Doing More With Less: Adhesive’s Role in Core

Manufacturing thinner absorbent hygiene products without sacrificing performance is a long-standing market trend. Other innovations relate to sustainability, new core designs, and enhanced performance. How can these be accomplished? The answer is with adhesives.

For 21st-century core designs, adhesives take on a bigger role and add more value. Specific adhesives are formulated to meet the needs of absorbent hygiene product manufacturers.

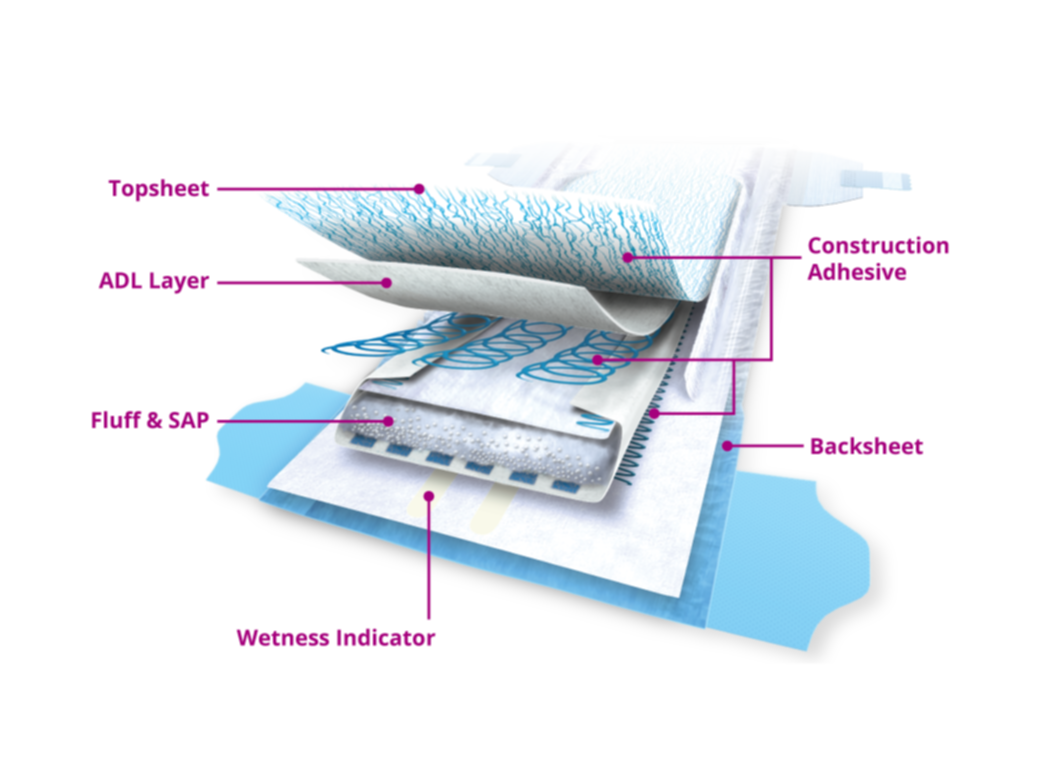

In traditional cores, the adhesives:

- Help prevent core shifting

- Hold the acquisition distribution layer (ADL) in place

- Stabilise the fluff/SAP (or SAP only) core matrix

- Seal the core wrap (if one is used)

- Bond materials to prevent shifting

Together, these tasks support core integrity and performance, which helps enable full absorption and rewet protection. Regardless of core design, the result is improved comfort, protection, and skin health for the wearer.

All components of the core add value, and adhesives are no exception. Knowing how and where to use the right adhesives can impact overall core integrity and performance. Particular points to consider when building a traditional core include:

Adhesive Placement — Adhesive applied to the top of the core can slow down liquid absorption into the core. Applying adhesive to the bottom of the core instead can improve durability and speed up absorption.

Add-on Level — Different add-on levels may be required based on application method and substrates. The function of the adhesive in the product and product expectations must also be considered. Testing can be invaluable, though the specific protocols used may impact results.

