Terminology for Bonding Solutions in Disposable Hygiene

Access a printer-friendly PDF version here.

Absorbency: The ability of a material, such as fluff and superabsorbent polymer (SAP) in a disposable hygiene core, to absorb and hold liquid within its structure.

Additives: Components added to give a product specific properties. Examples of additives in adhesives include antioxidants, pigments and dyes, fluorescing agents, and UV absorbers.

Add-on level: The amount of adhesive per unit of surface applied to a substrate. See Coating weight.

Adhesion: The state of two material surfaces that, when brought together, are difficult to separate because they hold together with interfacial forces. Adhesion can arise from a variety of phenomena depending on the type of interfacial forces. In the context of adhesives, physical adhesion and dispersive adhesion are common. Mechanical adhesion, long thought to be the only type of adhesion, occurs with porous surfaces such as wood or the nonwovens used in disposable hygiene products. In the latter case, hot melt adhesive penetrates the pores and solidifies, adhering to the nonwoven. Dispersive adhesion is an actual attraction which occurs on smooth surfaces, such as metal or the polyethylene films used in certain disposable hygiene articles. This attraction is the result of weak interfacial forces (Van der Waals). In the case of ultrasonic bonding, the two substrates are partially melted at their point of contact, becoming a single piece, so we are beyond the definition of adhesion.

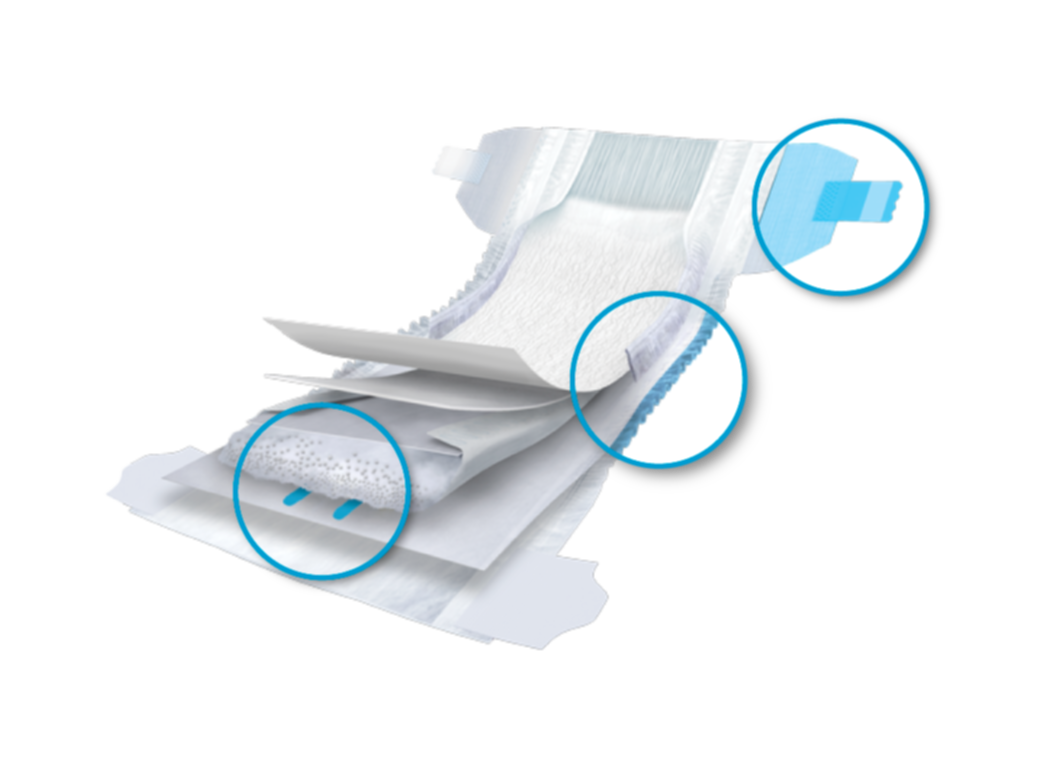

Adhesive: A material, often synthetic, used to assemble two or more components together through the phenomenon of adhesion. Categories of adhesives include hot melt adhesives, water-based adhesives, solvent-based adhesives, and reactive adhesives. Adhesives play a variety of roles in the manufacturing of disposable hygiene products and they may be formulated with specific properties to suit their intended uses, such as construction adhesives or elastic attachment adhesives.

Amorphous poly-alpha-olefins (APAO): A type of polyolefin that has limited or no true structure order to the molecular backbone structure, thus the term amorphous. Conversely, a more orderly structure is referred to as crystalline.

Antioxidant (AO): An additive that helps prevent oxidation of the various components in the adhesive to avoid degradation by the oxygen present in the air.

Application temperature: The temperature at which a hot melt adhesive is applied effectively.

