Bostik’s Conditioned Core Integrity Test

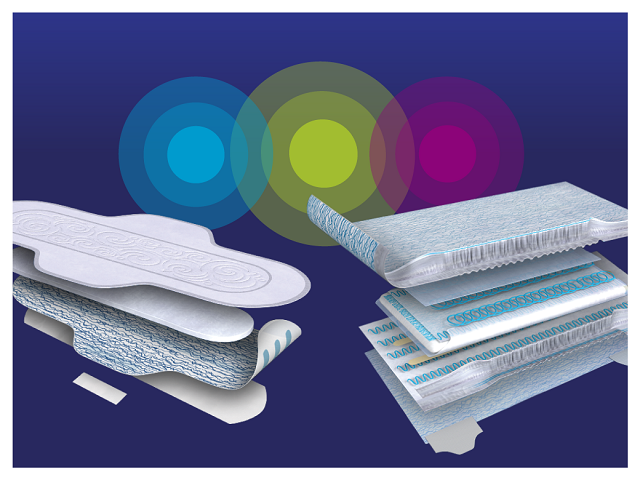

Disposable diapers come in many shapes and sizes. But whether for baby care or adult incontinence, they all have one thing in common: the absorbent core. Testing its integrity is a valuable method to help you ensure your products meet consumer expectations.

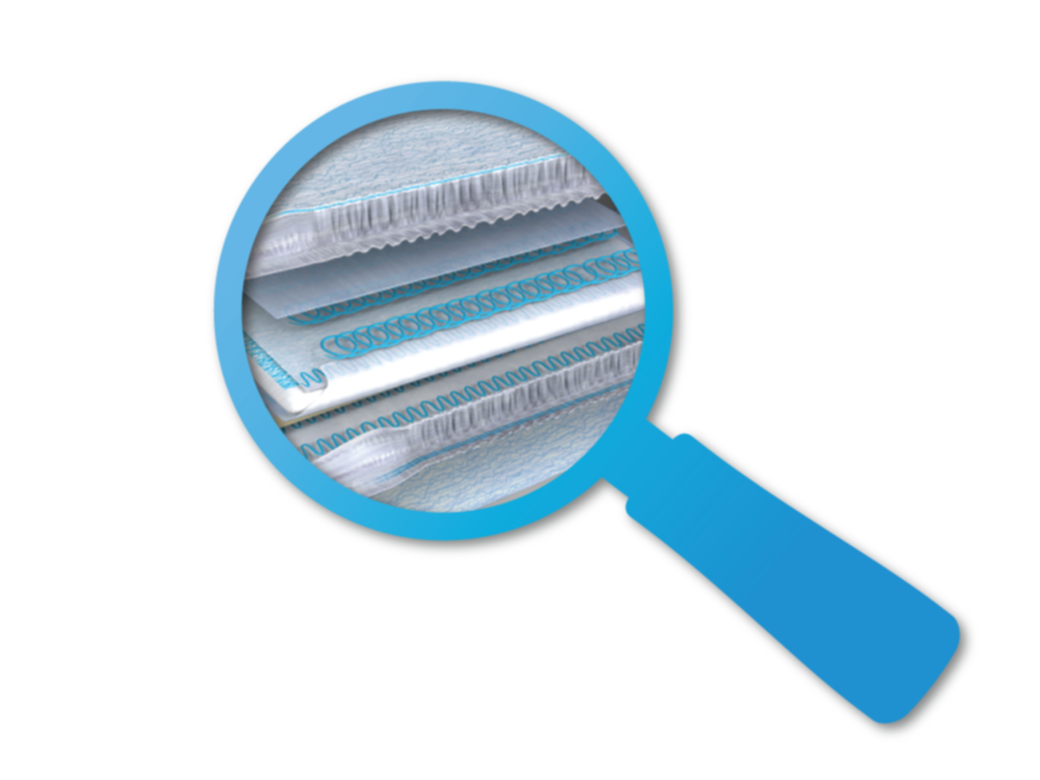

One failure mode in traditional and channel cores is called ‘cracking’. This is when the core’s absorbent materials separate into clumps, leaving gaps. The resulting crack allows some fluid to escape—causing leaks—instead of the entire insult being absorbed.

