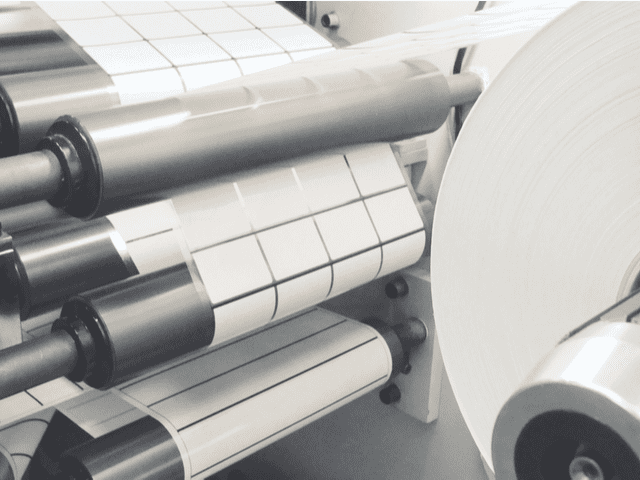

Industries around the globe are currently facing significant challenges with supply chain disruptions and raw material shortages. For the label market especially, these challenges impact converters’ ability to manufacture labels at the desired price points with the necessary performance levels and within a given timeframe.

At Bostik, we understand how stressful this can be for your company and are continually working to mitigate the impact. In particular, our abilities to provide cost-effective products and flexible formulations enable us to offer label adhesives that address key concerns, ensuring customers get the label adhesives they want when they need them.

Ability to Provide Cost-Effective Products:

With raw material costs rising, customers are realizing they may be using products that are over-engineered for their actual applications. In the past, there hadn’t been a need to compare the product performance and application needs; but that’s no longer the case. Now, they simply want a product that meets only end-use performance needs.

We understand the desire for this shift and offer general purpose label adhesives to address it. These adhesives enable customers to address multiple, versatile application needs with one product, reducing SKU volumes and overall product costs. This is because they possess a wide-temperature range as well as broad peel and stick capabilities. Further, our general-purpose adhesives still meet label performance needs, allowing customers to receive the results they’ve had in the past while also reducing cost without sacrificing performance.

Ability to Provide Flexible Formulations

Customers are also concerned about product delays due to raw material sourcing constraints. We understand how these delays often have a domino effect, making it harder for our customers to then meet the needs of their customers.

To mitigate these delays, Bostik’s R&D experts can create flexible adhesive formulations. Rather than solely relying on one raw material to formulate adhesives, they can use different options that are chemically identical to the raw materials in short supply. These offset materials are tested to ensure the finished adhesives offer the same performance level as the original raw materials. As a result, we can provide our customers with the label adhesives they want within the timeframes they need, helping them more efficiently manufacture their end-use labels.

More Ways Bostik Helps Customers

Our Bostik team is constantly thinking towards the future, making sure our product designs today can address tomorrow’s needs. In particular, this means manufacturing adhesives that have strong bonds for evolving substrate types and the ability to perform under increasingly stringent conditions. Additionally, with today’s current supply challenges, we continue to search for alternate supply sources, monitor and update lead times to ensure we purchase materials on time and carry backup safety stock. Further, our team works directly with customers to customize formulations that will fit their needs and allow for on-time product delivery.

Do you need help with managing supply for your label adhesives? Contact a Bostik representative to learn how we can help your processes continue without delays.

Other tips to boost label manufacturing efficiencies:

Tips to Ensure Successful Label Converting

Can Your Shipping Labels Withstand Ecommerce Changes?

How to Boost FMCG Label Manufacturing Efficiencies, Product Quality