Jan 12, 2022 - 10 min

Improve Ecommerce Package Fulfillment with the Right Adhesives

Ecommerce has grown exponentially in recent years due to consumer demand for more convenient shopping options. In fact, some of the top ecommerce platforms have experienced about a 71% increase in retailers turning to online sales. However, the increase in ecommerce demand requires brand owners to ship more products faster and more efficiently than ever before. Therefore, ecommerce package manufacturers are feeling pressure to meet the rising need, so they stay competitive in the growing industry.

Fortunately, the right adhesives help ecommerce package manufacturers address brand owner demands to get their product packaging delivered on time, secure and undamaged to their proper destination as well as in a manner that will resonate with consumers. Find out how they boost efficiency, increase quality and improve sustainability, and what you should consider before making your ecommerce package manufacturing adhesive decisions.

How the Right Adhesives Boost Ecommerce Package Efficiencies

Increasing production line efficiencies is key to meeting heightened ecommerce packaging output demands. The right adhesives enable manufacturers to:

Reduce SKUs: When using corrugated packaging materials, the right adhesives enable manufacturers to use one SKU to bond across production lines. By having just one to track, they can keep tabs on adhesive stock much more easily. Further, production line speeds can increase, since there is no need to change out and test adhesives for each line. Manufacturers are also able to maintain better space utilization and organization.

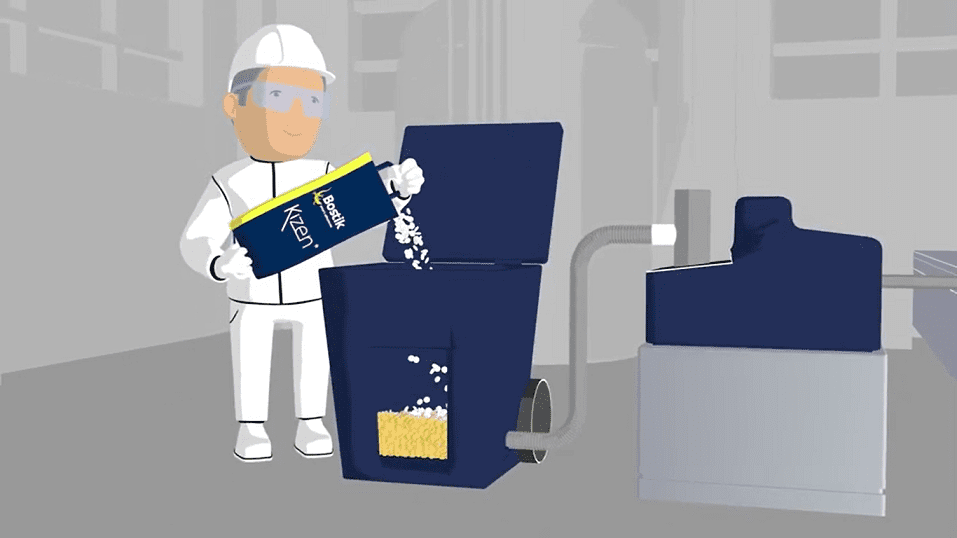

Decrease downtime: The right adhesives are designed for auto-feed application methods and offer low nozzle clogging and stringing capabilities. As a result, fewer line stops are needed to clean the equipment compared to other technologies. Additionally, they can be added directly over existing adhesives in the tank; no purging is needed first.

Increase line speeds: By choosing the right adhesives with fast set speeds, the bond will adhere to the corrugated boxes in a timely manner, furthering plant productivity. Additionally, by offering good fiber tear, they can withstand variety of application temperatures, which helps simplify and speed up manufacturing processes.

How the Right Adhesives Increase Ecommerce Package Quality

In addition to boosting efficiencies, the right adhesives increase ecommerce packaging quality by offering the following:

Enhanced bond security: Ecommerce packaging is exposed to a variety temperatures before reaching the desired destination. The right adhesives offer a wide temperature range, maintaining performance throughout weather and climate extremes. Additionally, the right adhesives provide durable bonding to difficult substrates, such as ones with shorter paper fibers and low surface energy. Without this capability, the package may open prematurely, resulting in customer dissatisfaction.

Reduced pop-opens: The incorrect bonding technology may cause ecommerce packages to “pop open” on the manufacturing line or in transit. Fortunately, the right adhesives offer enhanced thermal stability and low viscosity. This allows a strong bond to difficult substrates, reducing poor flap folding compression, minimizing the compression hold time and increasing overall quality.

How the Right Adhesives Enhance Ecommerce Packaging Consumer Appeal

Along with boosting efficiencies and increasing quality, the right adhesives help packaging resonate with consumer preferences for reduced environmental footprint. In particular, they yield:

Reduced overall package weight: The right adhesives offer intermittent coating patterns, which enable less adhesive consumption per package and overall lighter package weight when compared to other technologies. Additionally, this capability helps reduce the packaging weight on delivery trucks to improve fuel efficiency and reduce consumer shipping costs.

Increased volume of sustainable materials used: According to Corrugated Packaging Alliance, corrugated is the single most recycled packaging material; further, nearly half of a corrugated box contains recycled fiber. The right adhesives form fast and strong bonds to even the most difficult sustainable substrates, such as highly-recycled boardstock. This is due to their ability to sufficiently wet out, which is important when a substrate includes graphics or coating. Other technologies are often unable to sufficiently bond to sustainable substrates. This hinders the manufacturer’s ability to reduce environmental footprint without sacrificing quality.

How Bostik Can Help with Your Ecommerce Package Manufacturing:

Bostik’s Kizen® product line can easily help you fulfill your ecommerce packaging demands to ensure efficiency, quality and ability to resonate with consumers preferences. These hot melt adhesives, designed for case and carton sealing applications, offer efficiency and quality improvements compared to other technologies and enable improved package sustainability overall.

To stay competitive in the ecommerce packaging market, contact a Bostik representative today to request an adhesive sample and learn how we can enhance your manufacturing processes.

Other content about Kizen:

How Kizen’s Broad Capabilities Improve Your Packaging Plant and Production Lines

On-Demand Education Series: Kizen Hot Melt Adhesives

New Case and Carton Sealing Technology Solves Pop-Opens, Reduces Material Usage