Adhesive’s Role in Channel and Compound/Pre-compound Cores

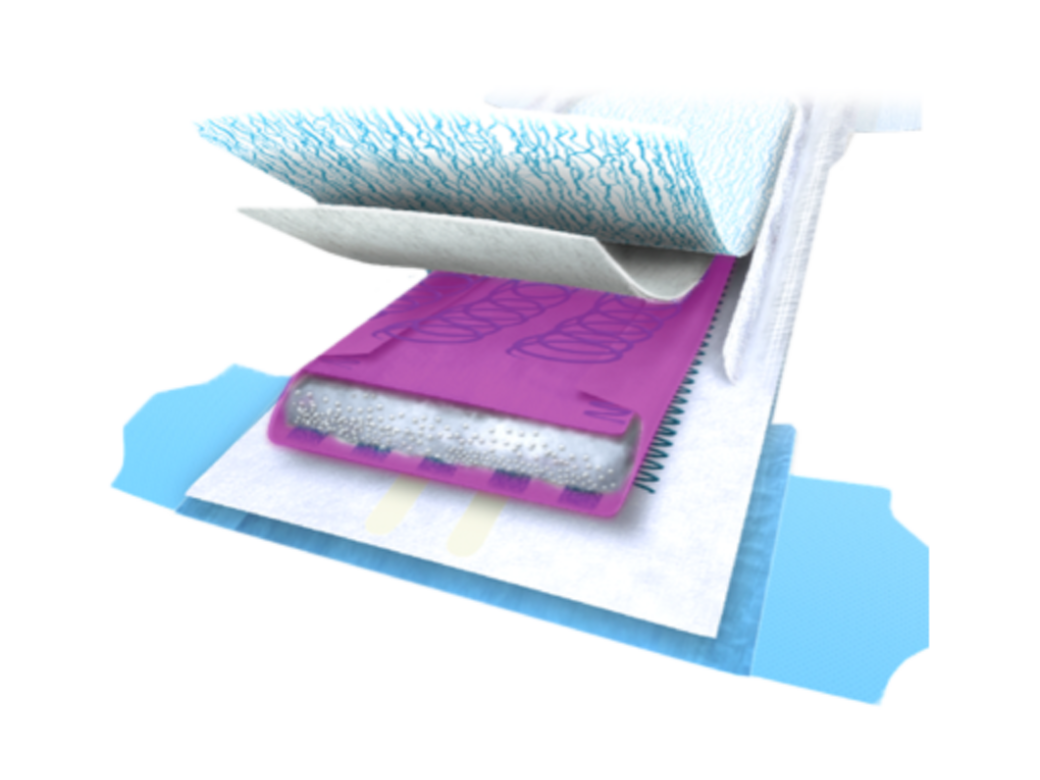

The channel core is a newer design that can provide a thinner profile and comfortable fit. Adhesive is used to bond the top and bottom layers, creating channels between the absorbent core materials. In some designs, the channels are intended to hold as the SAP swells; in others, they are intended to release. Specially formulated adhesives may be required to help ensure the preferred outcome.

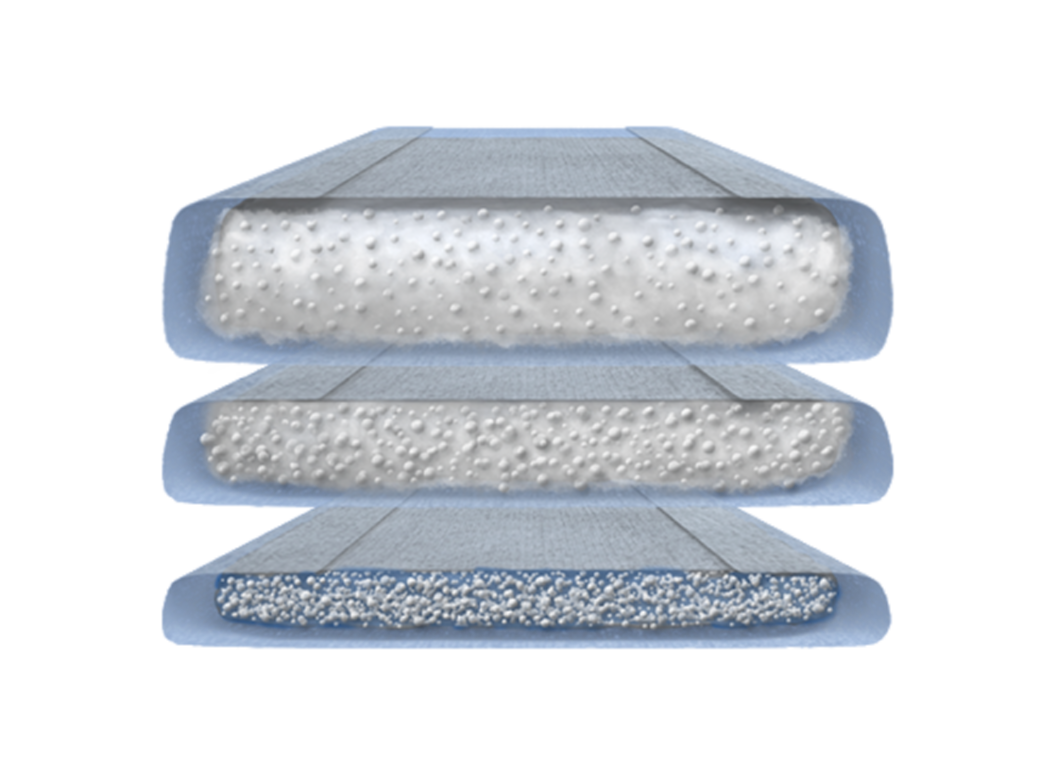

In compound and pre-compound cores, the centre layer is a fluffy nonwoven combined with SAP powder. This composite is bonded with adhesive to a top and bottom layer of tissue or nonwoven. Adhesives are used to stabilise the SAP both in production and in use.

Today’s many types of absorbent hygiene cores are complex and intricate systems. That is why it is helpful to seek the assistance of core experts early in the process. Bostik has extensive knowledge of both absorbent hygiene products and the adhesives they use.

Additional value you can rely on with Bostik’s core adhesives

The benefits of our adhesive solutions don’t stop with a functional core; they also support you in other ways. Reinforcing core stability and function helps you maintain consumer satisfaction. Features such as easy clean-up and thermal stability assist with operational efficiencies and improved profitability. Your choice of a Bostik core adhesive can even aid you in advancing your goals for social responsibility.

If you are considering making changes to your current product designs or adhesives, consult with the experts at Bostik. We can guide you in selecting the right adhesives for your products and goals as you explore changes to remain competitive in the marketplace. Request a meeting today.

CODE: CO-22A10; APP-22A04