Applied forces: Any forces, such as pressure, twist, bend, or stretch, applied to an object at rest. Selecting and/or designing an adhesive requires determining how it should react to various applied forces. For example, an elastic adhesive would need to hold the elastic in place while it stretches and retracts. An ear attachment adhesive must resist shear forces that occur during daily activities.

Aromatic: Outside of chemistry, aromatic often describes a material that has a pleasant smell. But in organic chemistry, aromatic refers to cyclic hydrocarbons that have a very specific electronic structure which makes them very stable. Legend has it that they were named aromatic because when this chemical structure was discovered, a number of these molecules tended to have a distinct smell. However, this is not true of all chemicals which chemistry would class as aromatic today.

Bio-based: Derived from biomass. Biomass may have undergone physical, chemical, or biological treatment(s). The use of bio-based substrates can affect bonding choice. Certain bio-based fibres, when present at a higher percentage, reduce thermoplasticity and the ability for the material to melt in order to bond using certain methods.

Bleedthrough: Describes an adhesive passing through a substrate and may be caused by heavy add-on, low viscosity, or high compression. Bleedthrough can result in adhesive contaminating processing machinery and requiring cleanup. If the excess adhesive seeps into other areas of the product where it was not intended, it can also affect the quality of the product, such as product blocking or leg gathers not standing up when opening the diaper.

Changeover: Converting a production line from one configuration to another. This can range from changing one component, such as a substrate or adhesive, to producing a different product entirely. An adhesive changeover generally does not require a reconfiguration of the assembly line.

Char: To partially burn a substance and blacken its surface, or the blackened portion of that substance. It is the final stage of high temperature or oxidative degradation. Bostik tests its adhesives for overall thermal stability.

Coating weight: The amount of adhesive per unit of surface applied on a substrate. Also known as “add-on level,” coating weight is an important variable for optimising bond performance and cost. Excessive add-on can cause bleedthrough, product blocking, or build-up on equipment. Coating weight is typically measured as grams per square metre, i.e. g/m² or gsm. For elastic attachment adhesives, the coating weight may also be given by unit length, such as grams or milligrams per linear metre.

COATS: An acronym used by Bostik for 5 critical process parameters: Compression, Open time, Add-on level, Temperature, and Substrate. COATS is an important method of optimising adhesive processing on a customer’s production line.

Cohesion: The tendency of molecules within a material to “hold together” and make the material stronger due to intermolecular forces. Cohesion gives an adhesive its internal strength. Cohesion helps ensure that the adhesive does not lose its integrity when a force is applied; adhesion, on the other hand, helps ensure that the adhesive does not separate from the substrates and involves interfacial forces.

Compression: The amount of force used to bring intimate contact between substrates and adhesive to ensure adhesion. Fine tuning compression is critical. Higher compression can improve bond strength, but may also damage the substrate, cause bleedthrough, or roll wear.

Conditioned core cracking test: A test method developed by Bostik to evaluate core integrity. Bostik includes a preconditioned component to the test procedure to simulate real-life conditions to better evaluate core integrity.

Construction adhesive: In disposable hygiene products, construction adhesives are used to bond films and nonwovens together to attach the different layers of an article. Manufacturers should generally look for construction adhesives that demonstrate excellent peel and/or shear strength. These properties can retain the integrity of the article during use.

Copolymer: A polymer obtained by polymerising two or more different co-monomers. They can be designated as random or block. In a random copolymer the monomers are present in random order on the polymer chain (A-B-A-A-B-A-B-B-A). In a block copolymer the monomers are sequentially polymerised (A-A-A-A-B-B-B-B-A-A-A-A).

Core cracking: A failure outcome of poor core integrity. Core cracking is a separation in the core of a disposable hygiene product due to gravity, movement, and/or the weight of the absorbed liquid. When the core has cracked, additional liquid voided on the core may “fall through the cracks,” allowing it to leak out without being absorbed. To evaluate core cracking, Bostik uses the conditioned core cracking test.

Core integrity adhesive: A core integrity adhesive may be used to improve the integrity of the core in multiple ways. This includes helping to stabilise the fluff/SAP matrix, prevent shifting, and withstand core cracking during consumer use. A cracked core at any stage of use can result in poor absorption and ultimately leakage.

Corona treatment: A high frequency discharge applied to the top surface of plastic films, foils, or paper in order to increase their surface energy. This allows better wettability and adhesion of inks, coatings, and adhesives.

Creep: The slow movement of a material under stress. Creep performance is important for elastic attachment adhesives, which must hold the elastic in place firmly while the elastic stretches and retracts.

Crystallinity: Depending on their molecular structure, polymer chains, or at least a certain portion of the polymer chains, can align in a very orderly structure that likens that of a mineral crystal. This is the “crystalline” structure. The rest of the molecules are tangled in a random structure that is called “amorphous.” The fraction of ordered molecules in a polymer is its degree of crystallinity. The degree of crystallinity can affect an adhesive’s performance.

