Some facade panel adhesive systems require as many as ten to fourteen steps during application. Bostik Paneltack® delivers reliable bonding in just five straightforward steps. This is largely because Bostik primers and adhesives combine essential properties. Take the wash primer. It does it all: degreases, cleans and endhances adhesion in one step. As a result, applicators only need to follow five clear steps, saving valuable processing time without compromising on quality, durability, or reliability.

Matched to the panel specifications

There is no single universal adhesive for bonding facade panels.

Panel properties such as dimensions, weight, expansion and shrinkage, as well as environmental conditions like sun and wind exposure or potential seismic risks, require carefully tailored adhesive/primer combinations. This is, for example, important to eliminate the risk of panels detaching over time.

Bostik has been addressing this for over 35 years with the Paneltack® system, offering specific adhesive/primer combinations for the reliable, safe, and fast bonding of Rockpanel panels, HPL/solid-core panels (including Trespa and Fundermax), and thin ceramic panels (including Laminam, Grespania Coverlam, and Cosentino Dekton).

In addition, the Paneltack® system is certified for bonding fibre cement panels such as Swisspearl.

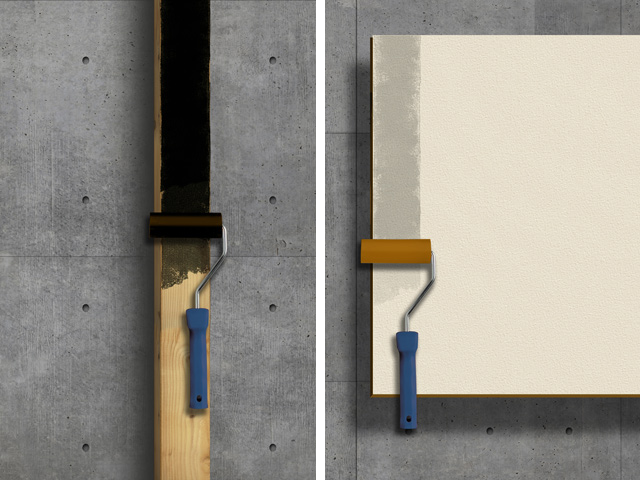

The panels can then be bonded in just five simple steps.

Advantages of bonding facade panels vs. screwing

- Endless design possibilities

- Durability and good thermal insulation

- Quick and clean installation

- Significantly better distribution of tension

- No visible screws or cover caps

- No contamination from leak marks

- No point load, preventing breakage

- Suitable to install thinner panels

Work smarter, reduces mistakes by choosing PanelTack

Paneltack® is not only a highly reliable system for bonding facade panels, it is also fast. Additional steps that are often required with other systems, such as cleaning, drying, and sanding, are in most cases not necessary with Paneltack®.

Since all products are single-component, there is no need to mix any ingredients. This not only saves valuable labor time but also eliminates errors caused by incorrect mixing ratios or techniques. Furthermore, leftover material does not need to be discarded at the end of the day; when properly sealed, the product is ready for use again the next day.

With more than 35 years of experience, four R&D departments, our own production department, extensive certifications, close collaborations with panel suppliers and comprehensive processing instructions, processors and their end customers can rely on the highest quality, durability and reliability.

With more than 35 years of experience, four R&D departments worldwide, in-house production, extensive certifications*, close partnerships with all panel suppliers and comprehensive processing instructions, processors and their end customers can rely on the highest quality, durability and reliability.

*Certifications: ETAs for the bonding of various panels, KOMO, Reaction to Fire according to EN13501-1 and VOC certifications such as A+, EC1 Plus, M1 and ISEGA. An EPD (Environmental Product Declaration is also available for all Bostik Paneltack adhesives.)