The key benefits of passive fire protection

The passive fire protect range contributes to the structural stability of a building and provide time for the occupants to evacuate safely. Extinguishers have more time to take action and fight the fire, as passive fire resistance limits the spread of flames and smoke, thus reducing the transfer and flashover of fire between compartments.- Saving lives: passive fire protection measures are specifically designed to protect lives, minimizing the risk of harm to occupants during fire incidents.

- Limiting material damage: effective PFP applied within buildings significantly reduces material damage loss, safeguarding valuable assets and minimizing financial impacts.

- Minimizing business losses: by ensuring safety and preserving property, PFP measures help businesses reduce losses and maintain operational continuity.

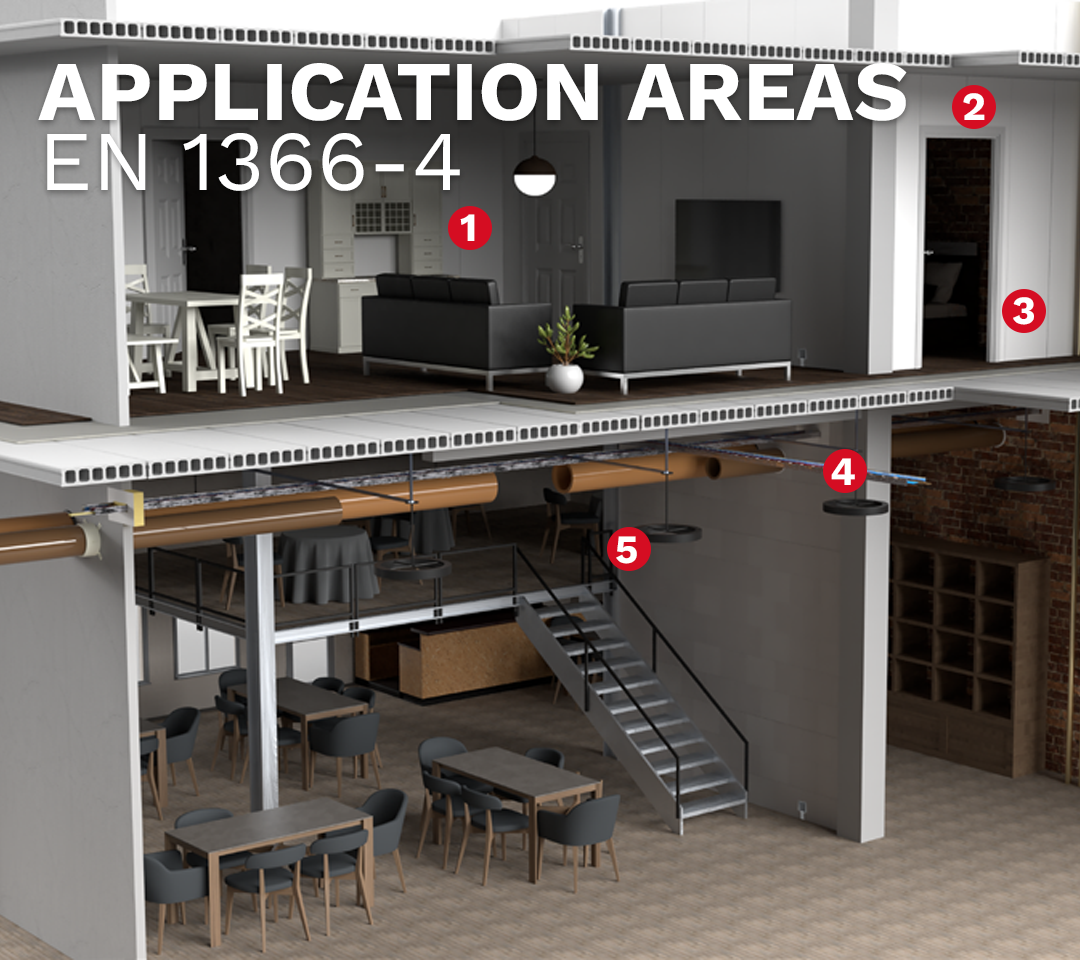

Passive fire protection for linear joints

Within a fire compartment, consisting of fire-resistant walls and floors, the completion of the compartment involves the application of sound fire-resistant seals to joints between these structural elements. The fire resistance of our PFP solutions, designed to seal these linear joints effectively, has been rigorously tested in accordance with European Norm 1366-4. These tests, conducted by certified laboratories (notified bodies), encompass different surface types and multiple joint widths.