Cut off: The termination of a hot melt adhesive application. As the production line moves, a nozzle applying the hot melt adhesive must start and stop cleanly. Improper cutoff can cause adhesive to deposit where it is not intended, whether in the garment or on the machinery itself, leading to a variety of unwanted outcomes.

Debond: To detach two substrates which have been successfully bonded together.

Degradation: Undesirable changes in the mechanical, bonding, or aesthetic properties of an adhesive. Degradation is usually caused by exposure to atmospheric oxygen or UV light. Extreme temperatures, shear, and residual catalysts can also cause degradation.

Differential scanning calorimetry (DSC): Measures the heat flow into and out of a material while it is being heated at a specific rate. Specifically, it determines properties such as heat capacity and transition temperatures.

Dispersive adhesion: A type of adhesion that “attracts” the surface of a substrate to the adhesive through weak intermolecular forces called van der Waals. This can explain how hot melt adhesives adhere to surfaces such as polyethylene films used in certain disposable hygiene products.

Elastic attachment adhesive: They are typically used to attach elastic strands and films in high stress applications such as elastic waist bands and leg cuffs. The powerful creep resistance performance and excellent shear strength of an elastic attachment adhesive holds the elastics in place to support consumer confidence in leakage protection, fit, and discretion. The use of elastic strands and films plays an integral role in today’s diaper designs

Elasticity: The ability of an object or material to resume its normal shape after being stretched or compressed.

Elastomers: The term is a shortened merging of “elastic polymers” and describes any polymer with viscoelastic properties. Elastomers are often thermoset (requiring vulcanisation, like natural rubber for example), though some are more thermoplastic as for example the block copolymers used for adhesives.

Ester: A chemical compound derived from an acid—whether organic or inorganic—in which the “acid” function has been reacted with an alcohol. Rosin esters are sometimes used as resins for the formulation of hot melt adhesives to give increased adhesive strength. They are esters of rosin acid, such as abietic acid.

EVA: Ethylene-vinyl acetate—a copolymer obtained by polymerising ethylene and vinyl acetate monomers. An EVA-based hot melt is an adhesive formulated with EVA as the backbone polymer.

Evocation: One part of the adhesive odour test—along with intensity and hedonic note, evocation asks “what does it smell like?” For all of us, as consumers, odours are powerful triggers for memory and emotion, and can have a strong impact on our view of a product. The objective of using a trained panel is to be able to forget memory and emotion and use a common language to describe evocation. For example, “It smells like dimethyl sulphide” instead of “It smells like cabbage.”

Failure mode: The way that a bond between two substrates—created by an adhesive—can fail. Ideally, when a force is applied to separate the two materials, it is expected that one of the materials will fail, not the adhesive. This would be called “substrate failure.” When the substrate is particularly durable, the adhesive itself may break. This is called “cohesive failure.” And finally, if the applied force breaks the adhesive’s grip on the substrate, this is called “adhesive failure.” Adhesive failure may indicate the adhesive is not chosen correctly to adhere to the substrate. Bostik typically determines both adhesive performance and failure modes for adhesives.

Fluorescing agent: A chemical which absorbs UV light and re-emits blue light, according to the principle of fluorescence. Also called optical brighteners, fluorescing agents may be added to adhesives to reveal the presence and placement of the adhesive. A UV lamp is placed on the production line to “excite” the fluorescing agent and a camera will pick up the coloured response to determine presence. Some adhesives have inherent fluorescing properties, but they are generally not as pronounced as if a fluorescing agent were added.

Formulation: A mixture made according to a recipe of the specific ingredients. Each hot melt adhesive has a unique formulation. Bostik’s recipes are based on knowledge of raw materials combined with the needed specifications. These include the adhesive’s expected performance, application parameters, cost, and regulatory aspects, etc.

Fourier transform infrared spectroscopy (FTIR): Infrared spectroscopy is a non-destructive analytical technique using infrared radiation. FTIR measures how the radiation is absorbed at various frequencies to determine the chemical composition of a sample. Fourier transform refers to the type of calculation used. This mathematical technique allows gathering more data faster, thus improving both signal to noise ratio and precision. FTIR is used to identify certain types of bulk contamination, surface contamination, and selected raw material characteristics.

Free radical: An uncharged molecule possessing an unpaired valence electron. As electrons like to be in pairs, a free radical will “scavenge” electrons from another molecule and create more free radicals. Because of this, free radicals are highly reactive and can start a chain reaction. Free radicals can be caused by exposure to oxygen, heat, light, or shear, and are a known cause of adhesive degradation.

Gardner colour: A colour value based on the Gardner scale of colours, from 1 (light) through 18 (dark). This scale is used for yellow to brown hues. To determine Gardner colour, a sample of adhesive is compared to references to evaluate aesthetics.

