Sep 29, 2025 - 3-5 minutes

Achieve Three Key Electronics Performance Needs With One Solution

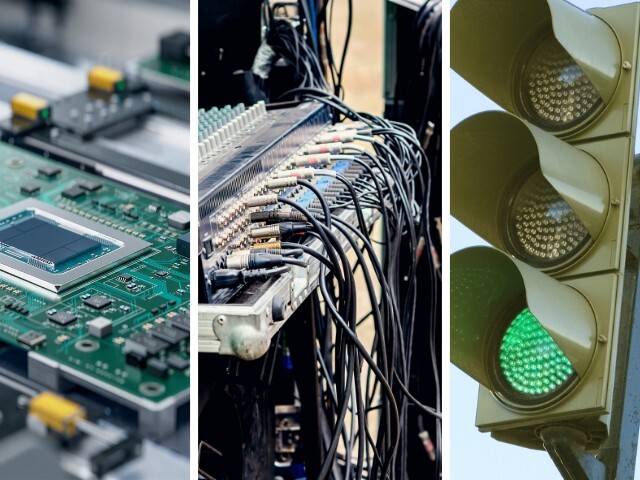

Learn how Thermelt® 964 hot melt polyamide resin meets three key performance needs— flexibility, reliable adhesion and UV resistance— for low pressure molding in PCBs, LED encapsulation and outdoor electronics.

When manufacturing electronic components such as printed circuit boards (PCBs), light-emitting diode (LED) encapsulation and outdoor electronics, it’s important for your low pressure molding (LPM) to achieve these performance goals:

- Flexibility at low temperature

- Reliable adhesion

- UV resistance

Your LPM bonding technology can help.

However, it can be challenging to address the goals with one LPM solution; you may be using more than one within an application. This can result in unbalanced or less than desirable performance levels amongst the three performance demands.

Until now.

Learn about a new LPM resin that can help you achieve these three key demands without compromising performance levels.

Performance Demand #1: Flexibility

Flexibility is a critical performance demand in low pressure molding for electronic components, as it helps address vibration, thermal expansion and mechanical stress during installation or use. Without sufficient flexibility, the molded material can crack, detach or fail to protect sensitive electronics, which can lead to compromised reliability. This can be especially problematic in outdoor or high-vibration environments, where rigid materials may fracture or lose their seal over time. If the material cracks or breaks, it may also impact:

- Protection against moisture, dust and other environmental hazards, which can lead to reduced performance or even damage and shorten the overall lifespan.

- Production costs, as the material may need to be repaired or require replacements.

Further, achieving flexibility at low temperatures in LPM formulations can be difficult when strong adhesion is also required. Most resins that offer excellent adhesion tend to be rigid; this is because achieving increased adhesion also requires having increased tensile strength, which tends to have low flexibility. Therefore, this limits the adhesives’ ability to flex with the substrate or absorb mechanical stress. This may mean manufacturers must choose between adhesion or flexibility - a compromise that may weaken overall performance.

Performance Demand #2: Reliable Adhesion

Reliable adhesion is essential in low pressure molding for electronic components, because it helps ensure the resin forms a durable, protective bond with the substrate, such as a PCB, wire junction or LED housing. Like flexibility, adhesion also contributes to keeping moisture, dust and other contaminants from infiltrating the component, which is critical in harsh or outdoor environments for long-term protection.

However, achieving reliable adhesion can come at the expense of other performance demands. This is because rigidity that can be associated with the reliable adhesion can reduce the LPM resin’s ability to flex or shift with the component or withstand prolonged exposure to UV and can lead to cracking, deterioration or yellowing over time.

When adhesion is compromised, the encapsulated component can experience decreased or failed strength. This can lead to:

- Increased downtime for rework or replacements, also resulting in additional costs

- Negative impacts for brand reputation and customer trust if end-users experience product failures sooner than expected for the product’s intended lifespan

Additionally, existing low pressure molding solutions that offer reliable adhesion may not be designed with sustainability in mind. They may rely on solvent-based materials that can be difficult to recycle or dispose of responsibly. While LPM processes provide a more sustainable alternative to methods such as potting, there continues to be a gap if the LPM resin’s formulation does not incorporate more environmentally friendly materials.

