The Evolution of Core Designs

Diapers and the disposable hygiene industry have come a long way since 1949. That is when the first disposable baby was marketed by CHUX (now Johnson & Johnson). In 1984, Kimberly Clark introduced adult diapers, opening up a whole new market. And as for feminine hygiene … Would it surprise you to learn the first disposable pad for women, Lister Towels, hit the market way back in 18961?

As they evolved, disposable hygiene products transformed how people live their daily lives in a multitude of ways. Now, as manufacturers explore and experiment with new disposable hygiene core designs, the future for these products is even more exciting.

Early diaper designs

The initial disposable diapers were quite simple—yet still considered luxurious. The core was a stack of 15 to 25 sheets of tissue paper. They could hold an estimated 100 ml of fluid, which meant they needed to be changed after every use. Plus, they did not have the features we see today. (Elasticised waistbands, leg cuffs, re-fastenable ear tabs, and wetness indicators all came later.)

Even so, parents came to love disposable diapers, and the popularity of the product grew. Competition among manufacturers increased as well. Just one year after the original tissue-core diaper was released, Paulistrom introduced the first fluff core, made of cellulose wadding. It was cut, sized, and put in reusable panties to help with fluid absorption and distribution, as well as improved performance.

The introduction of superabsorbent polymer (SAP)

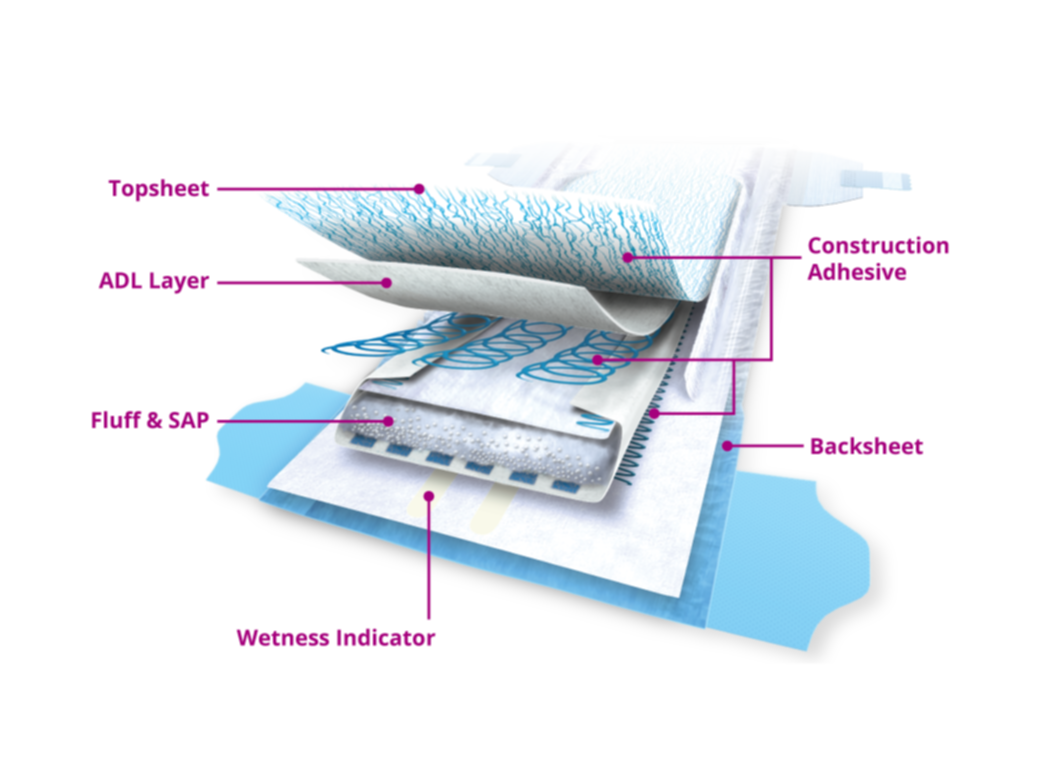

Disposable hygiene made another big leap in the 1980s when Unicharm introduced superabsorbent baby diapers in Japan. Compared to an all-fluff core, superabsorbent polymer (SAP) could hold greater volumes of fluid, even under pressure. But SAP alone tends to absorb and wick fluid slowly, so fluff had to stay to provide absorption speed and wicking. To continue increasing absorption, manufacturers began to add greater amounts of SAP to the fluff in the core matrix.

