A Closer Look at Fluff-Free Core Designs in Disposable Hygiene

Are you considering fluff-free options for your hygiene product designs? Other disposable hygiene manufacturers might just be doing the same. According to our experts, the shift is driven by a number of trends. Whether for comfort or discretion, some consumers prefer thinner products. Manufacturers value their stronger core integrity. Also, going fluff-free typically uses fewer raw materials and can improve production and sourcing efficiencies. These can appeal to the sustainability-minded consumer or producer.

In fluff-free cores, the role of fluff needs to be met by other means. Tasks include:

- Wicking moisture quickly to the SAP (superabsorbent polymer)

- Helping to keep the SAP powder in place during production and in shipping

- Stabilising the SAP after insult when it is the heaviest and prone to cracking and clumping

Compound and pre-compound cores use a high-loft nonwoven

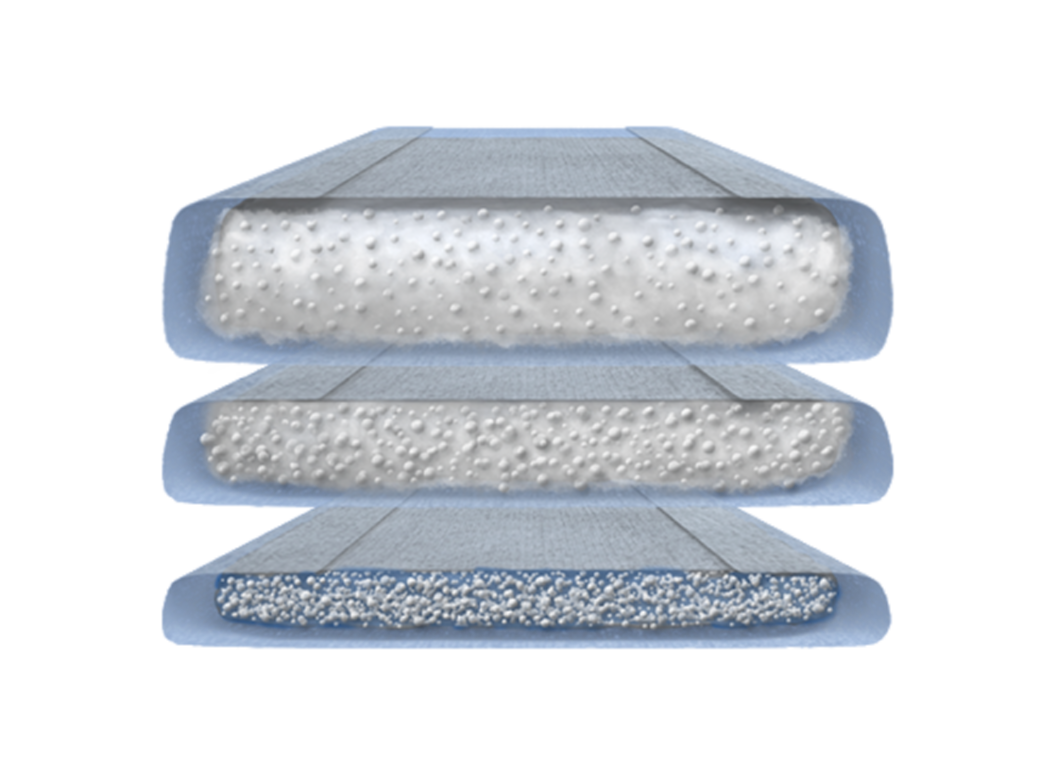

One viable option for going fluff-free is the compound core. These cores can be either manufactured in-line or provided to the article manufacturer pre-produced. Both are made by layering SAP within absorbent top/back layers and high loft synthetic nonwoven fabric. To help hold the layers together and to stabilise the SAP particles, an adhesive is used. This is especially helpful for the pre-compound variety, which is manufactured offline and then shipped in boxes or rolls to the production line.

The primary advantages attributed to the compound/pre-compound core are:

- Thinner profile

- Excellent integrity when wet

- Simplified production due to being fluff-free

There can also be disadvantages. Compound and pre-compound cores tend to have reduced wicking ability. And, with insufficient or improper application of adhesive, they may suffer from SAP loss or uncomfortable shifting of the heavier SAP after insult. However, with the improvement of top layers, the wicking could be significantly increased. Meanwhile, with the help of proper adhesive and designs, the SAP could be well bonded in place.

