Operational Efficiency At a Glance

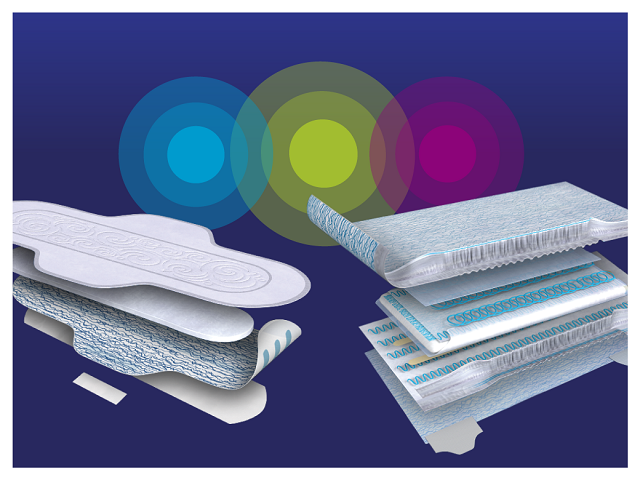

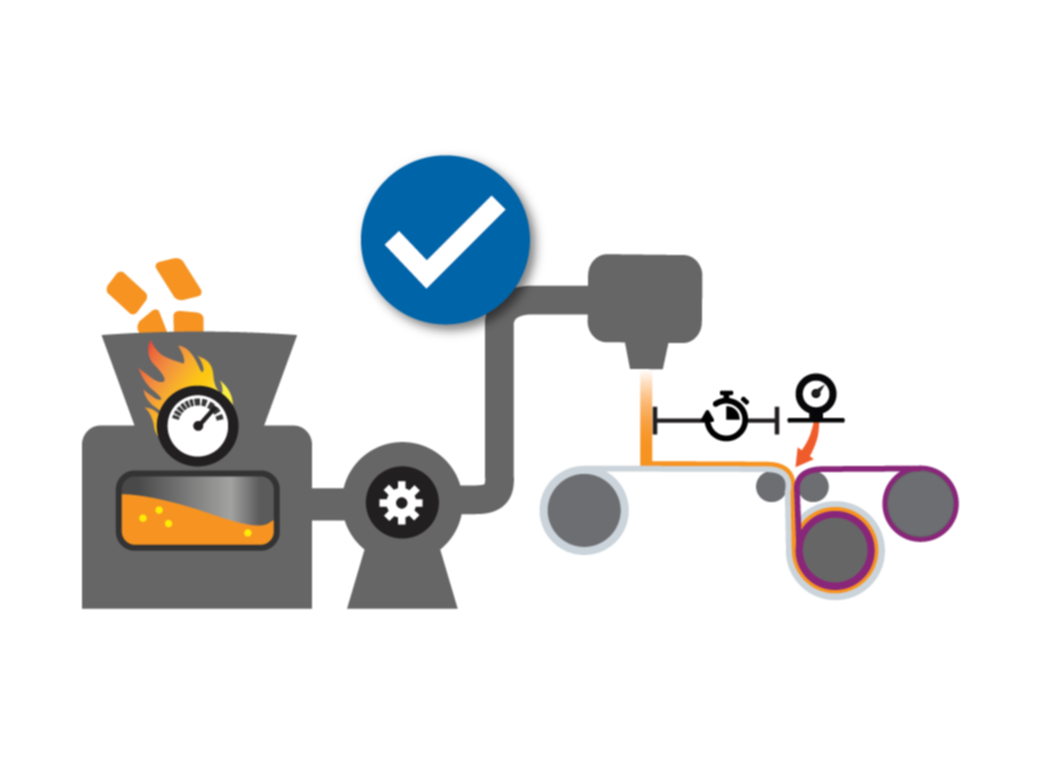

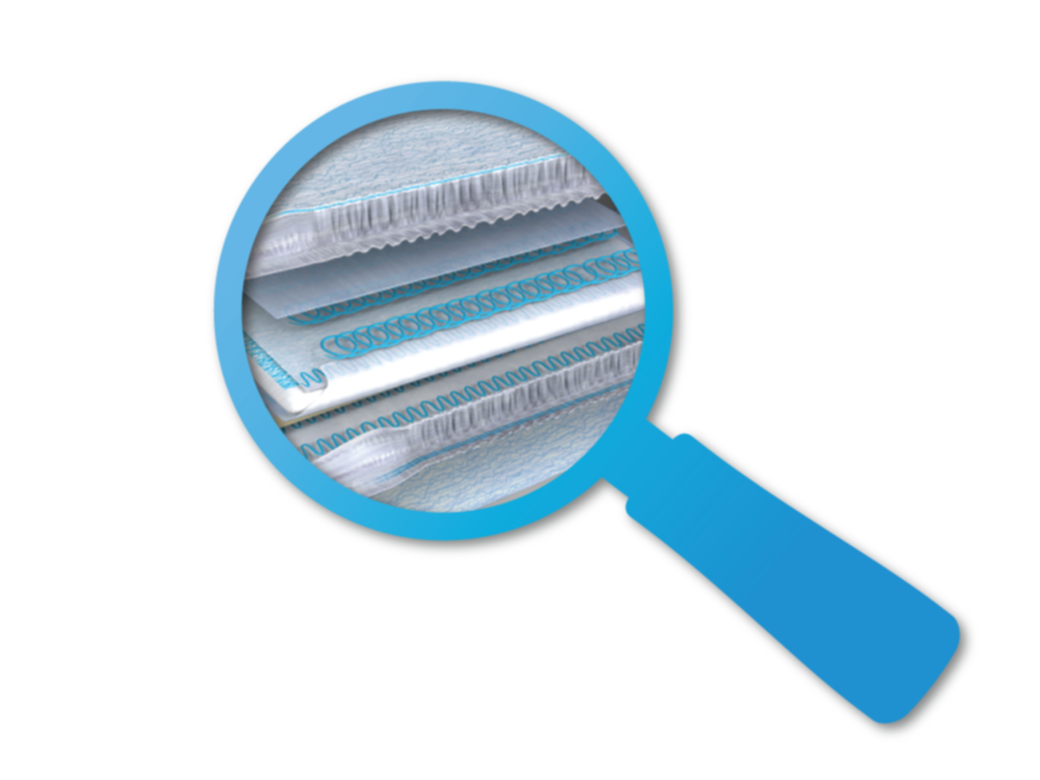

Adhesives play an integral part in optimising product designs for your absorbent hygiene products. The right adhesive choices can also support efficient manufacturing operations—one of the four main elements of our Connected Product Line. Attributes to consider when making your selection include:

-

A wide application temperature window enables the use of a broader range of substrates and increases the tolerance to temperature variability

-

Minimal bleedthrough on application eliminates build-up and reduces the need for unexpected clean-ups and associated downtime

-

Adaptability and performance across a range of nozzles so the same adhesive can be used across differing line configurations

-

Tolerant open time ensures the adhesive works with a variety of production configurations with minimal adjustments

-

Rapid adaptability to the widest range of substrates for faster, more efficient line changes

-

Good thermal stability minimises charring to reduce downtime for filter and nozzle cleaning

-

A wide processability window provides greater tolerance to small changes in application conditions

An adhesive that is easy to work with can help maximise operational efficiency, boosting productivity and your bottom line. It can also enable improved profitability, consumer confidence, and social responsibility. Considering all four areas of impact allows article producers like you to make informed decisions regarding adhesive selection for each use in your absorbent hygiene products.

Learn more about the attributes for operational efficiency that apply to each adhesive application: construction, elastic attachment, core, pad attachment, and hot-melt wetness indicators.

CODE: CPL-22A11