Performance Demand #3: UV Resistance

UV resistance is a vital yet often overlooked performance demand in low pressure molding for electronic components, especially those used in outdoor environments. Cables, connectors and LED housings exposed to sunlight on a regular basis can be vulnerable to degradation from ultraviolet radiation. A lack of adequate UV protection can lead to:

- Compromised appearance and long-term performance due to brittleness, discoloration or cracking over time

- Increased maintenance, replacements and potential system failures, which can result in additional costs for manufacturers

Therefore, you ideally want to use a resin that offers this protection without compromising on flexibility or adhesion. Even if your LPM resin offers UV resistance, it’s possible that other UV resistant materials used require additives or structural modifications. These can interfere with the resin’s ability to bond effectively or remain flexible under stress.

The Solution: Introducing Thermelt® 964

Hot Melt Polyamide Resins

With Thermelt® 964, a hot melt polyamide resin for low pressure molding in electronic components, you no longer have to compromise. You can receive high flexibility, reliable adhesion and UV resistance in one solution. It offers a balance formulation that can meet all three critical performance demands:

Low Tg for flexibility:

Thermelt® 964 features the lowest glass transition temperature (Tg) in the Thermelt® range, allowing it to maintain flexibility even at low temperatures (down to -76°F (-60°C)) compared to other polyamide resins.

Reliable adhesion with bio-sourced content:

Not only does Thermelt® 964 deliver reliable adhesion to a variety of substrates including PCB, wire junction or LED housing, the hot melt polyamide technology is containing high content of bio-based raw material using dimer fatty acid to reduce environmental impact. This means your adhesive can help you move one step closer to improving your overall environmental footprint with your product offerings.

Built-In UV Resistance:

Thermelt® 964 offers the most UV resistance in the Thermelt® range. When UV protection is a priority, especially in outdoor applications, this resin is the top Thermelt recommendation.

Simplified Processing Advantages

By combining flexibility, adhesion and UV resistance in one solution, Thermelt® 964 also streamlines your production process by offering:

- Easy Integration Into Existing LPM Equipment: Thermelt® 964 is designed to work seamlessly with standard LPM equipment. That means you can upgrade your performance capabilities without investing in new tools or reconfiguring your production line.

- Simplified Material Handling: Managing one low pressure molding resin instead of several makes training, setup and day-to-day operations more efficient. With Thermelt® 964, you’ll spend less time switching materials, which helps reduce errors and improve throughput.

- Reduced SKUs: Instead of sourcing and managing multiple resin formulations to meet different performance demands, Thermelt® 964 allows you to consolidate into a single SKU. This simplifies procurement and reduces inventory complexity.

- Decreased Inventory: With Thermelt® 964, you can optimize your inventory and free up resources for other operational needs.

Why Work With Bostik And Use Thermelt® 964

As the adhesives solutions segment of Arkema, Bostik’s team of experts can provide the knowledge you need to implement Thermelt® 964, as well as other Thermelt® products into your production. We are here to provide:

- Technical support: From trial testing to troubleshooting assistance, our team members consist of LPM experts and specialists who can offer in-person support with your assembly. We work with you to test your materials with our product range, helping to ensure you find the best solution for your performance needs. Further, we’ll assist with getting the solution to operate efficiently on your production lines. We also offer support with product training and using automated dispensing equipment properly.

- Reliable partnerships: We are here to develop partnerships with equipment producers that help ensure your machinery operates efficiently with a high-performance solution like Thermelt®.

- Global sourcing: As mentioned above, through our parent company Arkema, we are vertically integrated to provide Thermelt® low pressure molding technologies at a global scale.

Are you interested in a solution that combines flexibility, reliable adhesion and UV resistance into one formulation for electronics encapsulation? Contact a Bostik expert to learn how Thermelt® 964 can help you.

Other Relevant Content:

Low Pressure Molding Adhesives

Thermelt® Bostik’s Bio-Based, Low Pressure Molding Polyamides

Overcome Manufacturing Challenges with Low Pressure Molding Adhesives

Meet Your Goals with the Right Low Pressure Molding (LPM) Method

Why Polyamide Adhesives in Low Pressure Molding Are Revolutionizing Electronics Protection

©2025 Bostik, Inc. All Rights Reserved

All information contained herein is believed to be accurate as of the date of publication, is provided “as-is” and is subject to change without notice. To review our full U.S. Legal Disclaimer, visit: https://bostik.com/us/en_US/legal-disclaimer

Thermelt® is a trademark of Arkema Group.