Gas chromatography-mass spectrum (GC-MS): An analytical method which combines the features of gas chromatography (GC) and mass spectrometry (MS). GC-MS is used to separate and then identify components of a sample. The principle of chromatography is to move a mixture of chemicals through a solid element via a carrier. The chemicals will have various affinities with the solid element. Because of this, they will pass through the solid element at differing rates, thus allowing them to be separated. Upon exiting the solid element, they go into a detector to be identified and quantified by comparison to pure chemicals. In gas chromatography a mixture of chemicals is vaporised and pushed by a gas. Their affinity to the solid element is based on their chemical structure. MS indicates that the detector is using mass spectrometry to identify the different chemicals by measuring their weights. In mass spectrometry, chemicals are decomposed in a magnetic field; the way they decompose and the weight of the different fragments can identify the chemical, when compared to available databases. GC-MS is useful in analysing volatile organic compounds (VOCs), like those present in hot melt adhesives, raw materials, and more.

Gel permeation chromatography (GPC): This analytical technique also uses the principle of chromatography (see GC-MS) In the case of GPC, the carrier is liquid and. affinity to the solid element is based on molecular weight. Therefore it is a test mostly used to identify the molecular weights of polymers. It can also be used to evaluate the ratios of adhesive raw materials, check for adhesive degradation, and identify the grade of polymer used.

Hedonic note: One part of the adhesive odour test, along with intensity and evocation, hedonic note asks, “Is it pleasant or unpleasant?”

Hot melt adhesive: An adhesive is a material used to assemble two or more components together, through the phenomenon of adhesion. A Hot melt adhesive is a thermoplastic material, solid at room temperature that will be heated and applied in liquid form to adhere to the substrate. As it cools, also called setup, it gains its cohesion. This ensures the bond between two or more substrates. Hot melt adhesives are commonly used in disposable hygiene products in any area where materials must be bonded together.

Hot Melt Wetness Indicator: A hot melt wetness indicator (HMWI) is an adhesive designed to change colour when exposed to an insult from inside the diaper. It is used to alert the parent or caregiver that the diaper may need changing.

Hydrocarbon: An organic compound that is made only of hydrogen and carbon atoms (HYDROgen + CARBON). Hydrocarbons are often derived from petroleum or natural gas.

Hydrocarbon resins: Resins obtained by polymerisation of specific cuts of hydrocarbons obtained from petroleum feedstocks. Hydrocarbon resins can be divided into several categories with differing properties based on the type of hydrocarbons that are used. They can also be hydrogenated. Many types are useful in the formulation of adhesives.

Hydrogenation: The process of adding hydrogen atoms to a molecule, converting double or triple bonds to single or double. This changes the molecule’s structure and properties. Hydrogenated molecules are also generally more stable. Hydrogenated resins in particular are also typically lighter in colour, which may be considered important for product aesthetics.

Laminate: To overlay a flat material with at least one other flat material. In absorbent hygiene products, it often refers to combining a film with a nonwoven material. The result of laminating two layers is a laminate.

Leakage: Bodily fluids escaping from a disposable hygiene product during wear.

Loss modulus: An intrinsic property that measures how the adhesive behaves upon deformation. The loss modulus is one component of an adhesive’s modulus. Because hot melt adhesives are viscoelastic, their loss modulus measures viscous behaviour. The symbol for loss modulus is G”.

Mechanical adhesion: A type of adhesion that relies on physical interlocking of the two materials. Mechanical adhesion typically involves one or more porous materials, as seen in adhesion to paper or wood, or when an adhesive penetrates the pores of a substrate. For hot melt adhesives used in disposable hygiene products, mechanical adhesion can explain adhesion to fluff or nonwoven substrates.

Melting point: The temperature at which a solid changes to a liquid. Not all materials have melting points. Some, including many bio-based materials, burn. Others, such as hot melt adhesives, slowly soften and liquefy across a wider range of temperatures. (See Softening Point)

Metallocene PO (mPo): A type of polyolefin where the catalyst that promotes the polymer chain growth has a metallocene structure. The selection of catalysts can allow a precise and tailored structure, and weight of the polymer chains. It also provides the ability to create alternating crystalline and amorphous zones.. Typically, most mPos are a copolymer of ethylene or propylene with other hydrocarbons.

Micro phase domains: Describes the polymer morphology of styrenic block copolymers. Polystyrene domains are tough, brittle, and provide cohesion. Polyisoprene or polybutadiene domains are amorphous and elastic. Since they are incompatible, they create separate domains, although they are on the same polymer chains. The unique result is an elastic polymer that is strengthened by the cohesion of solidified polystyrene.

Midblock: The portion of a styrene block copolymers found between the two polystyrene ends. Two common midblocks are polyisoprene for SIS copolymers and polybutadiene for SBS. The type of midblock affects many properties of the adhesive.

