing a seal rather than covering it up, there is no material that shreds during use and gets stuck within filters. Pipe sealing also eliminates potential infiltration from metal-to-metal contact with shreds.

Mitigates pipe leakages

Because pipe sealing provides a 100% seal, the pipes’ contents do not leak out onto the floor, mitigating the need for spill mats and reducing accident likelihood.

Prevents corrosion

Pipe sealing’s 100% seal and coverage account for thermal expansion and provides protection even in high-moisture environments, unlike plumbers’ tape. As a result, air and moisture are unable to infiltrate in between pipes, which means corrosion does not occur. This extends part longevity and reduces maintenance needs.

Reduces equipment vibration

Pipe sealing creates a flexible bond between two machinery components and accounts for thermal expansion to reduce vibration levels. This also helps reduce mechanical failure and keeps operations moving.

Increases application ease

Additionally, pipe sealing is easy to apply and can fit in toolkits for on-the-spot needs. The application process is quick with no additional equipment needed. Additionally, it does not need to be fixed or reapplied, unlike plumbers’ tape.

Why Choose Bostik’s Born2Bond™ Pipe Sealing

Bostik’s Born2Bond, pipe sealing, anaerobic adhesive product offers a long-lasting, efficient bonding option over plumbers’ tape. Single-component, solvent-free and easy to clean, it is suitable for all types of threaded metal pipes and fittings for both new and existing equipment. Additionally, it fills and seals all voids, providing 100% surface-to-surface contact and achieving a cohesive, durable connection that does not fail even when subjected to:

- Extreme temperatures

- Chemical substances

- High vibration levels

Are you ready to switch to pipe sealing and help your plant reach its potential? Contact a Bostik representative to learn how you can easily make long-lasting changes to your maintenance processes.

Interested in other MRO products? Learn more about our other anaerobic adhesives for MRO needs here.