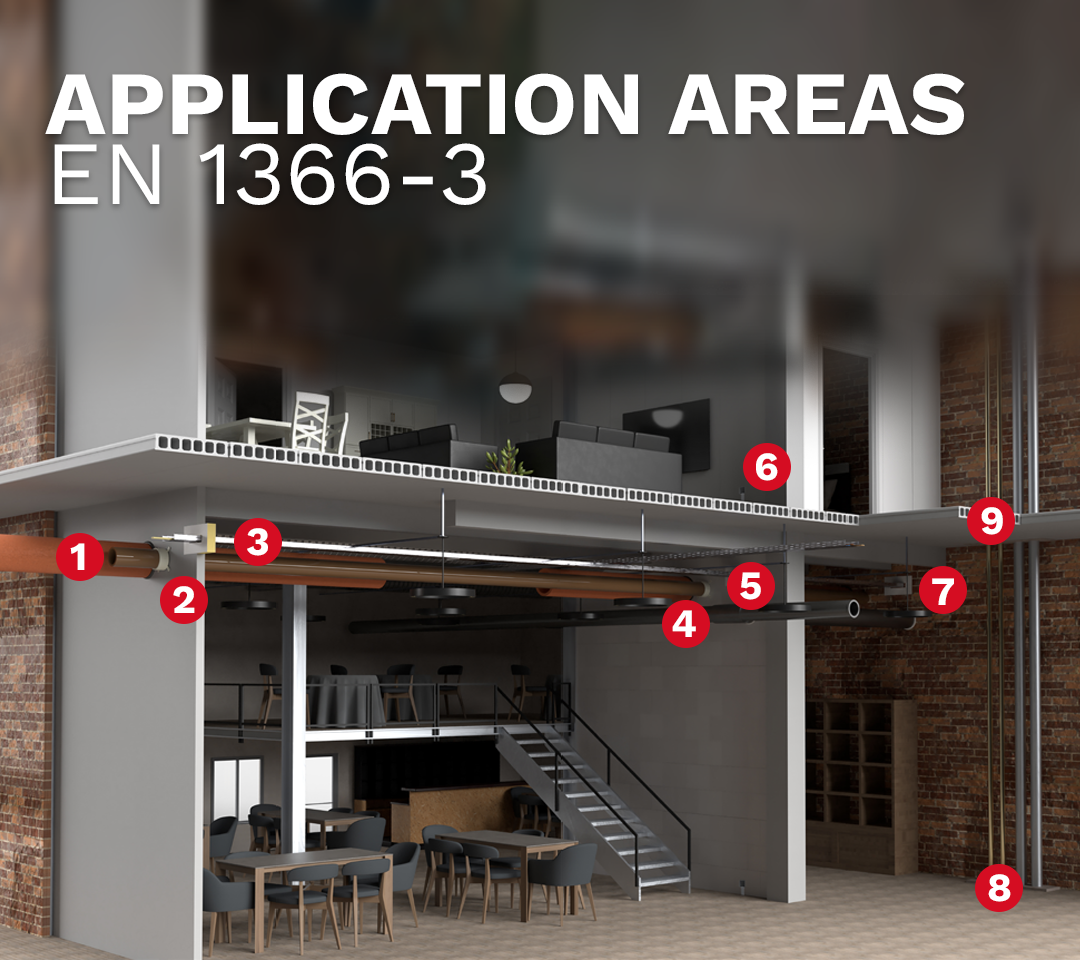

Passive fire protection for service penetrations

The fire compartment consists of fire resistant walls and floors. These walls and floors have openings through which pipes and electricity cables are transmitted. A fire compartment is not complete until these openings have been sealed safely with the correct materials. The products below have been tested in accordance with 1366-3.

