Sep 12, 2022 - 3-5 min

How to Overcome Common Label Manufacturing Challenges

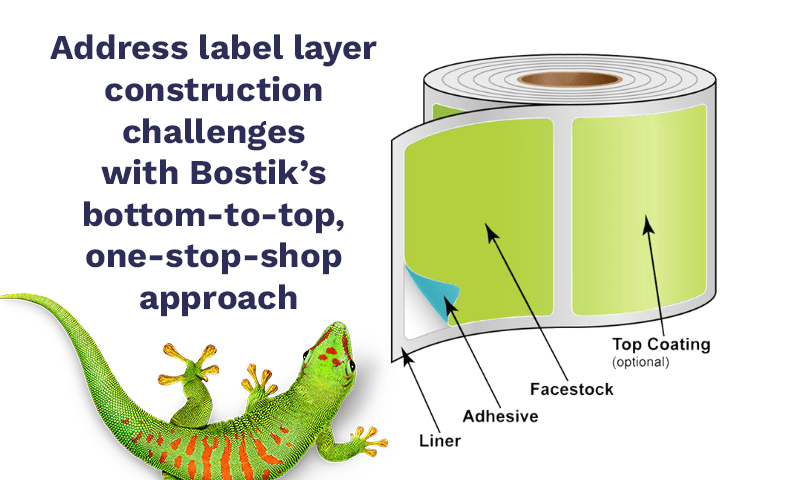

Label manufacturers know there is a lot that goes into ensuring labels provide the necessary requirements for the appropriate end-use. This typically involves ensuring strong adhesion to tough surfaces, easy removability without leaving residue behind, ability to maintain a bond after repeated wear and tear as well as moisture or temperature resistance. However, in addition to ensuring the finished label is equipped to handle the requirements, it’s a good idea to understand the role each of the label layers play in making its abilities possible and how to make the right material selections to easily accomplish performance goals. This can be challenging, especially considering that each layer, the liner, adhesive, facestock and top coating, come with additional decisions to make regarding development, sourcing materials and manufacturing efficiencies. Each of these items can become especially costly and time-consuming if there are any setbacks.

Fortunately, Bostik offers a bottom-to-top, one-stop-shop approach that can benefit all label manufacturing needs and make it easy. Learn how our method for label construction addresses challenges and offers additional benefits to manufacturing processes.

Challenge #1: Choosing the Right Solutions for Label Layer Compatibility

Challenge #2: Choosing the Right Solutions for Increased Production Efficiencies and Reduced Carbon Footprint

Solution: Bostik’s Bottom-to-Top, One-Stop-Shop Solution for Label Manufacturing

By utilizing Bostik’s bottom-to-top, one-stop-shop approach, manufacturers will gain more than just the desired end-use in label construction. The Bostik team, with its parent company Arkema, have the global capabilities to solve problems above, below and in between the substrates of label applications. Along with our wide portfolio of adhesives and coatings that enable streamlined solutions, our team of Bostik experts allows us to provide the necessary testing and recommendations manufacturers need to reach high performance levels and production efficiencies.

What is the bottom-to-top, one-stop-shop approach?

A bottom-to-top, one-stop shop approach allows manufacturers to rely on Bostik as both a supplier and industry expert for all labeling layer solutions, ensuring all the formulations will be cohesive together and offer high performance along with improved manufacturing efficiencies that reduce a facility’s carbon footprint. Unlike competitors, Bostik is the only one to offer a bottom-to-top, one-stop-shop solution by working on a global scale to ensure manufacturers receive the material supply necessary to benefit end-use labels. Our approach will help address the challenges noted above in the following ways:

- Streamlined process to achieve label layer compatibility: We offer a large portfolio of technologies that have been proven through testing to offer strong bond strength, easy peeling, environmental protection and durability. These technologies include pressure sensitive, laminating, reseal, solventless, hard coats, coatings and varnishes. Our team of experts can answer questions and provide suggestions on a wide range of formulations, allowing manufacturers to learn all options at once rather than spend extra time reaching out to multiple sources. Further, we’ll help determine how label layers will bond cohesively according to the desired label construction and which technologies work best together across layers. With global access to raw materials, manufacturers don’t need to worry if one raw material is in short supply; we can obtain a similar option that will provide the same needed results while ensuring it works with the other layers. This saves manufacturers time, costs and resources to find different products when one isn’t available.

- Increased process efficiencies: We understand all aspects that can impact the manufacturing stream, including potential processing challenges. By offering a bottom-to-top approach, we are able to provide adhesive technology recommendations that can run efficiently on existing lines for the entire label, eliminating the need to purchase additional equipment. Further, if manufacturers discover production issues that are adding extra downtime, we will help identify a solution that allows lines to reduce hold-ups and move at a fast, consistent rate to produce more products in a given time frame. Additionally, we conduct testing so production lines do not have to pause. This enables manufacturers to speed up the development phase and find a solution faster, reducing costs that would otherwise go to extensive testing efforts or additional operations to meet daily production demands.

- Reduced carbon footprint: We understand manufacturers not only have specific needs, but they are also trying to offer labels that are ahead of the curve and meet industry trends such as sustainability. Our team is continually developing sustainable label solutions that contribute to increased recyclability and therefore can offer suggestions and solutions that enhance sustainability through each label layer. We provide several options that possess easy wash-off capabilities, are formulated with bio-based materials and reduce material usage, such as linerless and cold seal bonding solutions. Additionally, we can share the best production practices that will enable reduced energy use and waste throughout facilities, helping decrease carbon footprint.

Want to learn how Bostik can help with your specific label application needs with our bottom-to-top, one-stop-shop approach? Contact a Bostik representative today to learn how we can ease your label layer processes.

Here are just a few examples of how we can benefit your label manufacturing:

Mitigate Key Label Supply Chain Issues

Improve Ecommerce Package Fulfillment with the Right Adhesives