Modulus: A measurement referring to the intrinsic properties of a material. In the context of adhesives, such as those used in disposable hygiene products, modulus is linked to the force an adhesive exerts when deformed. The science of rheology provides measurement of modulus mathematically, through determining a material’s storage modulus and loss modulus.

Molecular weight: The weight of a molecule, which depends on the number and types of atoms. It can affect how a substance behaves. For example, molecular weight will impact the viscosity of a polymer and may affect the volatility of a chemical.

Monomer: A single molecule that forms the repeating unit in a polymer.

Morphology: Refers to the physical organisation of polymer molecules within the material. Morphology can greatly affect how a material behaves in different circumstances.

Multi-purpose adhesive: A multi-purpose adhesive is a single adhesive that meets a customer’s performance needs of multiple products. In hygiene the use of a multi-purpose adhesive would typically replace the need to use separate construction and elastic attachment adhesives.

Naphtha: A flammable oil containing a variety of hydrocarbons, naphtha may be obtained from coal but more often from crude and shale oil. Naphtha is used as feedstock for the petrochemical industry. It is transformed by steam-cracking into ethylene, propylene, and other olefins.

Nonwovens: As defined by EDANA and INDA, a nonwoven is “a sheet of fibres, continuous filaments, or chopped yarns of any nature or origin, that have been formed into a web by any means, and bonded together by any means, with the exception of weaving or knitting.” Nonwoven materials are often used as substrates in disposable hygiene products.

Odour intensity: One part of the adhesive odour test, along with evocation and hedonic note, that rates the strength of the odour. A trained panel must be able to assess intensity aside from hedonic tone.

Oil: One of the most common adhesive plasticiser classes in hot melt adhesives. Oil is mainly used to regulate adhesive viscosity, which is critical to the processing of the adhesive. Most oils are obtained by distillation of crude or shale oil.

Olefin: Another term for an alkene, such as ethylene and propylene, or a material made from them. See Polyolefin.

Open time: The time an adhesive takes to travel from the nozzle to the compression zone, where it reaches the secondary substrate. Open time is an important factor in deciding the right adhesive for a given product and production line.

Organic compounds: In chemistry, this refers to compounds built with carbon covalently linked to other elements, such as hydrogen, oxygen, or nitrogen.

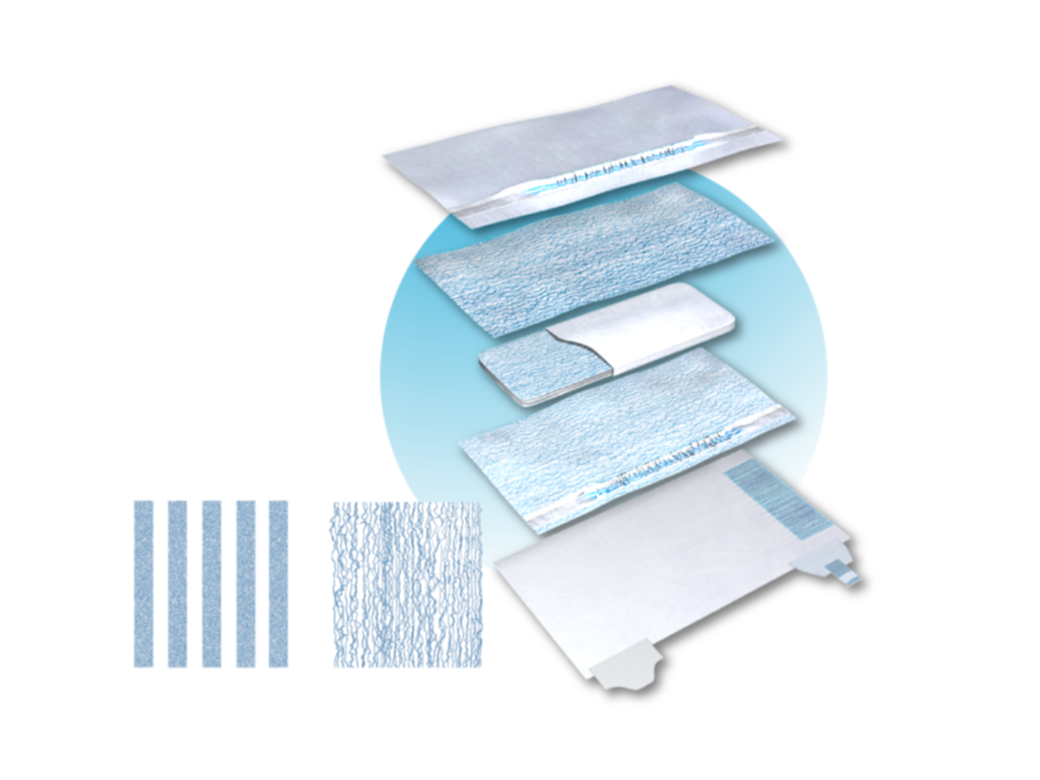

Pad attachment adhesives: Also called pad fastening adhesives or garment attachment adhesives, this type of adhesive is used to hold certain feminine hygiene and light adult incontinence products in place in the user’s underwear. The adhesive should provide a bond sufficient to give the consumer confidence that the pad will stay in place. It should not cause the pad to tear or leave residue when the article is removed.