Choose Bostik Fire Protect

To strengthen passive fire protection, automatic fire detection systems and sprinkler installations can be implemented in conjunction with other PFP measures. Intumescent coatings and fire-resistant barriers (such as doors) are integral elements of our complete PFP range. By using these solutions, you take action to ensure the highest level of safety for occupants and protect property from the devastating effects of fire.Involve Bostik's PFP range for reliable passive fire protection solutions. Our commitment to safety and expertise in this field will give you peace of mind, knowing that your building and its occupants are well-protected.

CE Classification (Europe)

In today’s world globalization and harmonization have become common and familiar terms. This is also true at building standards and regulations. Within Bostik we embrace this movement and strive for a globalized standard which provides transparency and simplicity in sealing and bonding.

UL-EU

The UL-EU Mark is a voluntary pan-European certification Mark of Underwriters Laboratories for all products where an EN standard exists. UL-EU Mark is intended for use on products destined for the European marketplace. It means that UL has evaluated representative samples of a product or component and determined that those samples comply with the UL-EU Mark service requirements.

GEV-EMICODE® EC1 Plus

EMICODE® is a protected product classification system and at the same time an Eco label. Installation materials, adhesives and construction materials are submitted to a strict certification procedure where the quantity of emitted volatile organic compounds (VOC) is examined. When products come with the EC1 Plus certification, they can be easily adapted in the BREAAM and LEED schemes.

M1 Certification

Various chemicals are emitted from building and interior decoration materials into indoor air. The classification presents emission requirements for the building materials, fixtures and furniture, with and without padding or textile coverings used in ordinary work spaces and residences with respect to good indoor air quality. M1 stands for low emissions.

A+ Certification

A+ is a compulsory French VOC emissions labelling of construction products installed indoors, based on emission testing. This regulation foresees that any covered product placed on the market has to be labelled with emission classes based on their emissions after 28 days, as tested with ISO 16000 and calculated for European reference room. The same holds true for EMICODE, GUT and Blue Angel. Also other valid information can be used as a basis for this assignment of class, such as tests based on ISO 16000, but with shorter testing duration.

ETA

The European Technical Assessment (ETA) is documented assessment of the performance of a construction product, in relation to its essential characteristics. This is the definition given by the Construction Products Regulation (CPR, Regulation (EU) No 305/2011), which governs the marketing of construction products in the European Economic Area. The ETA provides manufacturers with a voluntary way for CE marking their innovative non-standard construction product and thus bringing it to the European internal market. As an independent assessment, the ETA also contributes to createtrust in the performance of the construction product related to its essential characteristics and taking into account its intended use(s). An ETA can be issued for construction products, if:

- they are not or not fully covered by any harmonized European Standard (hEN) and

- the assessment methods and criteria have been laid down in a European Assessment Document (EAD).

The European Assessment Document (EAD) thus forms the basis for the European Technical Assessment. It contains the methods for assessing the product as well as specifications on the system for assessment and verification of constancy of performance (AVCP system) to be used. If the product in question is not yet (completely) covered by an existing EAD, EOTA will develop a new, or adapt an existing, European Assessment Document. The ETA is valid in all EU Member States and those of the European Economic Area, as well as in Switzerland and Turkey. But it is also often accepted as technical documentation in other parts of the world. ETAs issued after the 1 July 2013, i.e. European Technical Assessments, are valid for an indefinite period of time.

DECLARATION OF PERFORMANCE

The ETA is the basis for a Declaration of Performance (DoP) which the manufacturer is required to draw up in accordance with the Construction Products Regulation (CPR) before CE-marking his product. The CE marking allows the manufacturer to freely market his product on the European internal market. By affixing the CE marking to the product, the manufacturer confirms that his product is in line with the applicable EU legislation and takes responsibility for the conformity of this product with the declared performance.Sign up for technical training

Bostik ACADEMY is a knowledge center carefully created for professionals in the construction market. At the ACADEMY you can sign up for a tailored training program, matched to your needs and skills.

Our experienced Technical Team will present our product portfolio, best application methods, and key industry recommendations. Sign up through the link below to learn more.