Evaluating core integrity … will it crack?

Core integrity tests range from using simple tools to employing complex equipment. All exert force directly on a wet core for a specified length of time. This is done through spinning, shaking, swinging, or a series of drops. These methods may provide some measure of quantitative data for core cracking in a wet diaper. However, they do not reflect the realities of abuse that a diaper endures before an insult.

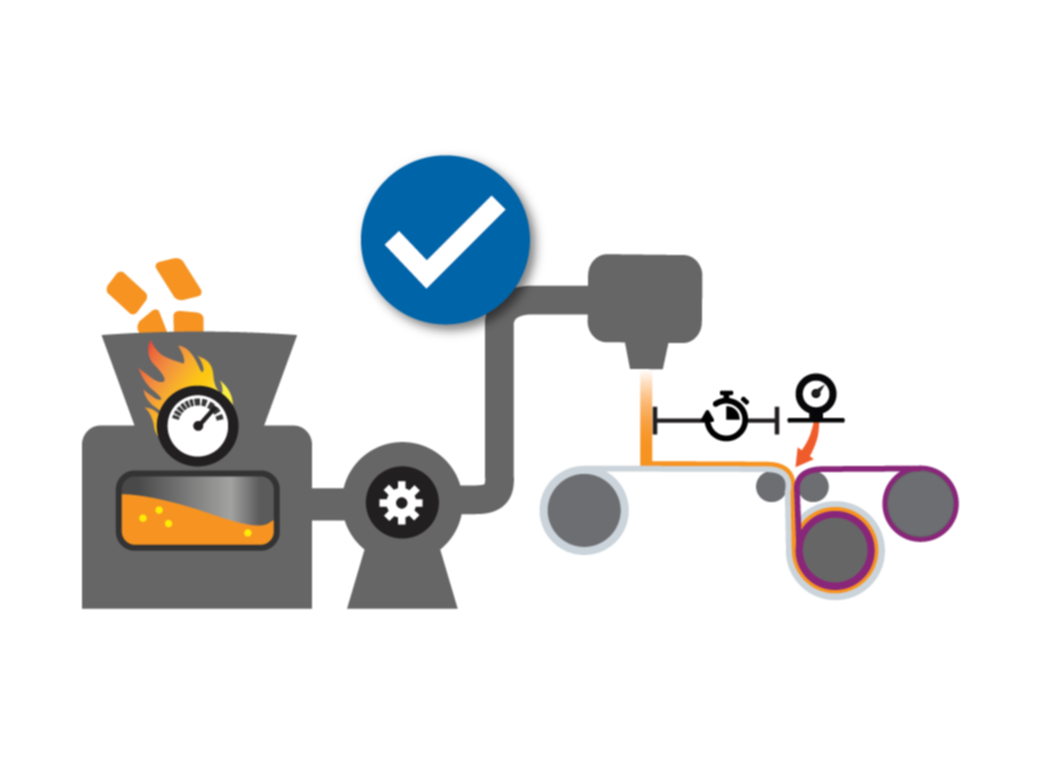

Bostik takes a more holistic approach: We add an extra step to create the Conditioned Core Integrity Test[EC2] . This preconditioned component allows us to evaluate core integrity when a diaper is both wet and dry.

The process involves:

- Defining where we want the insult point to be on the core

- Preconditioning the diaper to simulate the movements of a wearer whilst the diaper is still dry

- Wetting the defined insult point with saline solution

- Waiting 5 minutes for the saline to absorb into the core

- Repeating the movement simulation until a core crack appears

- Recording the number of drops and extent of the crack

At Bostik, we understand that adhesives help manufacturers like you give consumers the level of performance they want. This is especially true as product cores become thinner or new core designs are introduced.

Additional services from Bostik

We offer a variety of informative next-level tests to help measure product performance and integrity. When you request a product audit, our trained professionals will thoroughly evaluate finished articles taken from your lines. We will also provide recommendations to overcome any integrity issues we find. Learn more about product audits.

CODE: CO-22A11