Variations in the traditional core

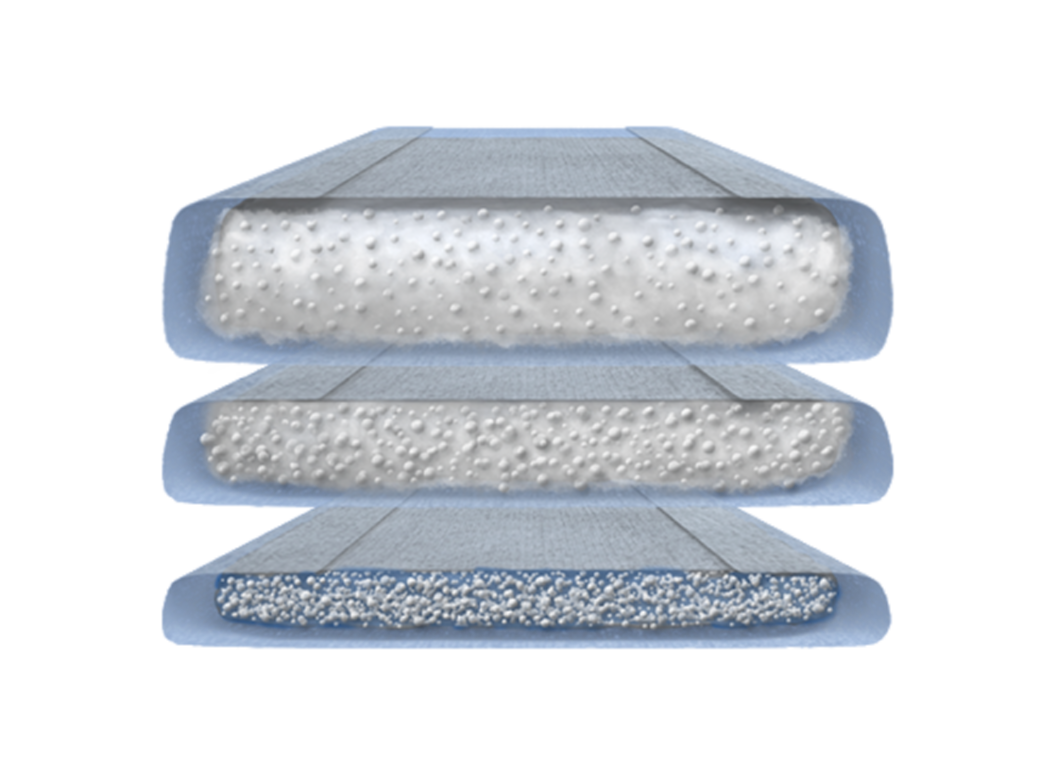

Today we see a variety of core designs and fluff-to-SAP ratios used by manufacturers across the globe. In traditional style cores, fluff-to-SAP ratios typically range between 30% SAP/70% fluff and 70% SAP/30% fluff.

- In cores with up to 50% SAP, the fluff fibres are entangled to create a pad that keeps the SAP in place and supports core integrity. To improve the core’s integrity even more, a core wrap can be used. This wrap surrounds the fluff/SAP and is sealed with a core adhesive.

- When the ratio of SAP to fluff increases, manufacturers find themselves facing additional challenges. At 70% SAP/30% fluff, a core wrap and a core adhesive are both needed to prevent the loss of SAP powder. But there is another issue: the loose SAP within needs further support. Using Bostik’s Conditioned Core Integrity Test, we have seen that a core at 70% SAP will immediately fail if a core integrity adhesive is not used.

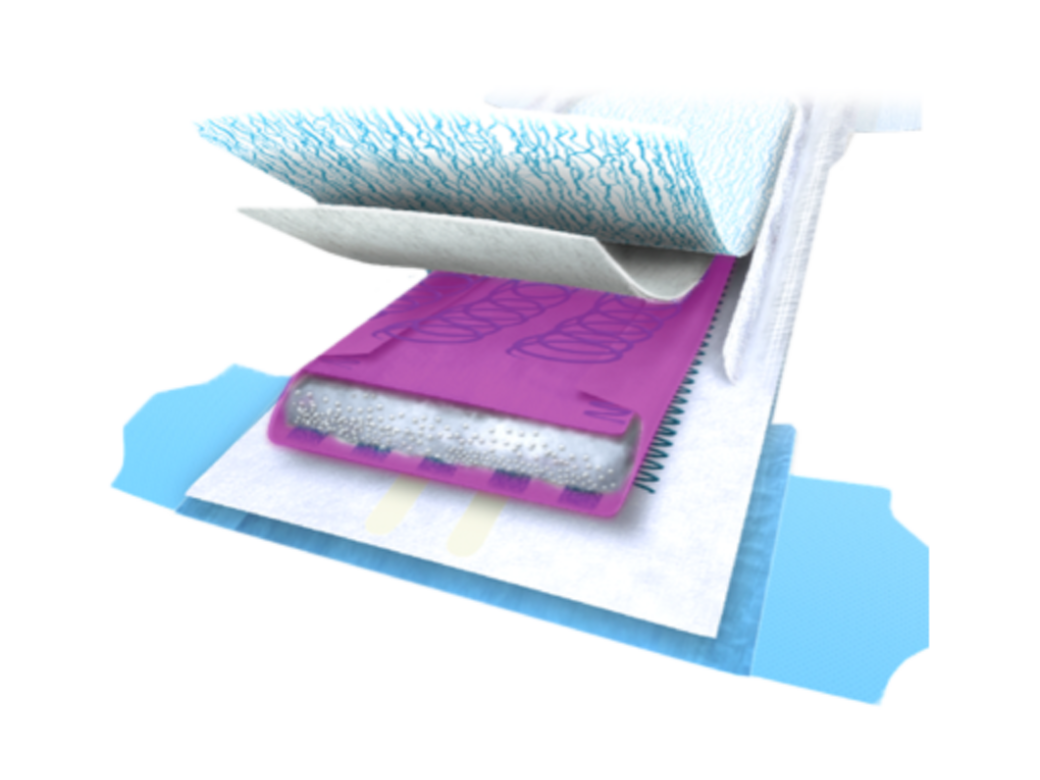

Newer innovations for reduced and zero fluff

As product producers look toward reducing the thickness of their cores, fluff-free cores may be an option. However, without the fluff, there are no cellulose fibres to hold the SAP powder in place. Even incorporating new SAP that has better wicking and absorption speed, a core adhesive is needed to avoid cracking.

The compound core, which typically consists of multiple layers of nonwoven or tissue with SAP, is one alternative. (When made offline, it is called a pre-compound core.) Another is the channel core, which features channels free of absorbent material. Some producers include fluff in their channel core designs. Others do not.

Choosing the right adhesive for your core

If you are looking to explore new core options, we strongly recommend involving Bostik’s core adhesive experts in the early stages of development. With our expertise, we can help you quickly identify the nonwoven adhesive solutions that best meet your design needs.

Request a meeting today!

1Jennifer Kotler, PhD, “A Short History of Modern Menstrual Products,’ Helloclue.com