Peel: The strain on an item or substance when a force is applied perpendicularly (away from the surface of the material). Producers may use peel to approximate the force needed to shift a feminine or adult incontinence pad affixed to underwear fabric, or to separate the materials in a laminate.

Penetration: How well or how deeply an adhesive seeps into a substrate.

Phasing: When two ingredients that were thoroughly mixed together separate from each other. Phasing can be a sign of adhesive degradation.

Plasticiser: A substance added to improve flexibility and make a material less brittle. Plasticisers in adhesives make them more durable and help prevent cohesive failure. Common adhesive plasticiser classes are oils, mainly used for pressure sensitive application, and waxes, more typically used with polyolefin or EVA based adhesives.

Polarity: The presence or direction of a positive/negative electron differential. Certain molecules are innately polarised due to their shape and internal chemical bonds. In addition, some materials, such as iron, are not innately polarised but can be given and retain polarity. Because polarity can affect the behaviour of certain chemicals under select conditions, they may be considered especially desirable or undesirable, depending on the adhesive’s application.

Polyethylene (PE): A polyolefin based on ethylene as a monomer. PE film is a low-cost, versatile plastic used in manufacturing disposable hygiene products, as well as grocery bags, food packaging, and many other everyday items.

Polymer: A chemical created by bonding together a large number of units, i.e., monomers, into a long chain. Polymers give adhesives internal, or cohesive, strength.

Polymer structure: The physical shape of a polymer molecule including its branches or loops. A polymer’s structure greatly affects its properties.

Polyolefin (PO): A common type of polymer with olefin(s) as monomer(s). Olefins are unsaturated hydrocarbons, such as ethylene and propylene. Depending on the catalyst used to promote chain growth, the polymer structure, crystallinity, and molecular weight can vary significantly. Polyolefins can be used in hot melt adhesives. Their traits vary based on a variety of factors, but they are generally thermoplastic, stiff, light, and hard. In addition, they are nonpolar and have low-to-medium cohesion and elasticity.

Polypropylene (PP): A type of polyolefin based on propylene as a monomer. PP film is known for its high strength-to-weight ratio, excellent chemical resistance, and high performance in corrosive environments. It is easily thermoformed and welded. Polypropylene has been used as the main component of nonwovens used in hygiene disposable products.

Porous: Having spaces or holes through which air or liquid may pass. Nonwoven is porous with macro-size spaces. Breathable polyethylene is porous with micro-size holes. Adhesives bond well to porous substrates such as nonwovens, but if the substrate is too porous, there can be adhesive bleedthrough.

Reactive adhesives: These adhesives are composed of ingredients that are able to undergo a chemical reaction during use. They are applied in a liquid form to wet out the substrate. A chemical reaction hardens the adhesive until it is set up and has enough cohesion to ensure a strong bond.

Residue: Traces of adhesive left on underwear fabric when a disposable hygiene article is removed. Choosing adhesives that meet performance expectations and leave no residue can improve consumer confidence and loyalty to your product.

Resin: Lower molecular weight polymers derived from naphtha or natural feedstock. Selecting the right resin can affect adhesive and cohesive strength, tack, and open time.

Rheology: The study of the deformation and flow of materials. Hot melt adhesives, for example, have an interesting behaviour that is called viscoelastic. Depending on temperature and deformation, their behaviour is a blend of elastic solid and a viscous liquid. Rheology helps determine the mechanical properties of adhesives in a wide temperature range. It can also distinguish elastic and viscous behaviours. Rheology can also predict how applied forces, i.e., pressure, bending, or twisting, will affect them.

Rheometer: A device used to carry out rheology testing. Bostik uses rheometers as a tool for modelling adhesive performance and processability.

Ring and ball test: Used to determine the temperature at which a material softens. Adhesives and resins do not transition from solid to liquid through a sharp melting point. Instead, they pass through a softening zone. The ring and ball test is one way to determine a point in this zone. The way it is carried out is as follows: A steel ball of specified weight is placed on a ring filled with the sample. It is then heated at a prescribed rate in a prescribed test liquid. At a certain temperature, the ball will fall through the ring. This temperature is called the softening point. It is an element in determining application temperature window and open time.

Set up: The period of time and/or action of an adhesive solidifying by losing its heat or carrier after “wet-out.” Appropriate set up is critical to an adhesive’s cohesion.

Setback temperatures: A recommended temporary drop in the temperature to reduce adhesive degradation when a production line is put on hold. Bostik can supply clients with setback information as appropriate for our adhesives.