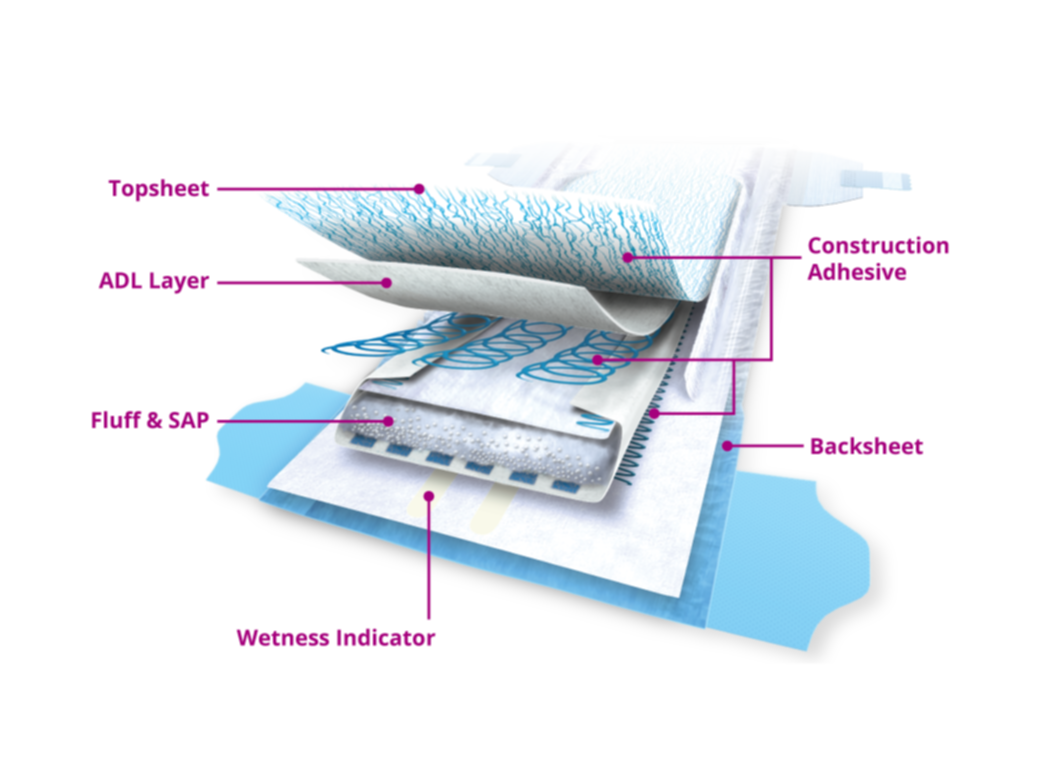

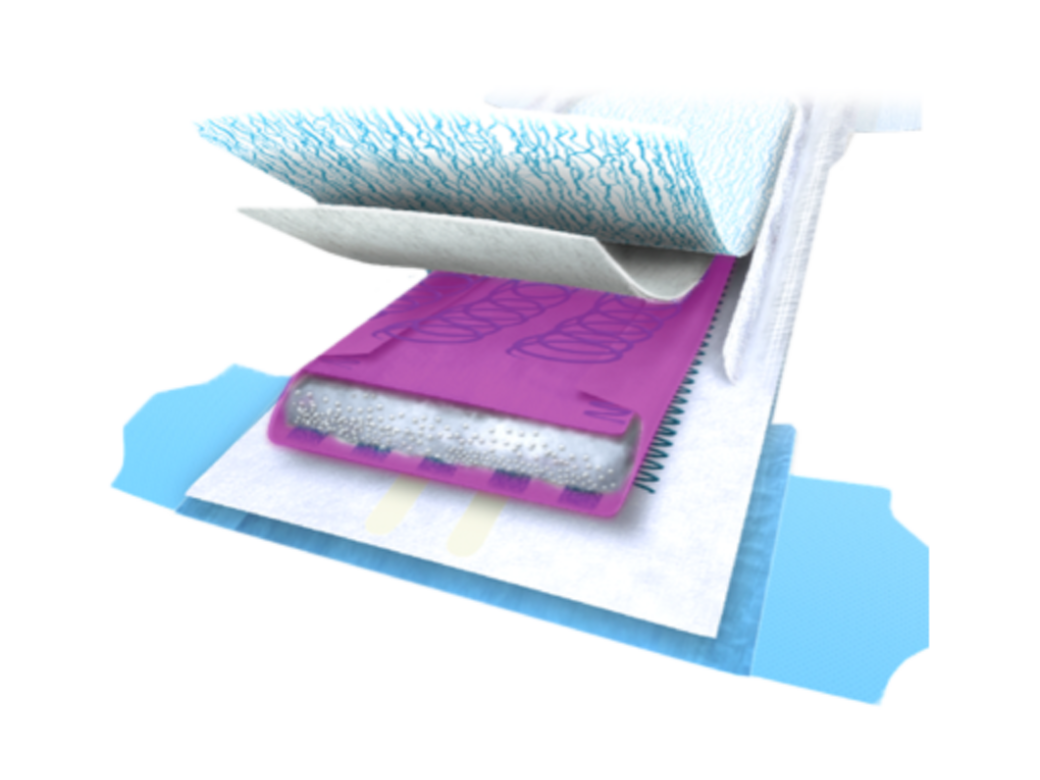

Adhesive helps create fluff-free zones in the channel core

Another design for going fluff-free is the channel core. The name comes from longitudinal zones (channels) that are free of any absorbent material. These channels are formed by bonding the upper and lower core wrap materials together with adhesive. It also requires adhesive to hold the SAP in place.

Benefits attributed to the channel core include:

- Better core integrity and reduced risk of core cracking

- Better fluid circulation for better core utilisation

- Better air circulation for improved dryness and skin wellness

- Less bulking and sagging

We have seen variations in design. They may differ in the number, shape, and positioning of channels. Some cores are designed to release upon insult. Others are intended to stay intact. Disadvantages can include uncomfortable shifting of the SAP or poor bonding of layers if the adhesives are not properly chosen or applied. In addition, if a suitable channel adhesive is not used, it may release unexpectedly as the SAP swells after absorbing the insult.

Are you considering a shift to fluff-free designs? Bring Bostik into the conversation early. We can help you determine what will work best to satisfy your consumer and achieve your product’s intended performance.

Ready to talk?

Get in touch with a Bostik core expert.