Shear: The strain on an item or substance when force is applied laterally along the surface of the material. Shear strength is important for adhesives used in stress bonding applications. For example, in disposable hygiene, this would apply to diaper fastening and stretch materials.

Skin/skinning: The formation of a solid or gelled layer on top of a fluid. This can be a sign of degradation of the adhesive.

Softening point: Some materials, such as hot melt adhesives do not transition from solid to liquid at a single temperature, but instead gradually soften across a range of temperatures. For these materials, a standardised test, such as the ring and ball test, may be used to determine a single point in that transition. This softening point often reflects the “set point” of the adhesive, i.e., the point at which it stops flowing.

Solvent: A liquid in which other chemicals are dissolved.

Solvent-based adhesives: These adhesives have their ingredients dissolved in a solvent. The adhesive is applied in a liquid form. The solvent will then evaporate, leaving the adhesive in place to set up and create the bond. Solvent-based adhesives are not used in disposable hygiene products.

Static shear hang test: A method used to test shear performance of an adhesive, when the stress is static. In this test, two pieces of material are overlapped and adhered together. The top is then hung from a bar or clamp, while a weight is clamped to the bottom. The test measures time to failure. In a dynamic shear test, the two pieces would be separated at a certain speed until failure and the force is measured. Shear strength is important because adhesive failure can cause tabs to detach while the parent is fitting the diaper. Shear strength also helps prevent leakage or other failure of the product.

Staybility: A test created by Bostik, to demonstrate how well a feminine pad stays in place on an undergarment, preventing leakage that may occur as a result of movement during daily life.

Stay in place: The need for a wearable disposable hygiene pad not to shift or detach during use. This is accomplished through the use of pad attachment adhesives. Pad producers commonly use peel testing for measuring stay-in-place performance, although the forces involved are not technically the same. Bostik recommends the use of the Staybility test to measure pad stay in place performance.

Storage modulus: One of the components of the modulus of an adhesive, an intrinsic property that measures how the adhesive behaves upon a deformation. Because hot melt adhesives are viscoelastic, storage modulus measures the elastic behaviour of the material in an essentially solid state. The symbol for storage modulus is G’.

Strain: Another word for “deformation.” Testing can either 1) apply a force to measure the deformation it causes or 2) apply a deformation to measure the force exerted by the material to oppose the deformation. This is important to measure in high stress applications to avoid failure.

Stretch: Deformation due to pulling. Elastic strands can be stretched to a certain elongation. Certain portions of diapers and other disposable hygiene products are designed to stretch during use. In diapers, for example, these may include attachment ears, side panels, and belly panels. By extension, adhesives used to manufacture these elements may be called “stretch adhesives” or “elastic adhesives.”

Styrene: An aromatic hydrocarbon derived from benzene. Styrene is often used to make polymers such as polystyrenes to be used in a foam or solid, copolymers referred to as synthetic rubbers to be used in a latex or solid, and resins. Copolymers with polystyrene blocks at both ends are known as styrenic block copolymers and are broadly used for hot melt adhesive formulation.

Styrenic block copolymers (SBc): Copolymers with a block structure, composed of blocks of polystyrene at both ends with a block of various rubbers in the middle. Common midblocks are polyisoprene (the SBc will be called SIS) or polybutadiene (SBS). Both have a wide range of formulation and application uses.

Styrene-butadiene-styrene (SBS): A styrenic block copolymer with a polybutadiene midblock.

Styrene ethylene butylene styrene (SEBS): A styrenic block copolymer that is a hydrogenated version of SBS. A common substitute where PVC was once used, for example, in toys. Also an alternative to SBS when high UV resistance or thermal stability are needed.

Styrene-isoprene-styrene (SIS): A styrenic block copolymer with a polyisoprene midblock.

Substrate: A conventional way to describe a material to which adhesive will be applied. A substrate’s strength and softness are important considerations in product design. Understanding a substrate’s properties is important before recommending or selecting an adhesive or other bonding technology, as not all methods work with all substrates.

Superabsorbent polymer (SAP): A synthetic polymer that has the remarkable ability to retain large volumes of fluid relative to weight, even under pressure. It is now an essential component of the core of absorbent hygiene products. SAP is most often used in combination with fluff, although some newer core designs do not use fluff.

Surface energy: A physical property used to predict a substrate’s wettability. The term surface energy is derived from the fact that it takes energy to break intermolecular bonds in the liquid so that it will spread out. If the surface energy of the substrate, with the help of gravity, can overcome the surface tension of the liquid being applied— an adhesive or ink, for example—then the liquid will wet out. If not, the liquid may spread poorly or simply bead on the surface. Corona treatment can be used to increase the substrate’s surface energy and improve wettability.

Surface tension: Although molecules in a liquid are free-flowing, they tend to pull together—such as water droplets merging or liquids beading. This is also why water droplets are mostly spherical. Surface tension is a measure of the liquid’s tendency to pull together. When a liquid meets a solid surface that has a higher surface energy, that energy is able to overcome the surface tension and get the liquid to spread at the surface of the solid. Otherwise, the liquid will stay as a droplet on the surface. This is how an adhesive or an ink can or cannot wet out a surface and adhere to it.

Tack: Describes an adhesive’s ability to create a bond under light pressure and in a short period of time. Adhesives that present tack are called “pressure sensitive” adhesives. They feel “sticky” to the fingers. An adhesive needs tack to create a bond rapidly under low pressure.

Tan delta (TD): Also called loss tangent, tan delta indicates an adhesive’s tendency to flow. In the terms of rheology, it is calculated as G”/G’, the ratio of a fluid’s lost energy (elastic) to its stored energy (viscous). For example, imagine dropping a ball made of the material. If it bounces back to the same height, it is very elastic and the energy lost is zero; all the energy is stored and given back. This indicates the tan delta is zero. Conversely, if the material is very viscous, it will not bounce back; it will stay flat on the ground. In this case, all the energy was lost—converted into heat or deforming the ball, for example.

Terpene resins: Naturally occurring resins based on isoprene units. Terpene resins are commonly derived from wood or citrus. They can be used to formulate adhesives with excellent adhesion.

Thermal bonding: Also known as heat bonding or melt bonding. Thermal bonding involves applying heat directly to two or more materials to bond them together. In disposable hygiene applications, this may be accomplished using a narrow gear-like wheel which is kept at a constant, high temperature.

Thermal stability: The degree to which a substance will hold its properties and qualities after prolonged storage at high temperatures. Thermal stability testing is used to determine whether an adhesive may be impacted after long storage times in the melt tanks on the production line.

Thermogravimetric analysis (TGA): Measures the amount and rate of change in the weight of a sample when progressively heated to a very high temperature.

Thermoplastic: Thermoplastic materials (or thermoplastics) are able to soften and melt upon application of heat, and solidify upon cooling. They may also retain their properties through repeated heating and cooling cycles. Examples include plastic polymers that are processed in the softened or melted state via extrusion or molding, and will resolidify upon cooling for their final shape. And they can be recycled via re-melting Hot melt adhesives are thermoplastic and solid at room temperature.

Thermoplasticity: Describes the extent to which a substance melts or softens at higher temperatures—as opposed to burning, for example. Hot melt adhesives have a high degree of thermoplasticity. Substrates with a low thermoplasticity do not melt, and therefore are not good candidates for ultrasonic bonding.

Thermoset rubbers: An elastomer that is set (hardened) by use of high heat.

Ultrasonic bonding (USB): Also known as ultrasonic welding. USB is a process which uses high-frequency (ultrasonic) sound waves to fuse two or more substrates. The ultrasonic energy creates localised partial melting where the substrates are pressed together. Once the sound waves cut off, the materials cool quickly, creating a bond. Because of this, the substrates to be bonded must be thermoplastic and have similar melting points. USB permanently bonds the materials.

UV: Ultraviolet is an electromagnetic radiation extending below violet light, towards X ray. UV radiation is invisible to the human eye. The energy of UV radiation can cause reactions within some materials, degrading them or changing their colour.

Van der Waals forces: The weakest of all intermolecular forces. Van der Waals forces do not rely on the actual sharing or attraction of electrons, but instead weak electrostatic forces.

Viscosity:The property of a fluid that resists forces causing it to flow. Measuring viscosity of a hot melt adhesive at high temperature, when it is liquid, is critical to understand 1) how the adhesive will be pumped through the application system, and 2) how it will flow on the surface of—and into—the substrate.

Volatility: In general chemistry terms, it is the rate at which a chemical compound evaporates. The higher the temperature—or the lower the pressure—the higher the volatility. Therefore, a high volatility compound, or a material that contains high volatility compounds, is susceptible of releasing molecules in gaseous form. These molecules (which are organic and therefore sometimes called volatile organic compounds) may be detectable by smell.

Water-based adhesives: Water-based adhesives have their ingredients dispersed in water, and they are applied in liquid form to adhere to the substrates. The water evaporates for the adhesive to set up and provide the final bond.

Wet-out: The action of the adhesive flowing and spreading on the surface of a substrate. The objective is to maximise contact area at the interface between adhesive and substrate but stay within the desired area.

Wettability: The ability of a fluid to spread on, and potentially adhere to, a solid surface. Low wettability indicates the liquid may bead instead of wetting the surface.

Wingdot adhesive: A temporary or fugitive (low-tack) adhesive dot used to hold disposable hygiene pad wings in place during final production and packaging.

Other glossaries from Bostik include:

CODE: USB-21A01

Adhesives and Bonding Materials from Bostik Academy

Click the links below to sign-in and access all of our Academy materials.